Insulation shielding composite film capable of storing heat and having high safety

A technology of insulation shielding and composite film, applied in the direction of film/sheet adhesive, non-polymer adhesive additive, adhesive additive, etc., which can solve the problem of interfering with the normal operation of electronic modules, reducing working performance and shortening working life and other problems, to achieve good shielding and heat storage functions, prolong service life, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

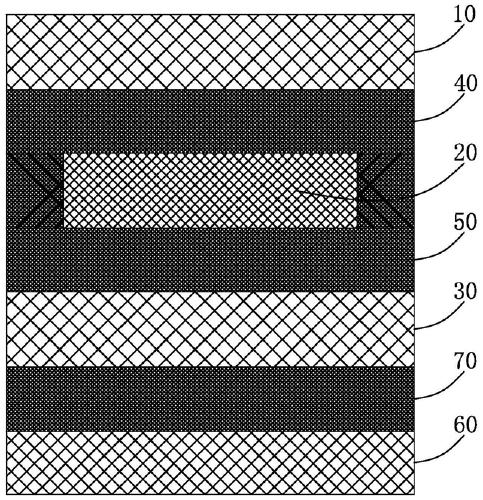

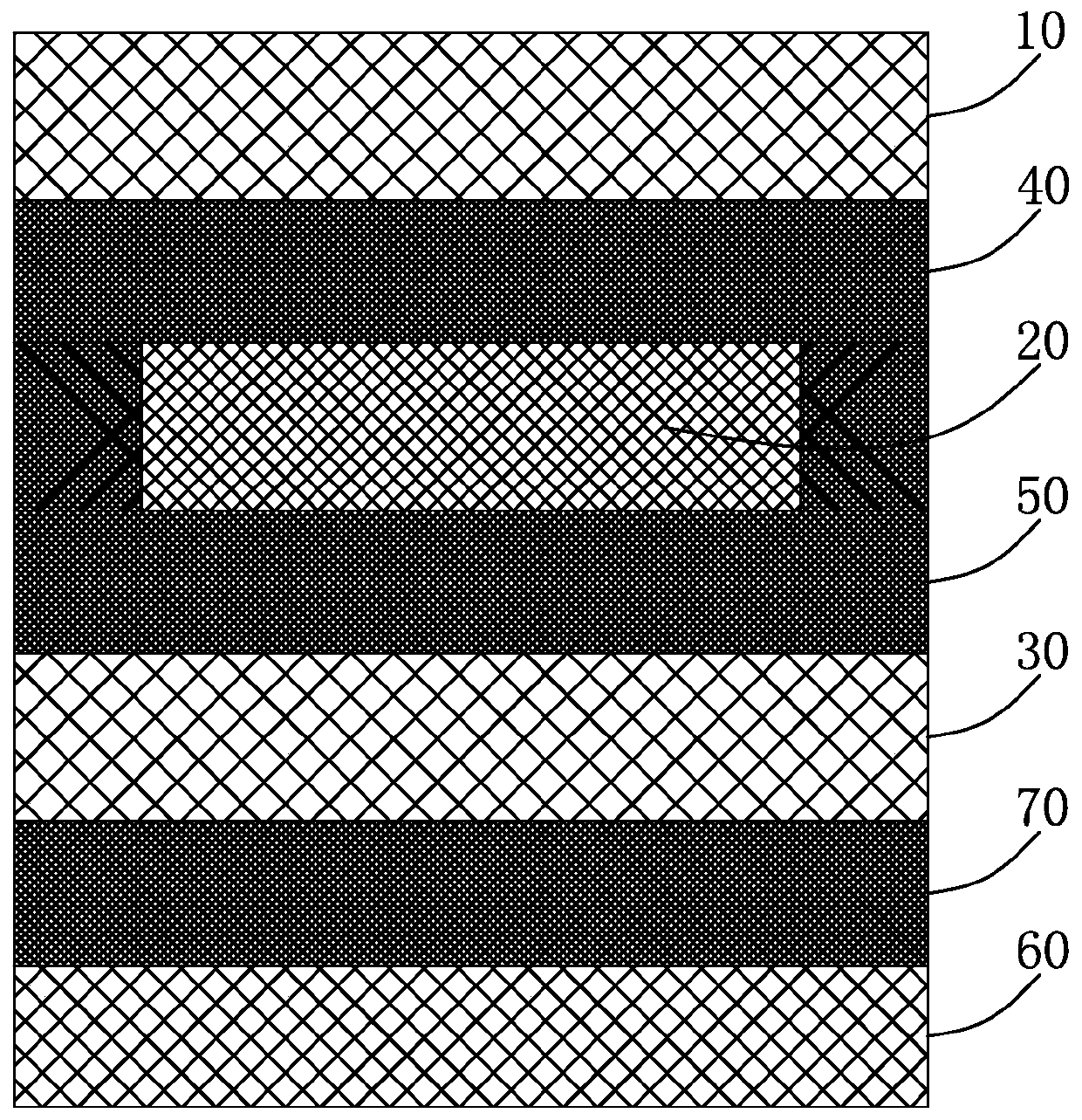

[0021] refer to figure 1 , The insulating and shielding composite film capable of heat storage and high safety of the present invention is composed of a thermally conductive and insulating polyimide film, a nano energy storage graphite sheet, a thermally conductive adhesive layer and a release film. From top to bottom, it includes an upper heat-conducting and insulating polyimide film 10, an upper heat-conducting adhesive layer 40, a nano-energy storage graphite sheet 20, a middle heat-conducting adhesive layer 50, a lower heat-conducting and insulating polyimide film 30, and a lower heat-conducting adhesive layer. 70 and release film 60. The composite film is used as a heat dissipation device for chips or electronic modules in electronic equipment.

[0022] like figure 1 As shown, the upper heat-conducting and insulating polyimide film 10 has excellent heat-conducting properties and strong insulating properties. The thickness of the upper heat-conducting and insulating pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com