A fixture device

A jig device and jig technology, applied in metal material coating process, vacuum evaporation coating, coating, etc., can solve the problem of reducing the effective film forming area of vapor deposition equipment, increasing the area of the opaque area of the floating mask, Fixtures are prone to problems such as film coating problems, achieving the effects of simple disassembly, improved production efficiency, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

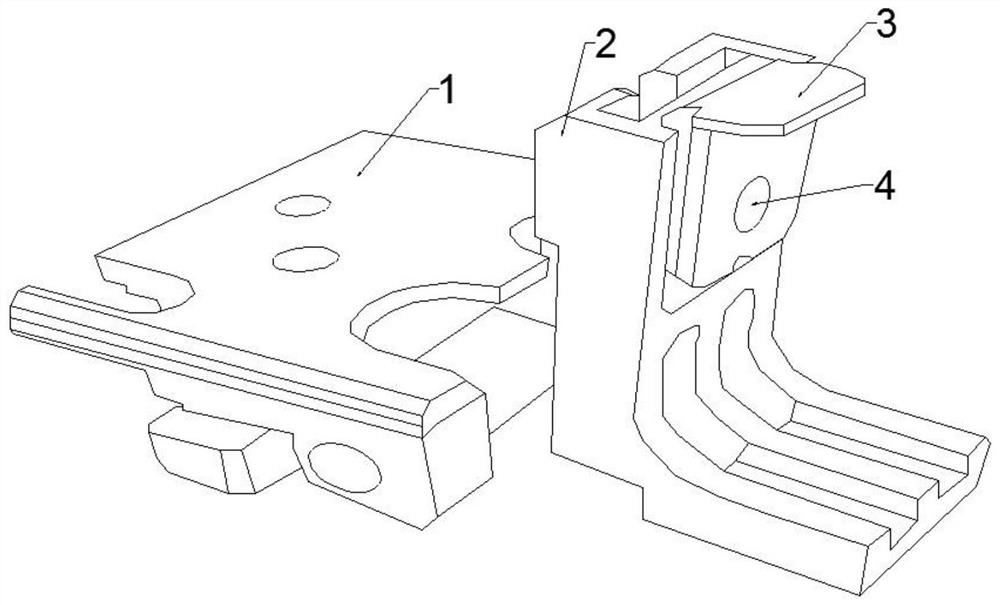

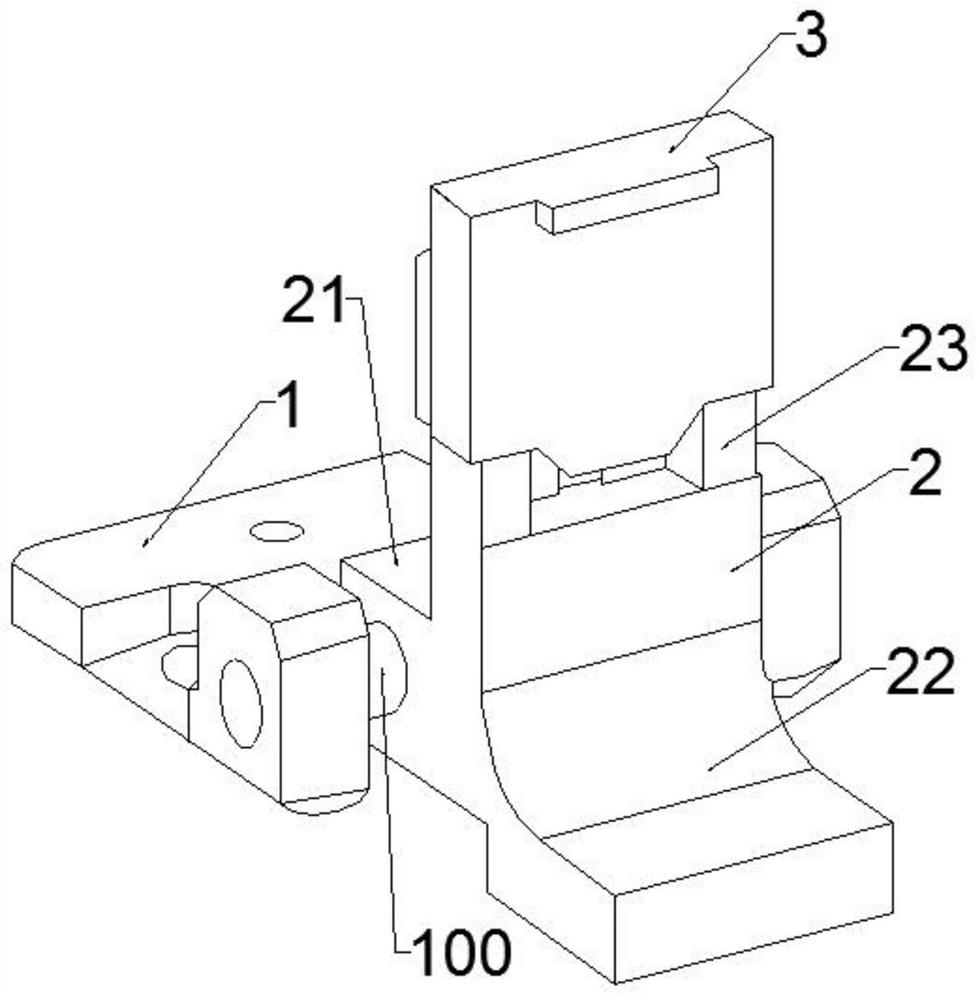

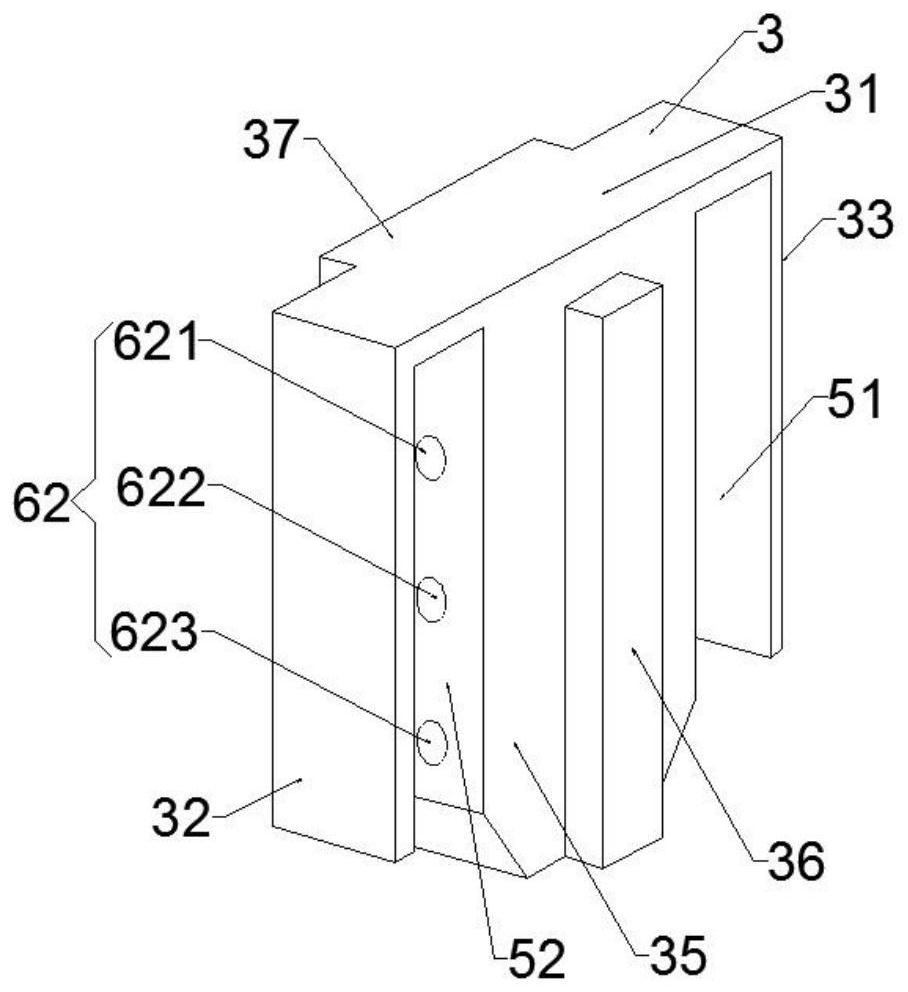

[0029] Such as Figure 2 to Figure 4 Shown is a schematic structural view of an embodiment of the fixture device of the present invention. This embodiment provides a fixture device, including: a base 1 connected to a substrate support tray (not shown in the figure), a support part 2 connected to the base 1 and The clamp 3 is set on the upper end of the support part 2. The support part 2 includes a first connecting body 21 at one end, a second supporting body 22 extending in the opposite direction to the first connecting body 21, and a third connecting body 23 at the other end. A connecting shaft 100 passes through the first connecting body 22. A connecting body 21 is fixedly connected to the base 1; the second supporting body 22 and the third connecting body 23 are L-shaped, and the second supporting body 22 is used to support the substrate; the clamp 3 is set on the end of the third connecting body 23 part, and the clamp 3 covers the top of the third connecting body 23, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com