A catalytic ceramic sintered ring for exhaust gas treatment and its preparation method

A waste gas treatment and sintering ring technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of incomplete purification and achieve the effect of no dead knot in combustion, no overheating sintering, and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

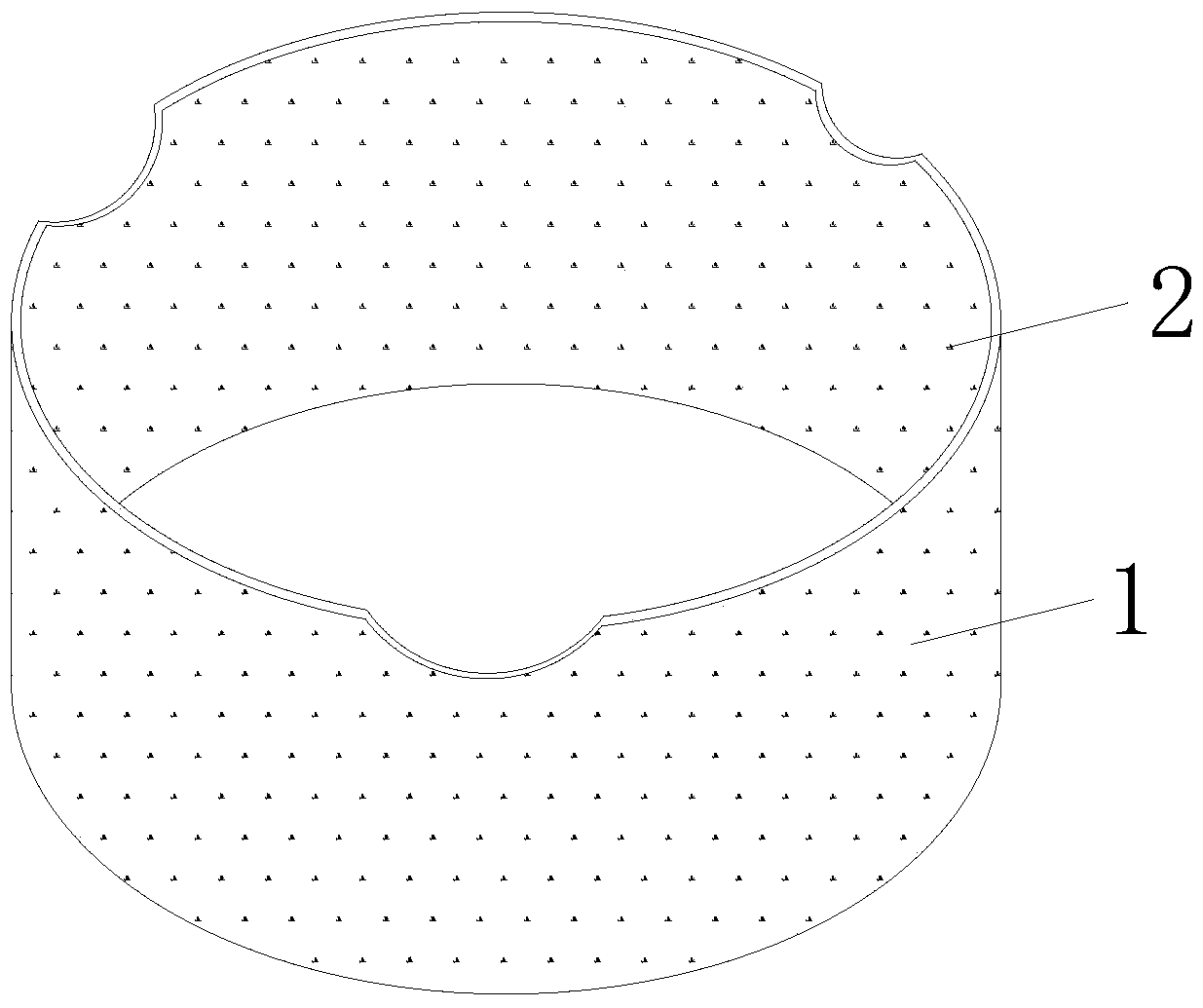

Image

Examples

Embodiment 1

[0032] The preparation steps of the catalytic ceramic sintered ring 1 include:

[0033]Step 1: 3kg of alumina, 4kg of titanium dioxide, 4kg of iron oxide, 4kg of zirconia, 4kg of lanthanum oxide, 3kg of cerium oxide, 4kg of praseodymium oxide, 4kg of zinc oxide, 30kg of activated carbon powder, and 40kg of silicon carbide are batched, wherein the The particle size of silicon carbide is ≤7 microns, the particle size of aluminum oxide, zinc oxide, and iron oxide is ≤100 nm, the particle size of zirconia is ≤90 nm, and the particle size of lanthanum oxide, cerium oxide, and praseodymium oxide is ≤40 nm. Described titanium dioxide particle diameter≤40 nanometers, pass 250-400 mesh sieve after described activated carbon powder is milled;

[0034] Step 2: Put 3kg of alumina, 4kg of titanium dioxide, 4kg of iron oxide, 4kg of zirconia, 4kg of lanthanum oxide, 3kg of cerium oxide, 4kg of praseodymium oxide, 4kg of zinc oxide, 30kg of activated carbon powder and 40kg of silicon carbide...

Embodiment 2

[0037] The preparation steps of the catalytic ceramic sintered ring 1 include:

[0038] Step 1: 2kg of alumina, 3kg of titanium dioxide, 3kg of iron oxide, 3kg of zirconia, 4kg of lanthanum oxide, 3kg of cerium oxide, 2kg of praseodymium oxide, 4kg of zinc oxide, 35kg of activated carbon powder, and 41kg of silicon carbide are used for batching, wherein the The particle size of silicon carbide is ≤7 microns, the particle size of aluminum oxide, zinc oxide, and iron oxide is ≤100 nm, the particle size of zirconia is ≤90 nm, and the particle size of lanthanum oxide, cerium oxide, and praseodymium oxide is ≤40 nm. Described titanium dioxide particle diameter≤40 nanometers, pass 250-400 mesh sieve after described activated carbon powder is milled;

[0039] Step 2: Put 2kg of alumina, 3kg of titanium dioxide, 3kg of iron oxide, 3kg of zirconia, 4kg of lanthanum oxide, 3kg of cerium oxide, 2kg of praseodymium oxide, 4kg of zinc oxide, 35kg of activated carbon powder and 41kg of sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com