Screen printing machine

A technology of printing machine and screen, applied in the field of screen printing machine, can solve the problems of misalignment or tilt, loose fixation, influence of screen printing effect, etc., to achieve the effect of strengthening printing effect and not easy to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

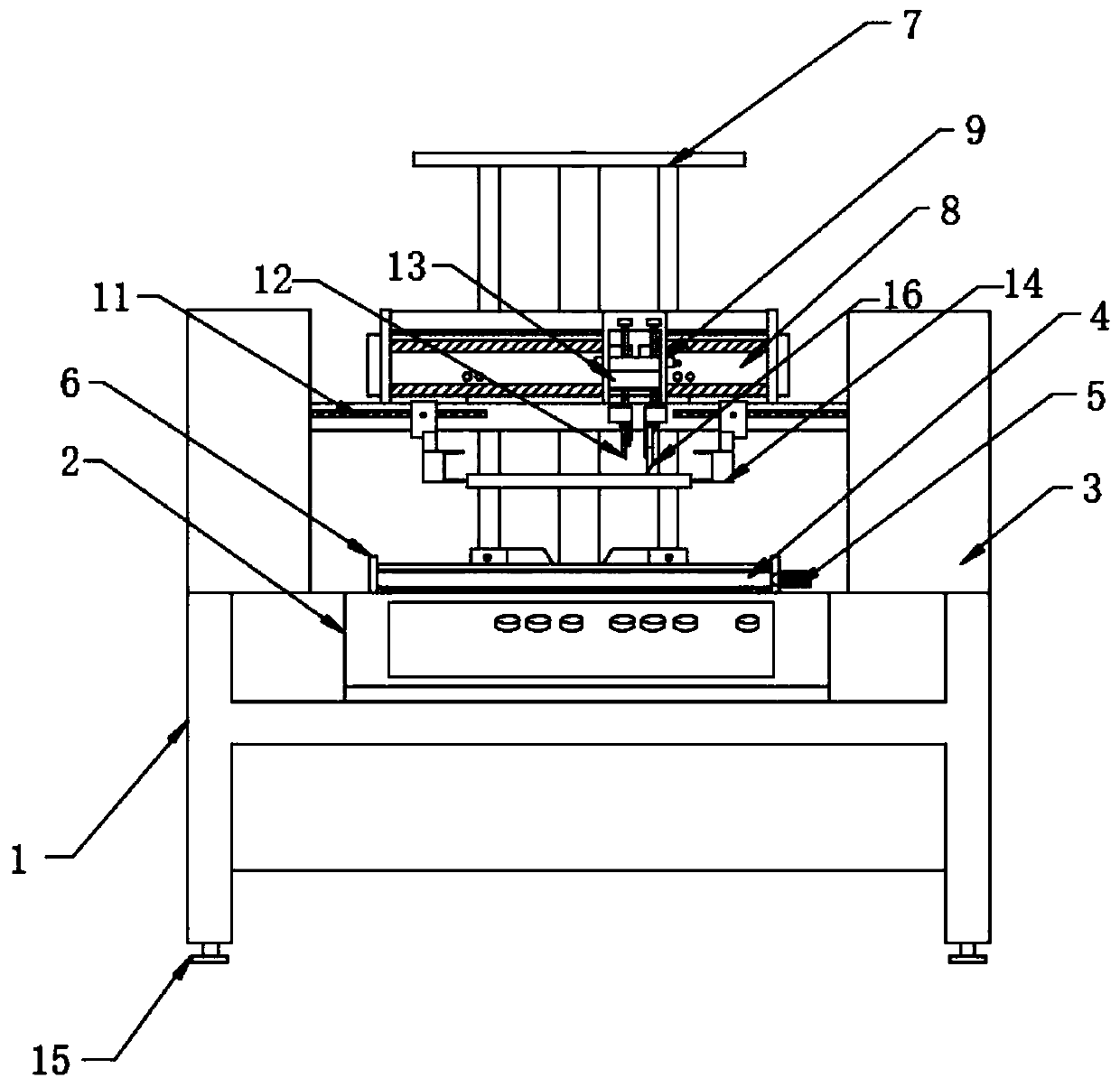

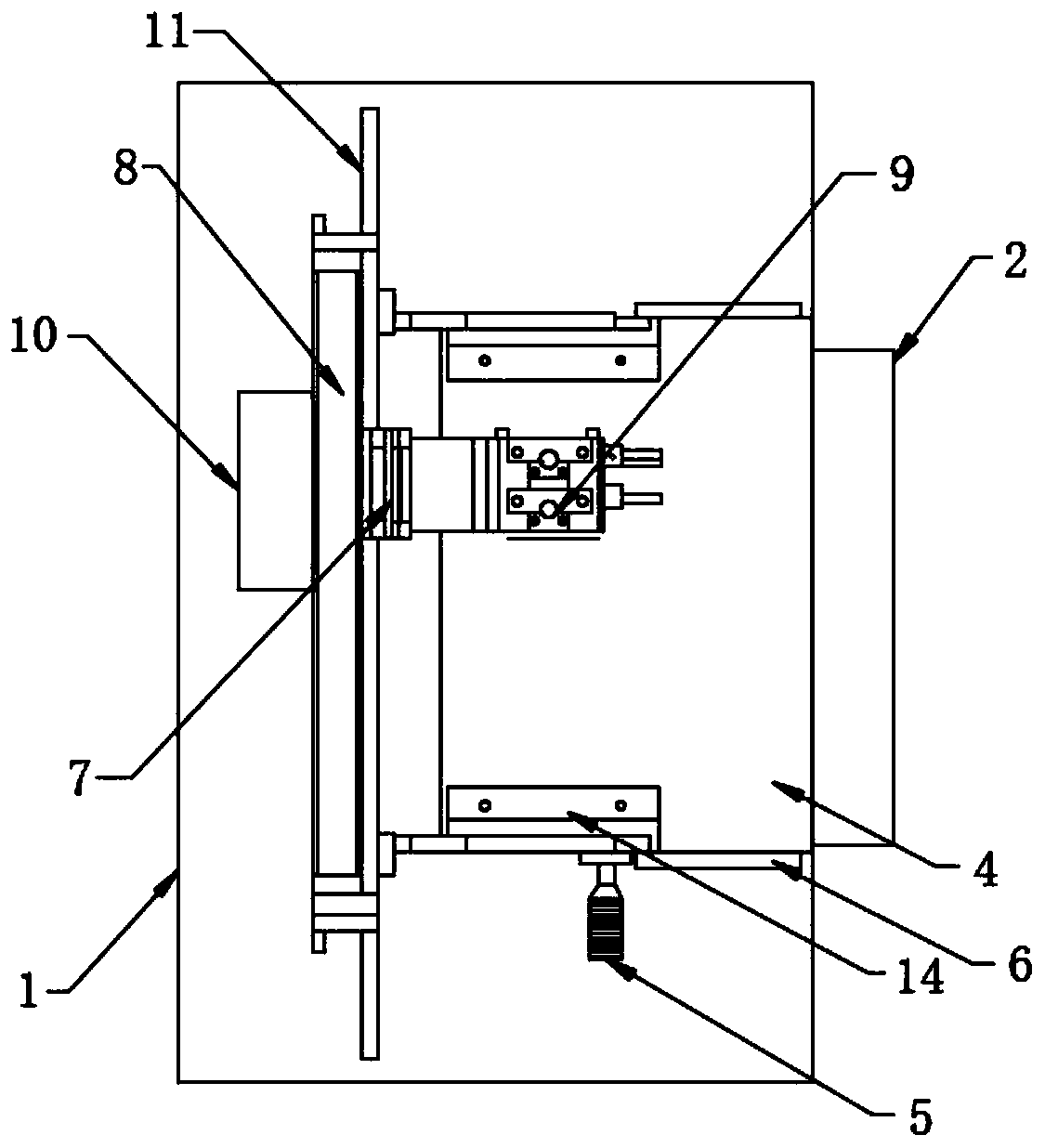

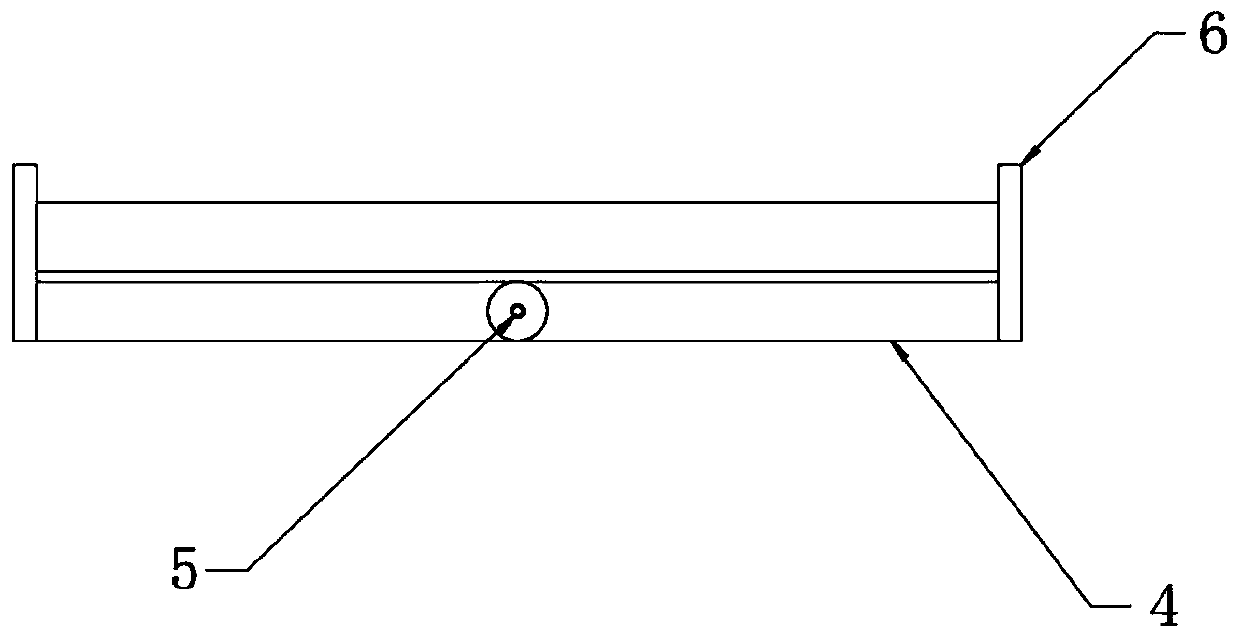

[0023] like Figure 1-3 As shown, the present invention provides a screen printing machine, including a workbench 1, a console 2 is arranged on the front surface of the workbench 1, baffles 3 are arranged on both sides of the top of the body 1, and an operation panel is arranged on the top of the workbench 1. Table 4, one side of the console 4 is provided with a fine-tuning handle 5, the two sides of the console 4 are also provided with fixing grooves 6, and the top of the table 1 is also provided with a vertical traveling mechanism 7, and the vertical traveling mechanism 7 is located on the console 4 The rear end face of the vertical travel mechanism 7 is clamped with a transverse travel mechanism 8, the outside of the lateral travel mechanism 8 is clamped with a printing head 9, the back end surface of the workbench 1 is provided with a first cylinder 10, and the lateral travel mechanism 8 A stencil clamping device 11 is provided at the bottom, several bases 15 are provided ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap