Waste gas treatment device employing coupling of ultraviolet catalytic oxidation and double-layer bio-trickling filter

An exhaust gas treatment device, catalytic oxidation technology, applied in the direction of gas treatment, chemical/physical process, catalyst activation/preparation, etc., can solve the problems of clogged void channels, low operating costs, large processing capacity, etc. Reasonable fluid bed distribution and the effect of improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

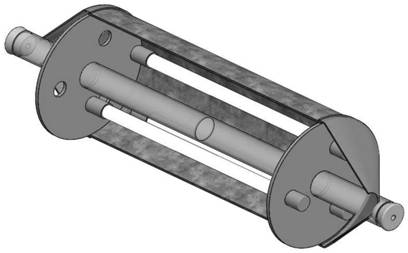

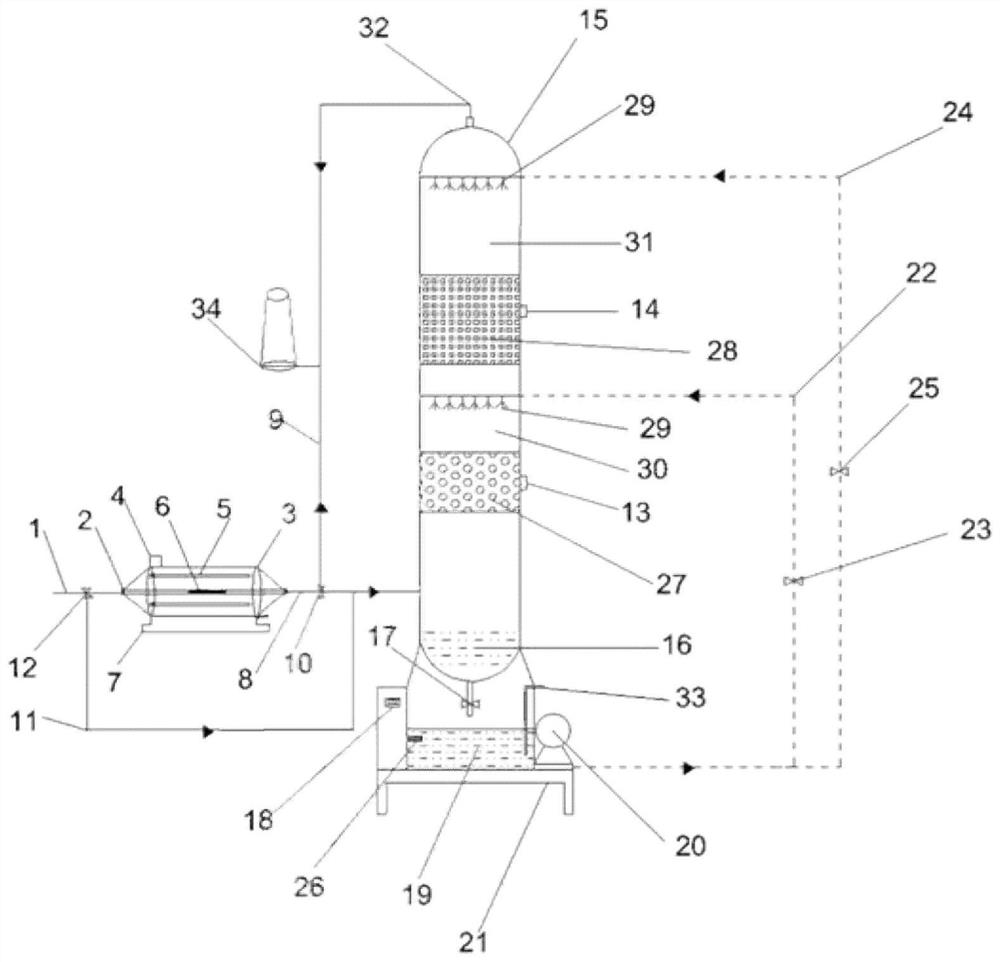

[0037] see figure 1 As shown, the present invention provides a waste gas treatment device for combined use of ultraviolet photocatalytic oxidation and double-layer bio-trickling filter tower, including an air intake pipe 1, a quartz catalytic oxidation pipe 2, a stainless steel cavity 3, a first electrical control box 4, a UV Ultraviolet lamp 5, MnOx / SiC composite photocatalyst 6, base 7, air intake pipeline 8, emergency exhaust pipeline 9, first emergency valve 10, emergency pipeline 11, second emergency valve 12, lower inspection port 13, upper inspection Port 14, double-layer trickling filter tower 15, circulating water layer 16, flow control valve 17, second electrical control box 18, nutrient solution storage tank 19, circulating pump 20, dripping filter tower base 21, lower circulating water pipe 22, lower electromagnetic Flow control valve 23, upper circulating water pipe 24, upper electromagnetic flow control valve 25, liquid level gauge 26, polyurethane biological bed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com