Movable building block stacking-packaging system

A stacking and block technology, which is applied in packaging, building materials packaging, transportation and packaging, etc., can solve the problems of labor waste, large labor occupation and shipping time, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

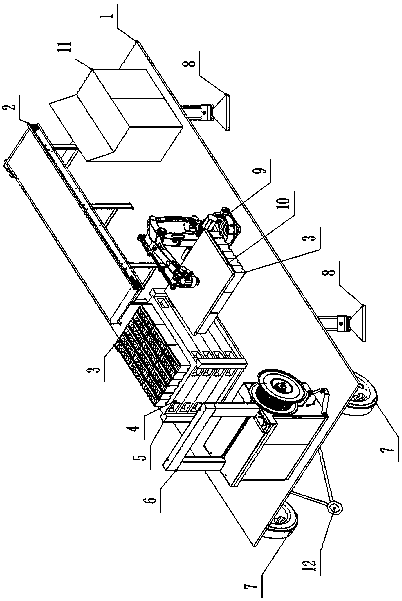

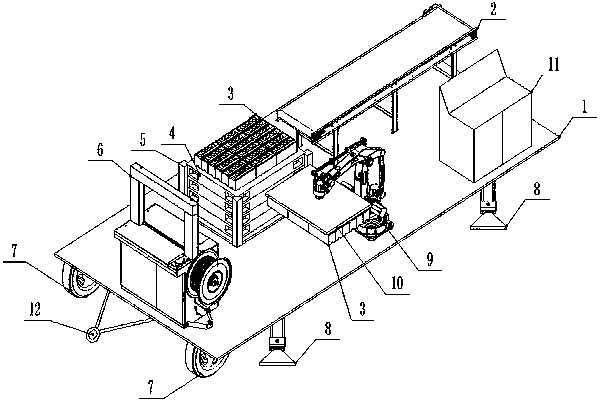

[0012] With reference to the figures covered in the accompanying drawings and specific practical instructions are as follows:

[0013] As shown in the figure, a mobile block stacking and packaging system is equipped with a plurality of universal adjustment wheels 7 on the lower side of the mobile platform 1, through which the multi-directional adjustment wheels 7 can be automatically adjusted. A plurality of hydraulic support seats 8 are installed at the same time around, and the hydraulic support seats 8 are used to support and fix the mobile platform 1. A block conveying alignment mechanism 2 is installed on the upper side of the mobile platform 1, and then the alignment mechanism 2 is installed on the block conveying alignment The front end of the mechanism 2 is equipped with an automatic pallet feeding mechanism 5, which can put multiple block pallets 4 at one time, and stack the blocks 3 according to a certain number of blocks through the stacking manipulator 9 installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com