EVA seamless buffer pipe for membrane product packaging

A technology of product packaging and buffer tubes, applied in the field of EVA seamless buffer tubes, can solve the problems of easily damaged lithium battery diaphragms, increased production costs, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

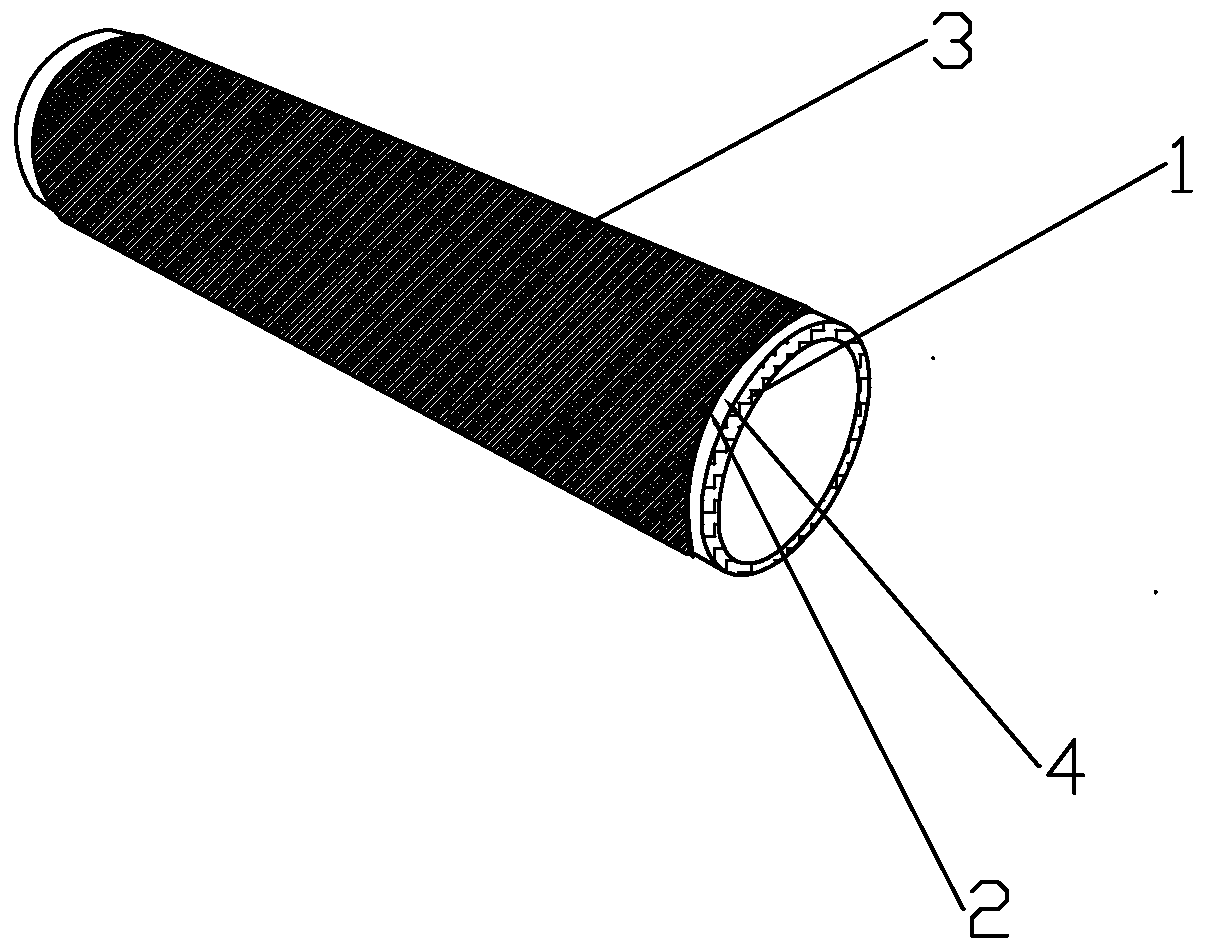

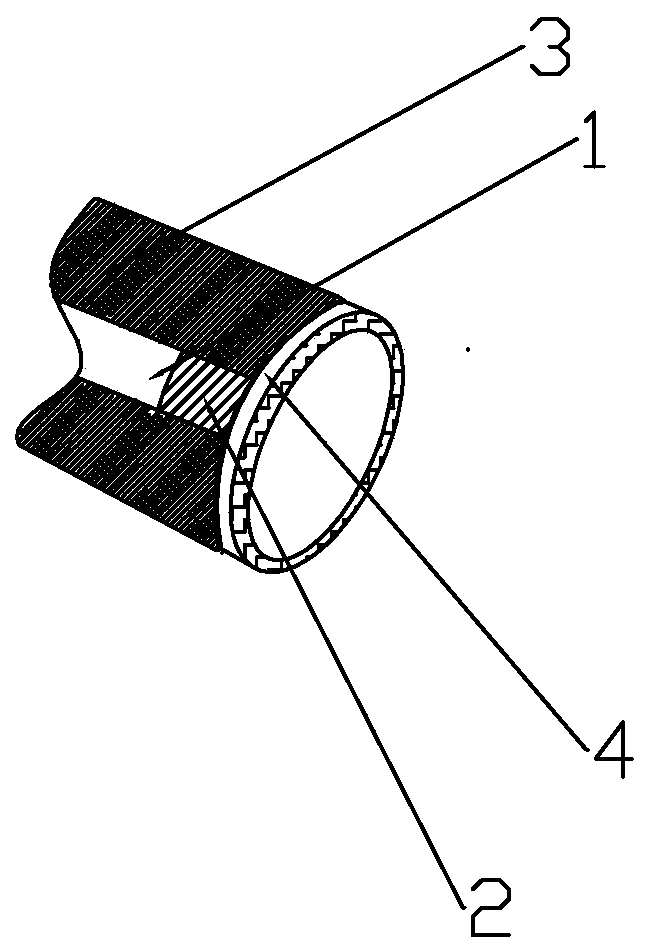

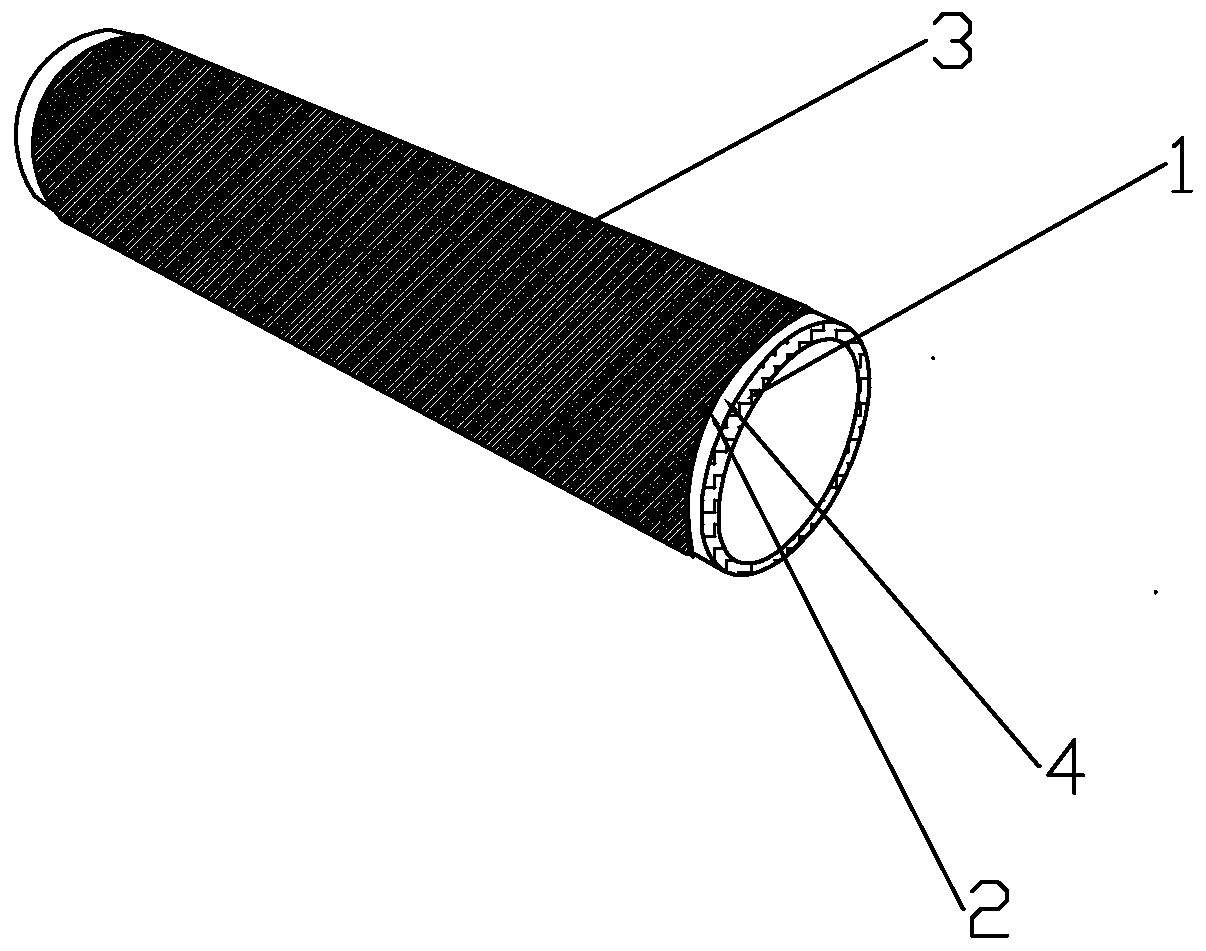

[0025] Such as figure 1 and figure 2 As shown, an EVA seamless buffer tube for film product packaging includes an inner tube 1, two adhesive rings 2 and an EVA buffer outer tube 3; the inner tube 1 is longer than the EVA buffer outer tube 3, And the inner tube 1 is inserted in the EVA buffer outer tube 3, and the two ends of the inner tube 1 are exposed to a transition end 4 at both ends of the EVA buffer outer tube 3 with equal lengths; Two bonding rings 2 are respectively bonded on the inner walls of the two ends of the EVA buffer outer tube 3, and the EVA buffer outer tube 3 is firmly bonded to the inner tube 1; the EVA buffer outer tube 3 includes the following percentages: Component raw materials: EVA particles 60%-63%, foaming agent 3%-5%, bridging agent DCP1%-1.2%, toner 0.4%-0.6%, polyacrylate 20%-25%, stabilizer 4%-6%, anti-aging agent 3%-5%.

[0026] At the same time, the EVA buffer outer tube 3 is integrally formed, the runout value of the surface finish is less...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com