Microobjective numerical aperture measurement method based on diffraction grating

A technology of microscopic objective lens and numerical aperture, which is applied in the field of optical detection, and can solve problems such as large errors in measurement results, cumbersome operation, and single measurement standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

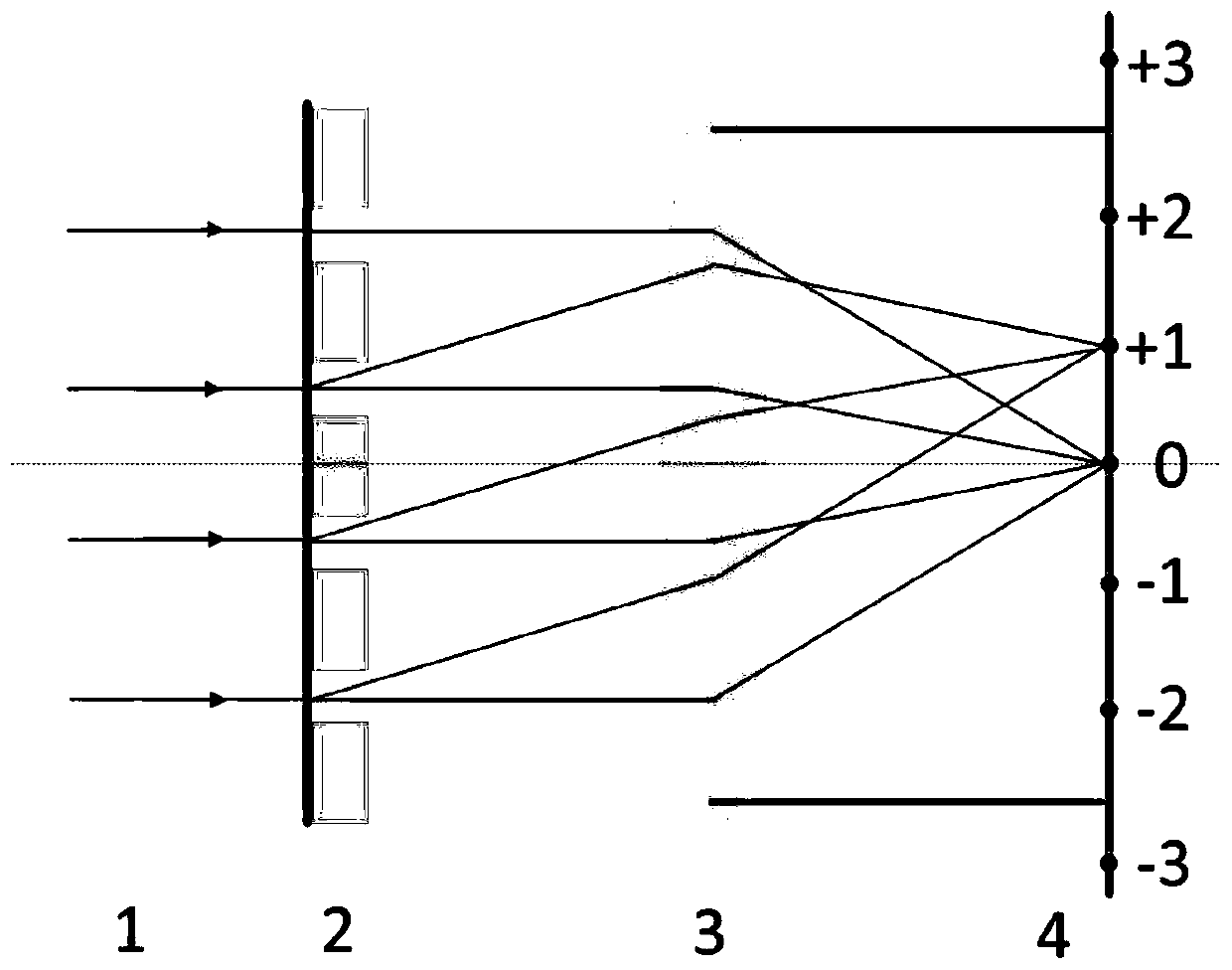

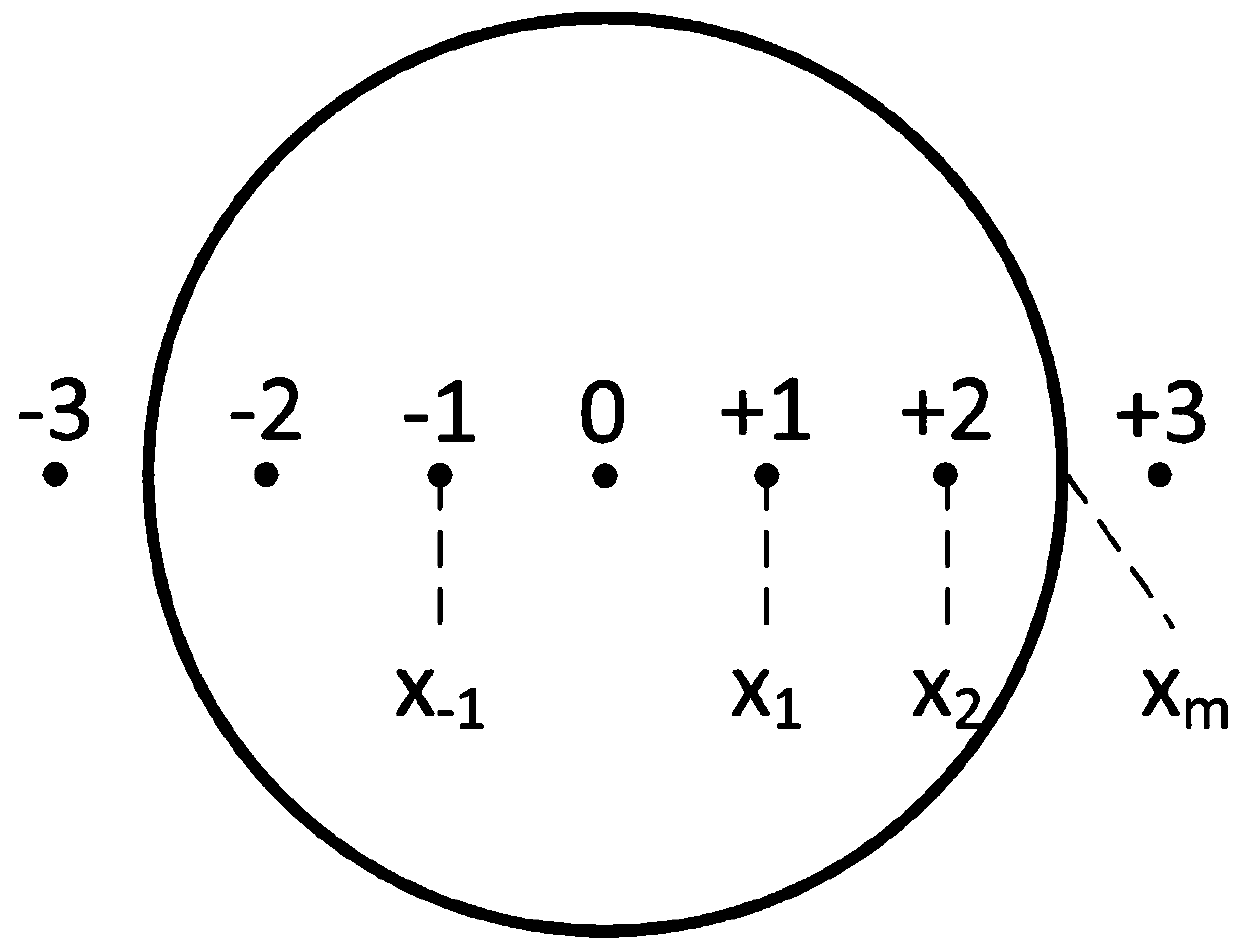

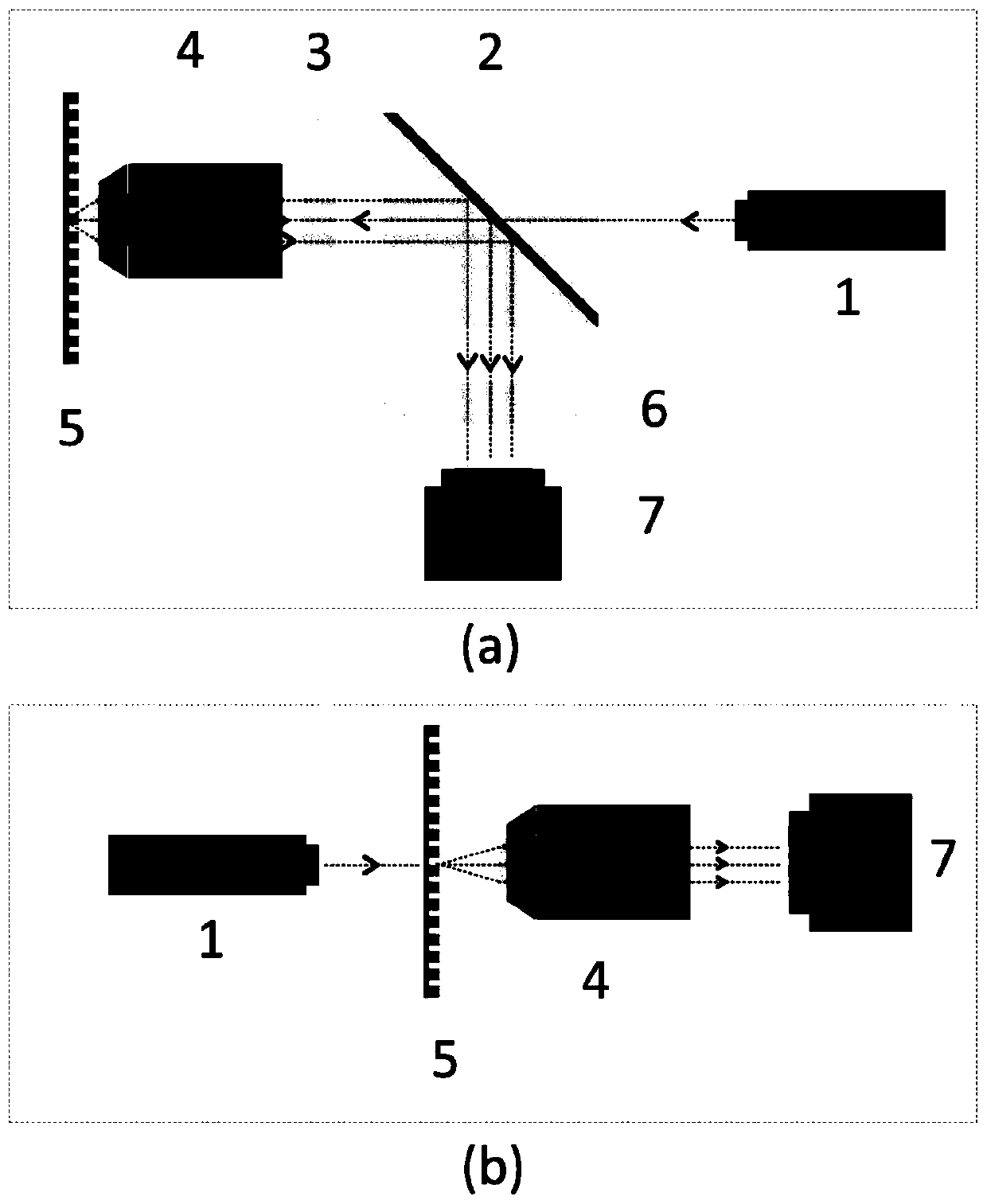

[0026] Specific Embodiment 1: Combining image 3 The optical path in (a) illustrates the present embodiment, and now the diffraction grating (5) is a reflective grating, and a kind of microscopic objective lens numerical aperture method based on the diffraction grating described in the present embodiment, the purpose is to pass the diffraction effect and