A kind of high-performance pedot-tellurium nanoparticle composite film and its preparation method

A composite thin film and tellurium nanotechnology, which is applied in the field of high-performance PEDOT-Te nanoparticle composite thin film and its preparation, can solve the problems of rough surface of the thin film, low increase efficiency, and reduced goodness, so as to achieve a high stability of the reaction process and improve mechanical properties. Strength, effect of inhibiting dissociation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

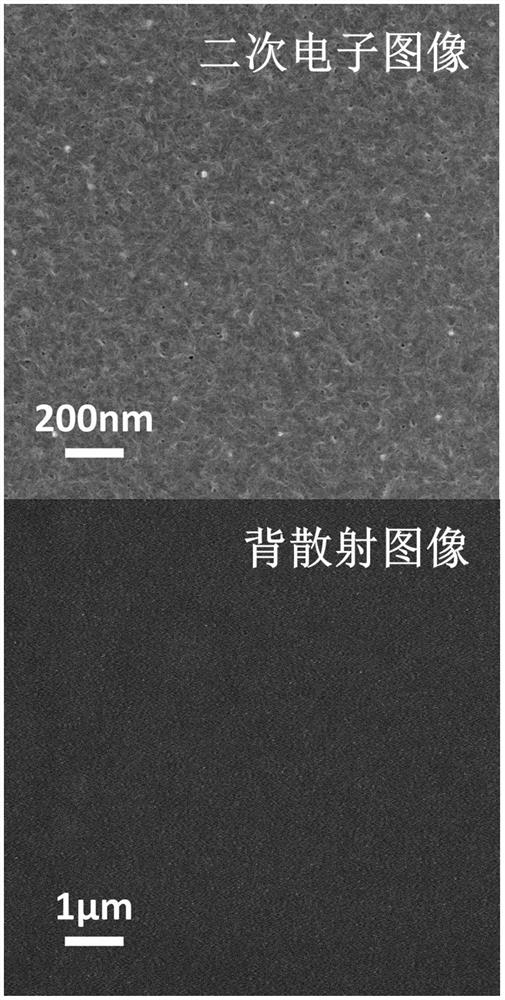

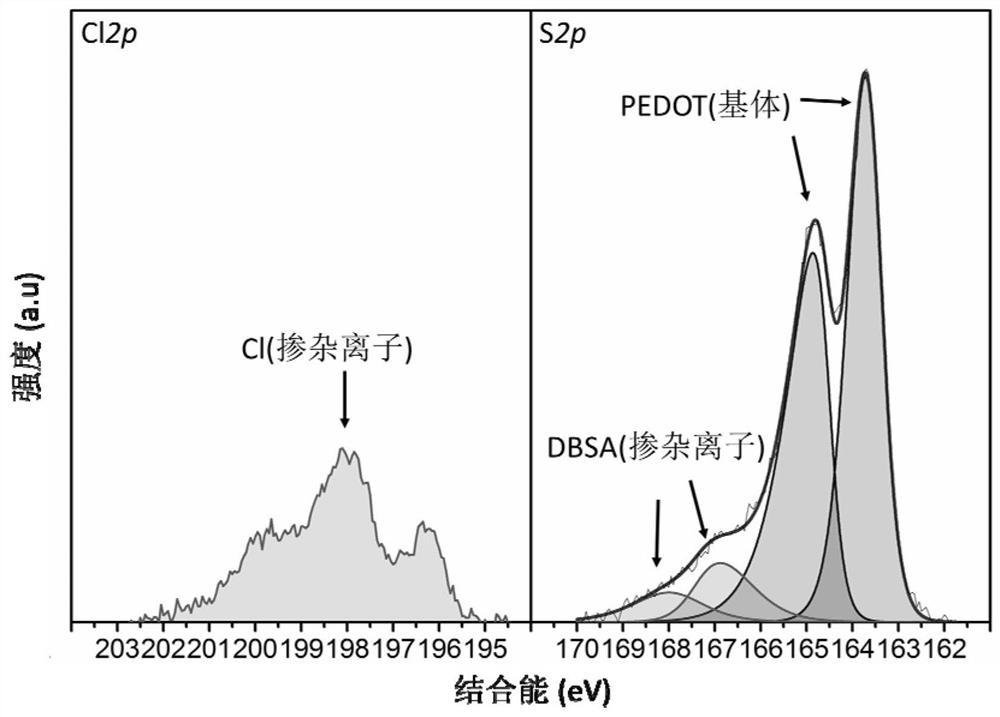

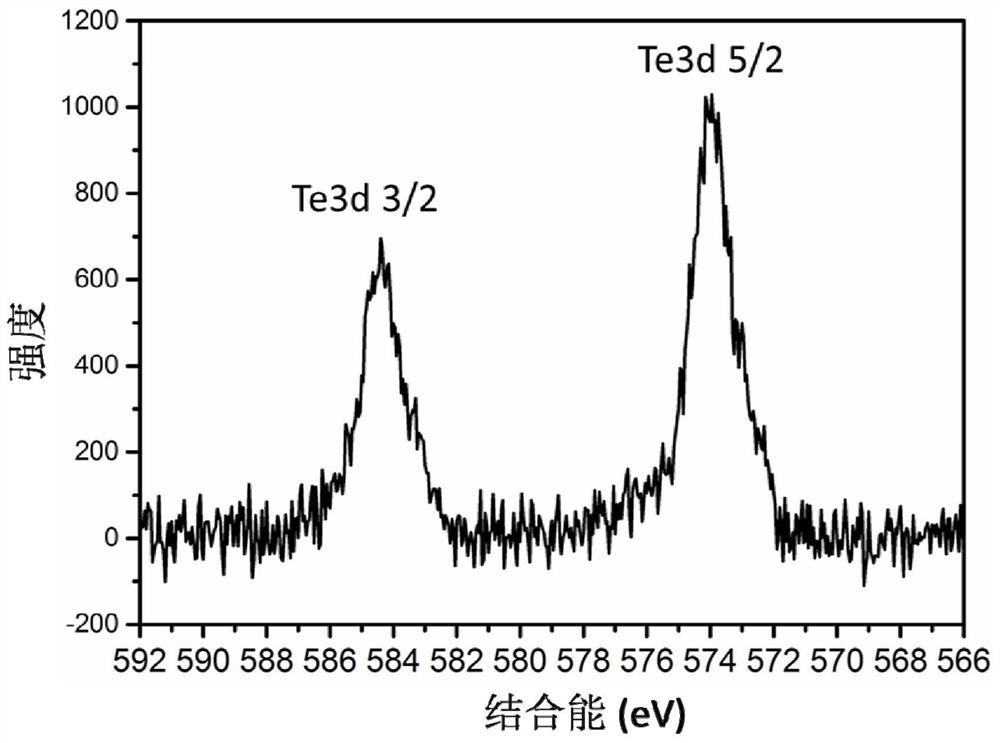

[0048] The invention relates to a high-performance PEDOT-tellurium nanoparticle composite film and a preparation method thereof. The high-performance PEDOT film is prepared by using a gas-phase method by using tellurium tetrahalide and a highly alcohol-soluble iron salt containing weakly basic anions as an oxidant for the reaction. Specifically, including the synthesis of mixed oxidants FeY 3 / TeX 4 , Preparation of precursor solution, spin coating, polymerization, etc., and pickling, water washing, etc. after polymerization. Tellurium tetrachloride has the dual functions of oxidant and tellurium nanoparticle precursor. While oxidizing EDOT monomer to polymerize it, it is reduced to tellurium nanoparticles by itself. The whole process only needs one reaction step; secondly, because the iron salt oxidant has high Alcohol-soluble, PEDOT film with micron film thickness can be obtained, and the weakly basic anion in the iron salt oxidant can control the concentration of hydrogen ...

Embodiment 1

[0064] PEDOT:Cl / dodecylbenzenesulfonic acid-tellurium quantum dots (PEDOT:Cl / DBSA-2~5nmTe) material

