A multi-chamber energy-saving aluminum electrolytic cell capable of continuous operation

An aluminum electrolytic cell and electrolytic cell technology, applied in the field of aluminum electrolytic cells, can solve the problems of low energy saving and environmental protection, and achieve the effects of easy maintenance and replacement, lower cell voltage, and reduced space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

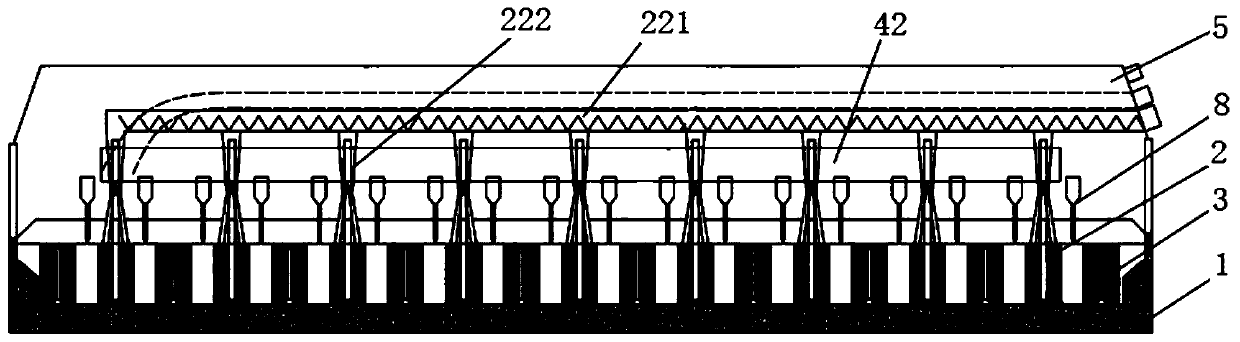

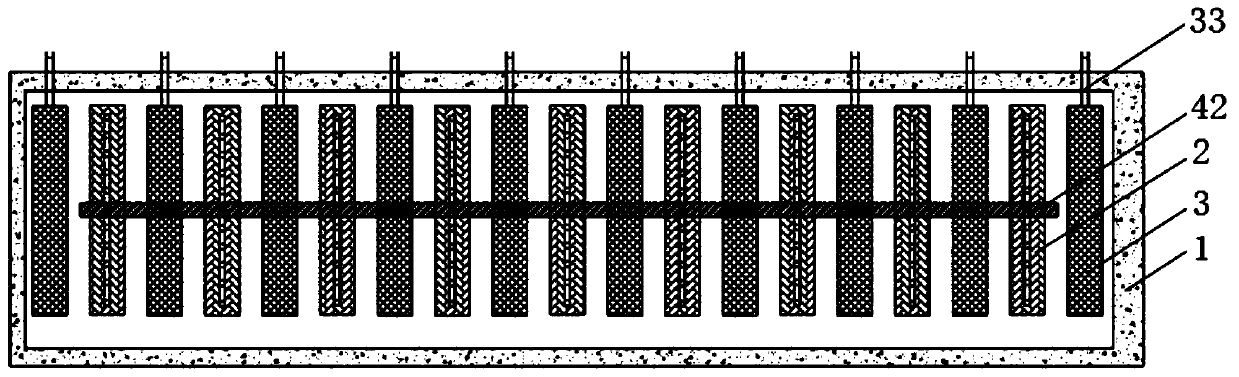

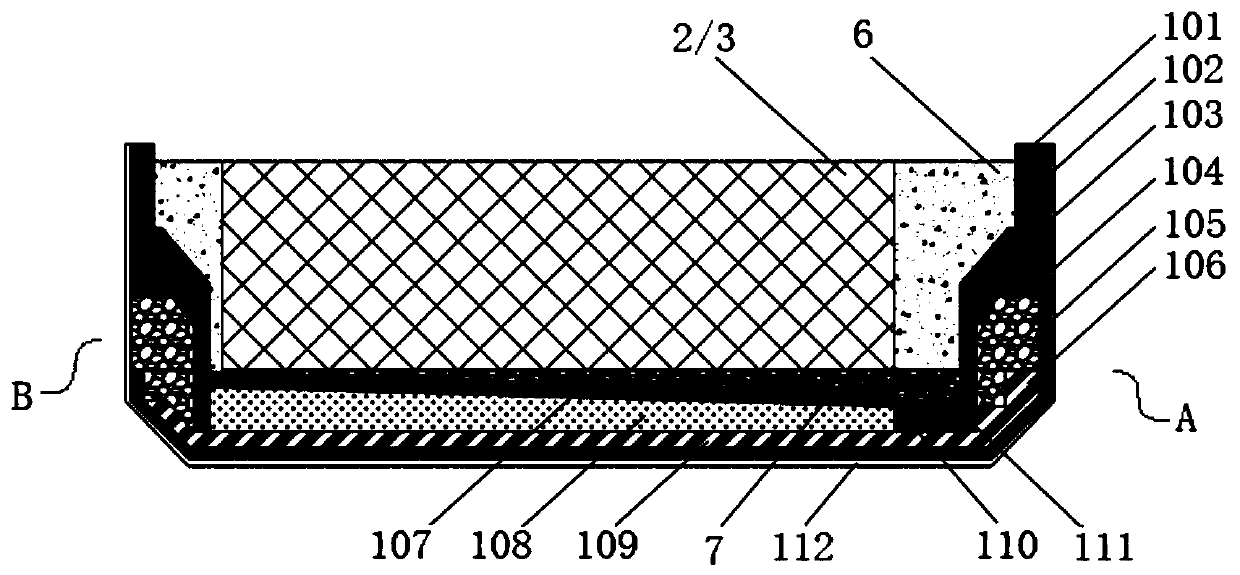

[0066] see figure 1 and figure 2 , the multi-chamber aluminum electrolytic cell in the illustration is a specific embodiment of the present invention, specifically including a cell body 1, an anode 2, a cathode 3, a bus system, an electrolytic cell superstructure 5 and an alumina blanking system 8. In this embodiment The capacity of the electrolytic cell is 400kA. There are 10 sets of cathodes 3 and 9 sets of anodes 2. The anodes 2 and cathodes 3 are arranged alternately inside the cell 1 along the horizontal direction of the bottom of the cell. The anodes 2 and cathodes 3 are plate electrodes of the same size. structure, adjacent anodes 2 and cathodes 3 are arranged vertically and form parallel electrolysis chambers, all anodes and cathodes have electrolysis areas of the same size, and 18 cells are formed in the cell body 1 of the entire electrolytic cell along the horizontal direction Such an electrolytic chamber. The bottom surface of the cell body 1 of the electrolytic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com