display The imaging effect of the micro-objective lens obtains the numerical aperture of the micro-objective lens to be tested, and it comprises: collimated illumination light source (1); Beamsplitter prism (2); Lens 1 (3); Microscopic objective lens to be measured (4); Diffraction grating ( 5); lens 2 (6); image sensor (7). The collimated light beam emitted by the collimated illumination source (1) passes through the dichroic prism (2) and the lens 1 (3), and after being converged by the microscopic objective lens (4) to be measured and irradiated on the diffraction grating (5), the diffraction After the light is reflected a...

specific Embodiment approach 2

[0031] Specific Embodiment 2: Combining image 3 The optical path in (b) illustrates the present embodiment, and now the diffraction grating (5) is a transmissive grating, and a kind of method for the numerical aperture of the microscopic objective lens based on the diffraction grating described in the present embodiment, the purpose is to pass the diffraction effect and display The imaging function of the micro-objective lens obtains the numerical aperture of the micro-objective lens to be tested, which includes: a collimated illumination light source (1); a diffraction grating (5); a micro-objective lens to be tested (5); and an image sensor (7). After the collimated light beam emitted by the collimated illumination source (1) is irradiated on the diffraction grating (5), the generated diffracted light passes through the microscopic objective lens (4) to be tested to obtain multi-level diffraction fringes on the image sensor (7), The numerical aperture of the microscopic obj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com