[0065] Heat the deionized aqueous solution in which 6.6028 g of sodium dodecylbenzenesulfonate is dissolved to 80°C, and add excess ferric chloride aqueous solution under vigorous stirring until the precipitation of iron dodecylbenzenesulfonate stops. The precipitate was washed ten times with deionized water until no chlorine samples were detected. Then dissolve it with 250mL of ethanol, evaporate to dryness in a rotary evaporator, and transfer it to a glove box. Mix 0.0202g of tellurium tetrachloride (molar ratio Fe:Te=80:1) into the dried product, and then redissolve the mixture in Water ethanol, formulated to a mass fraction of about 79.5% FeDBSA 3 +0.3%TeCl 4 The spin-coating fluid is ready for use. The above solution was spin-coated on a 18*18mm soda-lime glass substrate to form a film at a rotation speed of 5750rpm and a spin-coating time of 15s. Place the spin-coate...

Embodiment 2

[0068] PEDOT:Cl / dodecylbenzenesulfonic acid-tellurium quantum dots (PEDOT:Cl / DBSA-5~20nmTe) material

[0069] Heat the deionized aqueous solution in which 6.6028 g of sodium dodecylbenzenesulfonate is dissolved to 80°C, and add excess ferric chloride aqueous solution under vigorous stirring until the precipitation of iron dodecylbenzenesulfonate stops. The precipitate was washed ten times with deionized water until no chlorine samples were detected. Then it was dissolved in 250 mL of ethanol, evaporated to dryness in a rotary evaporator, and then transferred to a glove box. Mix 0.0606g of tellurium tetrachloride (molar ratio Fe:Te=26.7:1) into the dry matter, then redissolve the mixture in absolute ethanol to prepare about 79.1% FeDBSA 3 +0.8TeCl 4 The spin-coating liquid of % mass fraction is standby. The above solution was spin-coated on a 18*18mm soda-lime glass substrate to form a film at a rotation speed of 6000rpm and a spin-coating time of 18s. Place the spin-coated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com