Multi-layer yarn leasing machine

A technology of splitting machine and yarn, applied in the direction of splitting, other manufacturing equipment/tools, textiles and papermaking, etc., can solve the problems of not having different types, completing the splitting alternately, and not being able to freely choose the number of splitting layers, etc. To achieve the effect of improving the working efficiency of the equipment and ensuring the effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

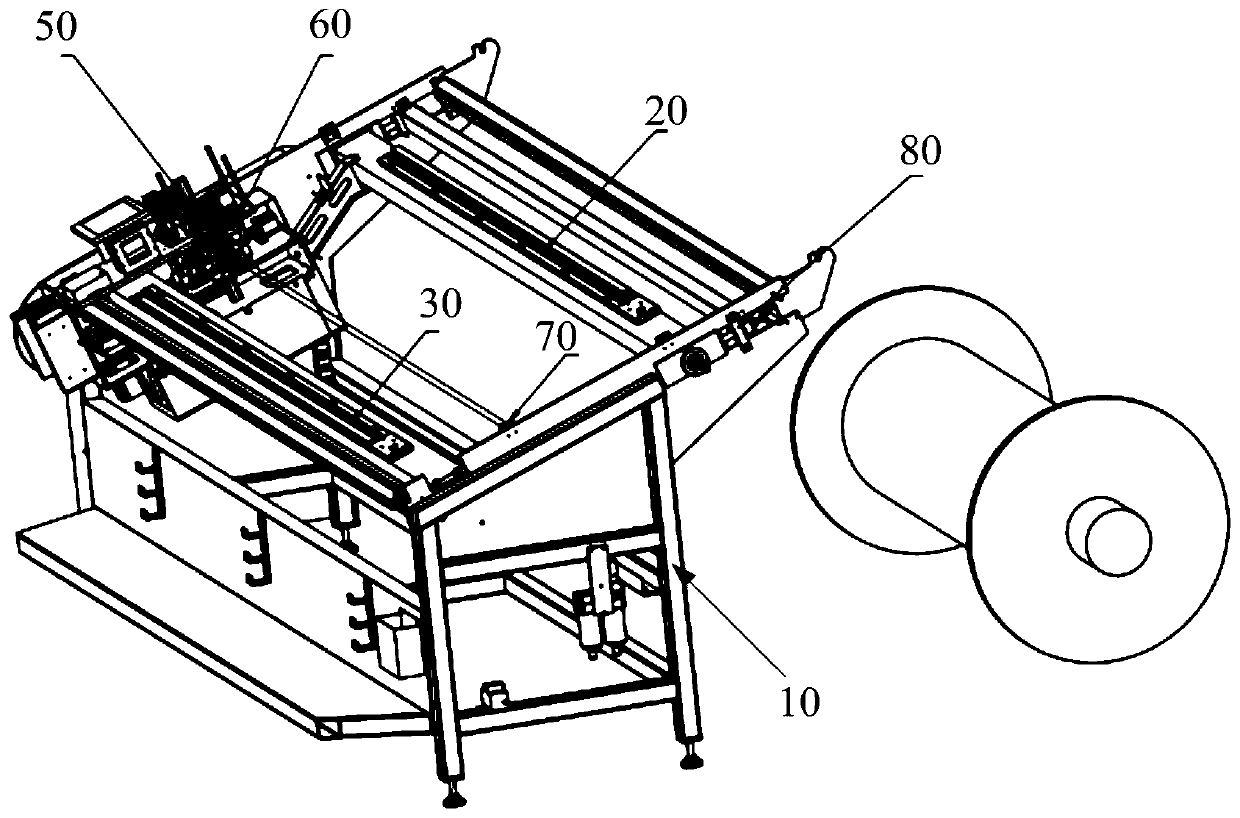

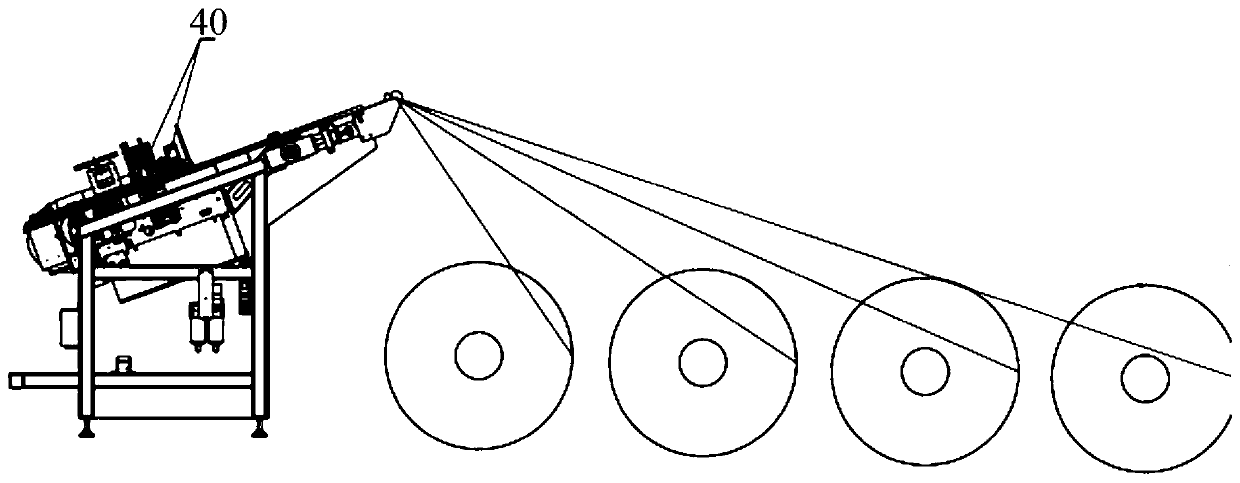

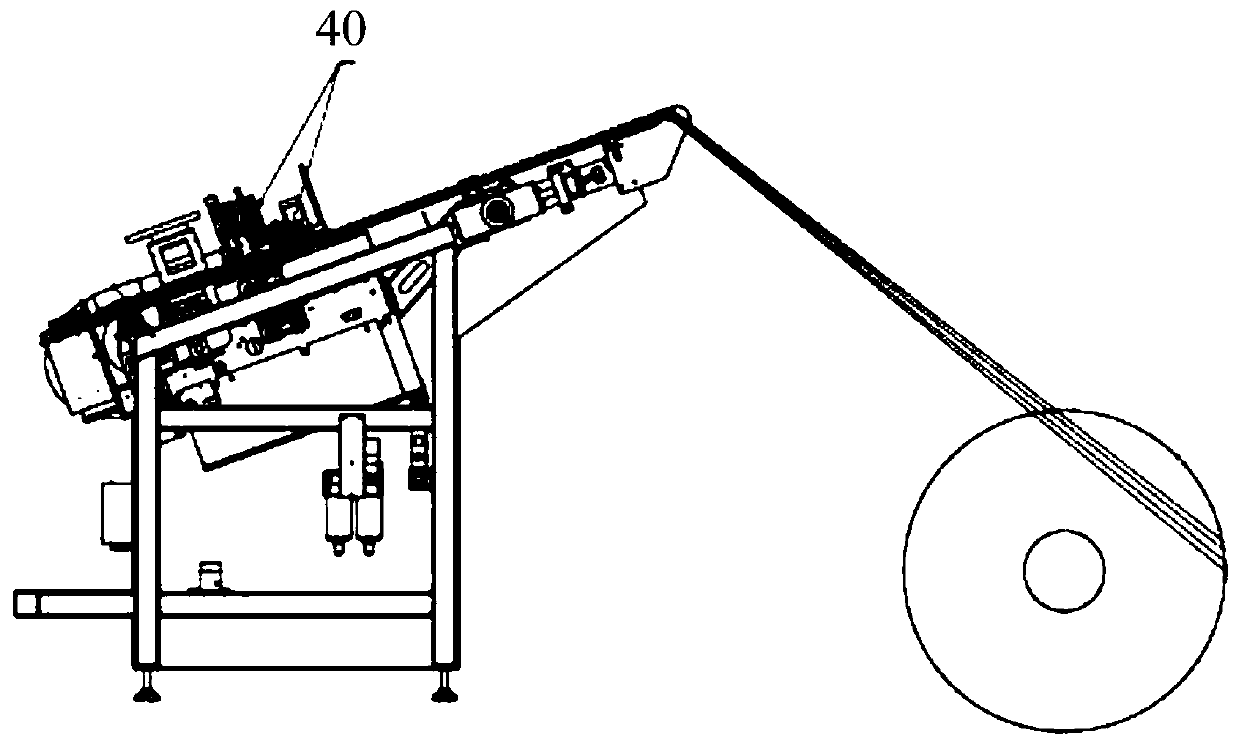

[0029] Considering that the current splitting machine cannot choose the number of splitting layers freely, it is not possible to allow multiple yarns to be merged into the same layer in an orderly manner according to the textile pattern and to complete the splitting alternately. It is not possible to achieve weaving by a splitting machine. A piece of cloth can have different types of yarns or colors, and the work efficiency is low. Therefore, the present invention provides a multi-layer yarn splitting machine, which realizes the function of simultaneously splitting multiple pans on a splitting machine , The multi-layer yarns of multiple weaving shafts or the multi-layer yarns of a single weaving shaft are simultaneously split, so that the multi-layer yarns are combined into the same layer in an orderly manner accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com