Remaining active sludge deep process decrement method

A technology for residual activity and sludge, which is applied in the fields of sludge treatment, pyrolysis treatment of sludge, chemical instruments and methods, etc., can solve the problems of large amount of chemical agent, low reduction efficiency, poor stability, etc., and achieve the treatment cost. Low, good reduction effect, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

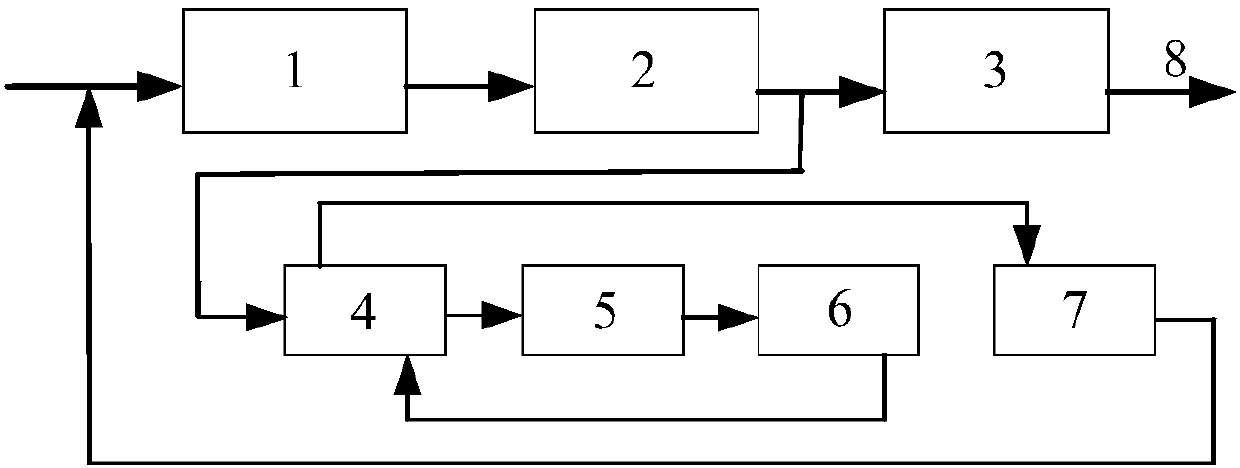

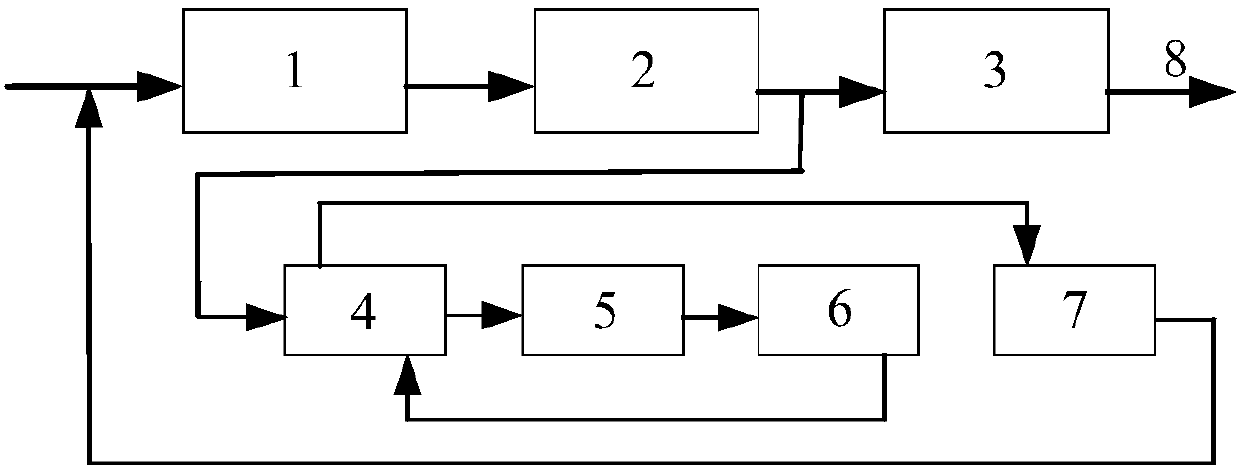

[0030] Such as figure 1 Shown, the embodiment of a kind of excess activated sludge depth process reduction method of the present invention is as follows:

[0031] (1) Sewage enters the sewage biochemical treatment system 1 for biochemical treatment. The sewage biochemical treatment system 1 is filled with hydrophilic biological fillers, which can be suspended formaldehyde vinylon silk fillers, or hydrophilic modified polyethylene, polyester, etc. Propylene or polyurethane suspension filler, the filling volume ratio in the sewage biochemical treatment system 1 is 20-50%, and the preferred range is 30-40%;

[0032] (2) The remaining activated sludge after the biochemical treatment in step (1) enters the remaining activated sludge concentration system 2. The required concentration range of the concentrated sludge is 5-30g / L, and a part of the concentrated remaining activated sludge enters the remaining active sludge The sludge dewatering system 3 performs dehydration treatment, ...

Embodiment 1

[0038] Characteristics of residual activated sludge: 1m of sludge in the biochemical treatment process sludge thickening tank of a sewage treatment plant 3 , the sludge indicators are: mixed suspended solids concentration (MLSS) is 16.8g / L, mixed liquor volatile suspended solids concentration (MLVSS) is 11.9g / L, organic matter percentage is 70.8%.

[0039] The implementation steps of the above-mentioned residual activated sludge treatment are as follows:

[0040] (1) The sewage enters the sewage biochemical treatment system 1. The sewage biochemical treatment system 1 is filled with hydrophilic biological fillers. The filling volume ratio in the sewage biochemical treatment system 1 is 30%, and the biological fillers are hydrophilic modified polyurethane porous suspension fillers. ;

[0041] (2) The excess activated sludge after the biochemical treatment in step (1) enters the excess activated sludge concentration system 2, and a part of the concentrated excess activated sludge...

Embodiment 2

[0048] Characteristics of residual activated sludge: 1m of sludge in the biochemical treatment process sludge thickening tank of a sewage treatment plant 3 , the sludge indicators are: mixed suspended solids concentration (MLSS) is 16.8g / L, mixed liquor volatile suspended solids concentration (MLVSS) is 11.9g / L, organic matter percentage is 70.8%.

[0049] The implementation steps of the above-mentioned residual activated sludge treatment are as follows:

[0050] (1) The sewage enters the sewage biochemical treatment system 1. The sewage biochemical treatment system 1 is filled with hydrophilic biological fillers. The filling volume ratio in the sewage biochemical treatment system 1 is 20%, and the biological fillers are hydrophilic modified polyethylene suspension fillers. ;

[0051] (2) The excess activated sludge after the biochemical treatment in step (1) enters the excess activated sludge concentration system 2, and a part of the concentrated excess activated sludge ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com