Efficient high-quality chemical mechanical polishing liquid of yttrium aluminum garnet crystal

A yttrium aluminum garnet, chemical-mechanical technology, applied in polishing compositions containing abrasives, etc., can solve the problems of high waste liquid treatment cost, sub-surface damage of micro scratches, high cost, etc., and achieve scratches and sub-surface. Reduced defects such as damage, reduced crystal surface roughness, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

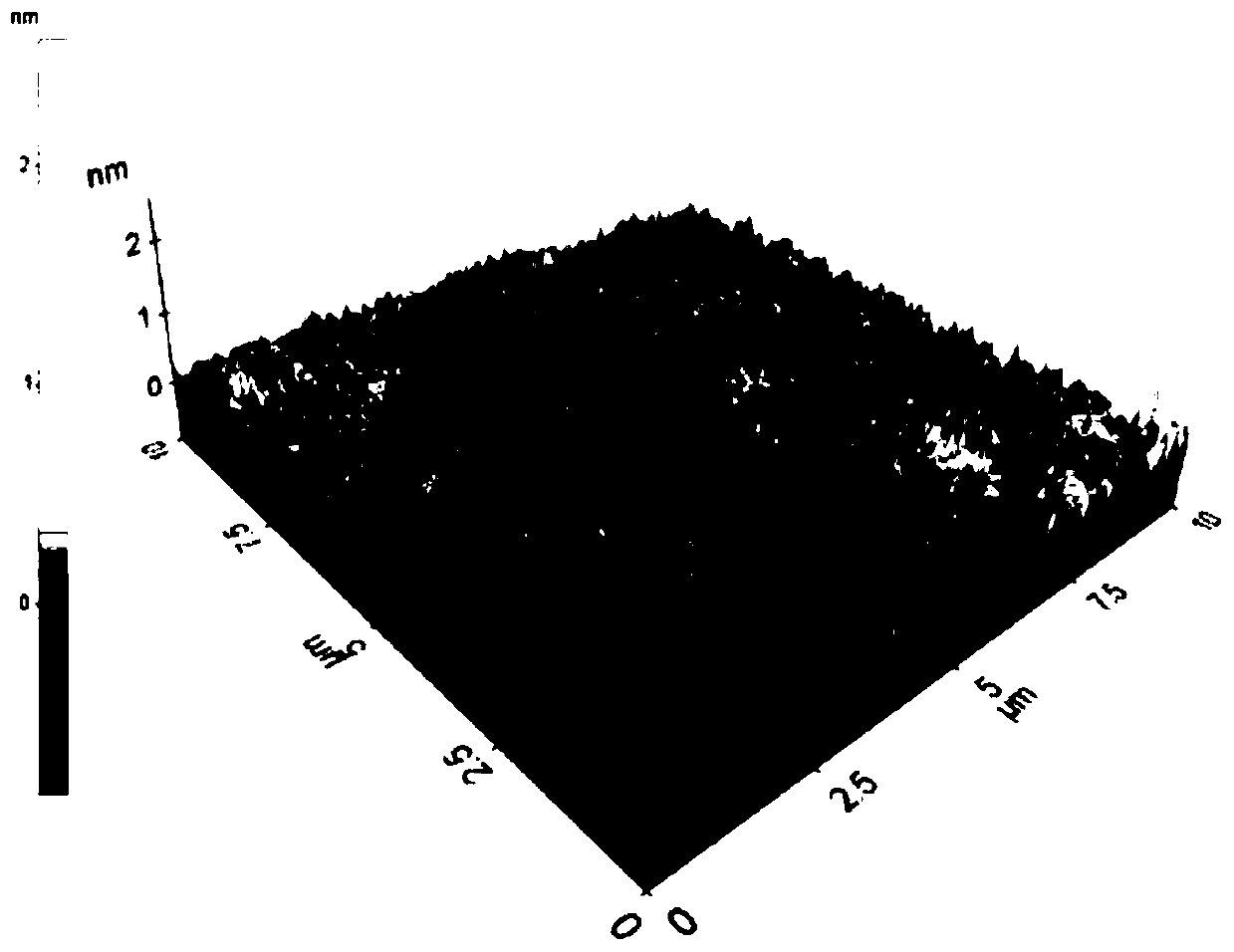

[0018] The purpose of the present invention is to improve the surface quality of yttrium aluminum garnet crystals after polishing and the removal rate of chemical mechanical polishing materials, explore the influence of different components on the polishing effect, and then optimize the ratio of different components in the polishing liquid to finally obtain a polishing solution with excellent performance. Chemical mechanical polishing fluid. Specifically include the following steps:

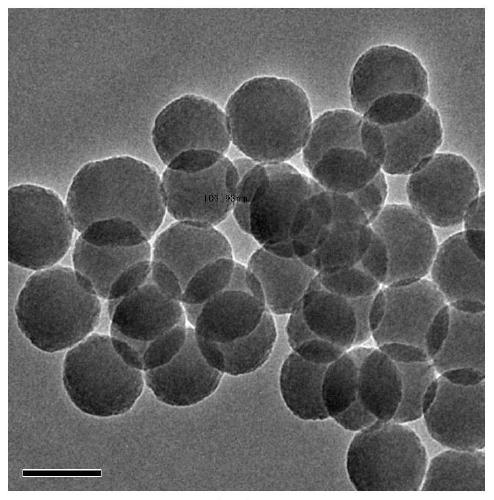

[0019] 1) It is determined that zirconia with a particle size of 80nm is selected as the polishing liquid abrasive, and its dispersed particle size in the solution is as follows: figure 1 shown. Sodium silicate and magnesium oxide are used as chemical reaction reagents, and the concentrations are 0.05g / ml and 3g / L respectively.

[0020] 2) Prepare an aqueous solution containing 8% zirconia as polishing liquid 1 and a mixed aqueous solution containing 8% zirconia and 5% sodium silicate as polish...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap