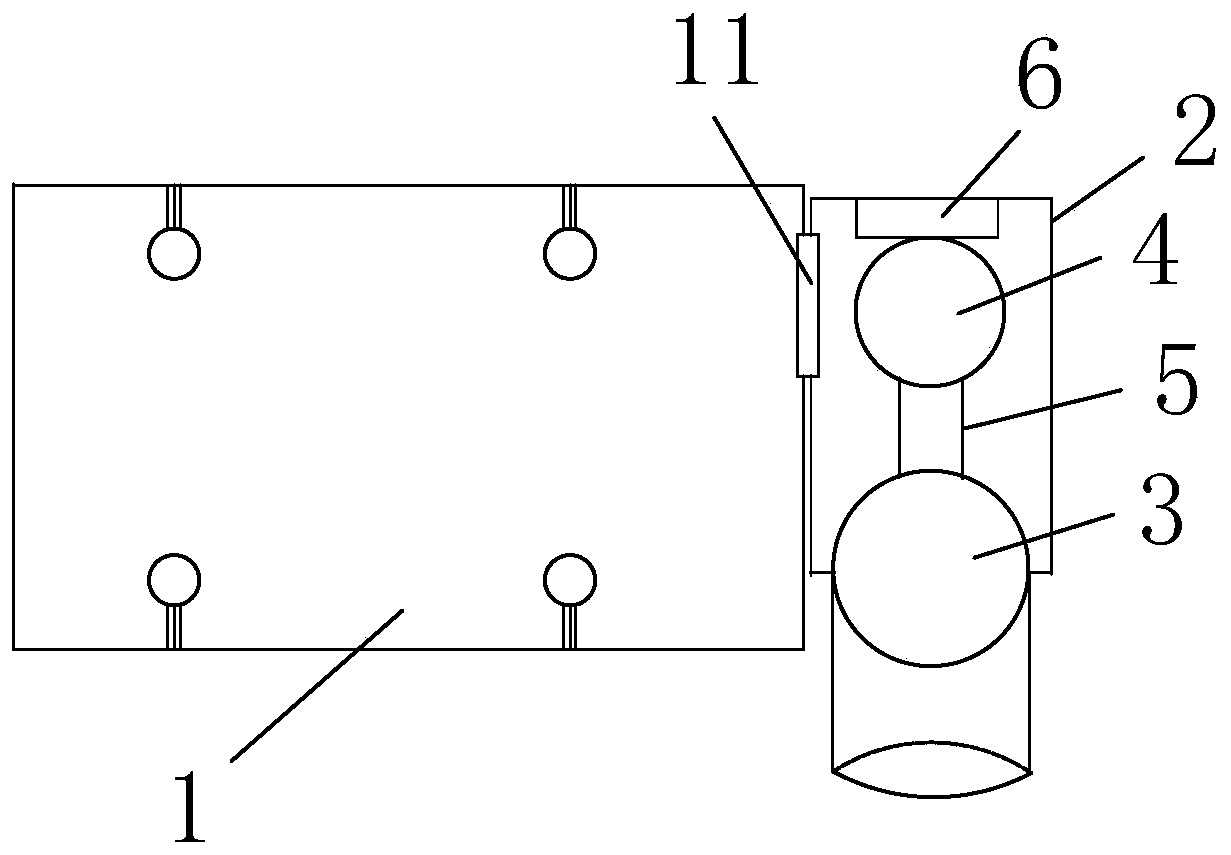

Life cabin escape system

An escape system and life technology, applied in the field of escape systems, can solve problems such as slow descending speed, and achieve the effects of reducing power consumption, increasing length, and increasing escape speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

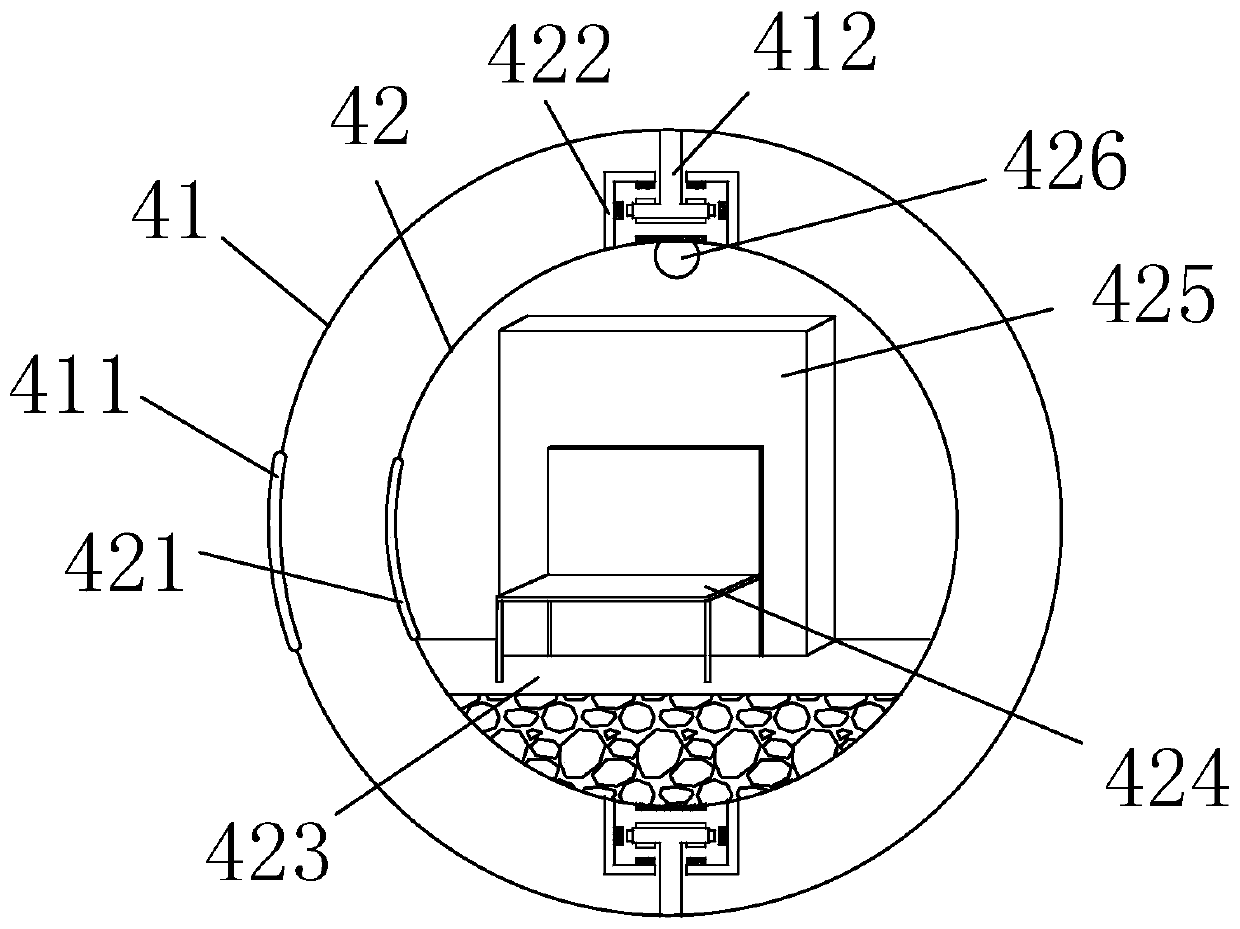

[0029] Such as Figure 4 As shown, the escape passage in this embodiment is vertical; the vertical escape passage has the fastest escape speed, but in order to ensure the safety of the personnel in the escape cabin during the escape process, a safety valve is provided at the bottom of the vertical part of the escape passage. Air cushion; And present embodiment is not suitable for high-floor escape use.

Embodiment 2

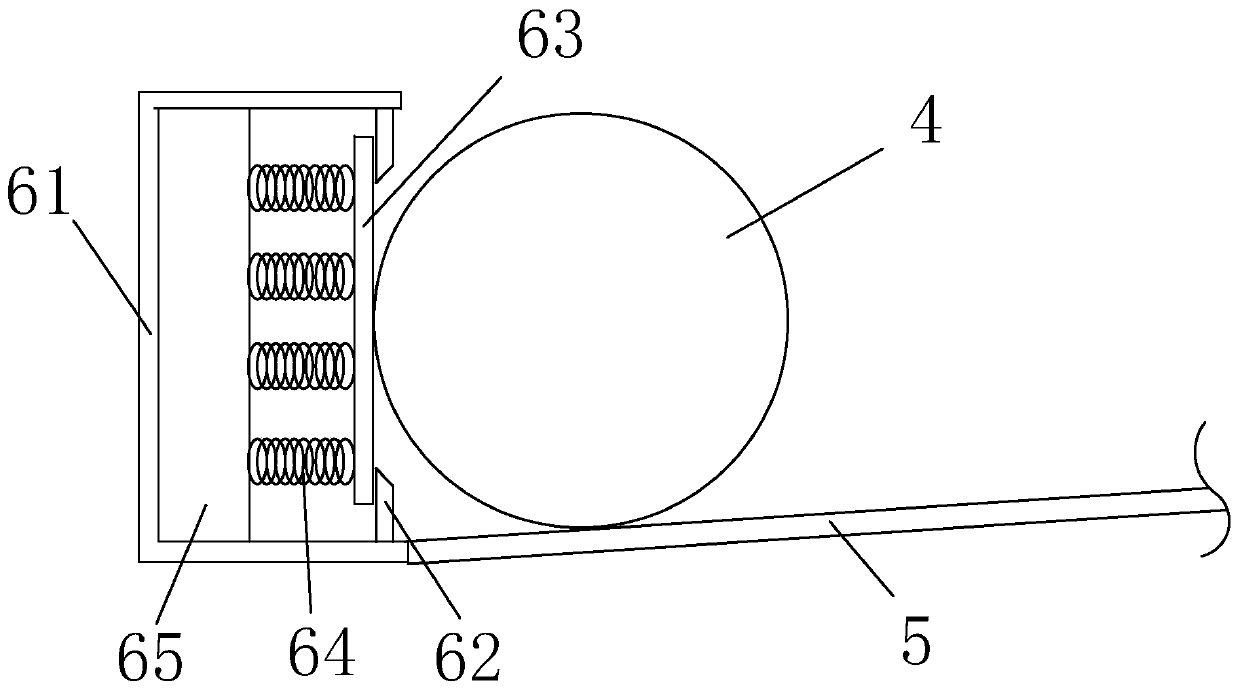

[0031] Such as Figure 5As shown, the escape passage in this embodiment is inclined; compared with Embodiment 1, the safety of this embodiment is higher, and in order to further enhance the safety of this embodiment, a silica gel pad can be laid in the escape passage to prevent escape The outer surface of the cabin is provided with a thin layer of rubber to increase the friction of the escape cabin when it rolls, thereby reducing the speed of the escape cabin and enhancing safety; it can also extend the length of the escape passage, reduce the slope of the escape passage, and increase the slowness to ensure escape. It is safe and can directly transport escaped people to an open place far away from danger.

Embodiment 3

[0033] Such as Figure 6 As shown, the escape passage in the present embodiment is spiral, and the present embodiment is safer than the first embodiment, and saves more floor space than the second embodiment; the spiral escape passage can effectively slow down the falling speed of the escape cabin. To further enhance safety, silica gel pads can be laid in the escape passage, and a thin rubber layer is provided on the outer surface of the escape cabin to increase the friction force when the escape cabin rolls, reduce the speed of the escape cabin, and enhance safety.

[0034] Compared with the prior art, the present invention has the following advantages:

[0035] a. The spherical escape cabin can move quickly without professional training, and can accommodate many people at the same time, increasing the escape speed;

[0036] b. There is storage space for food and drinking water in the escape cabin, which can ensure that the escaped personnel have sufficient food sources afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com