Human factor reliability analysis method for an operator of a digital master control room of a nuclear power station

An analysis method and operator's technique, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as inability to handle behavior, increase the occurrence of accidents, and not comprehensively and properly considered, to reduce errors and be more reasonable. The effect of improving the reliability of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

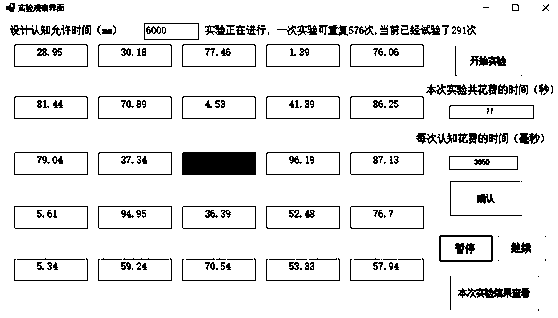

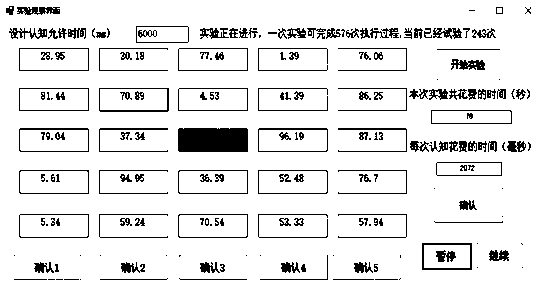

[0047] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

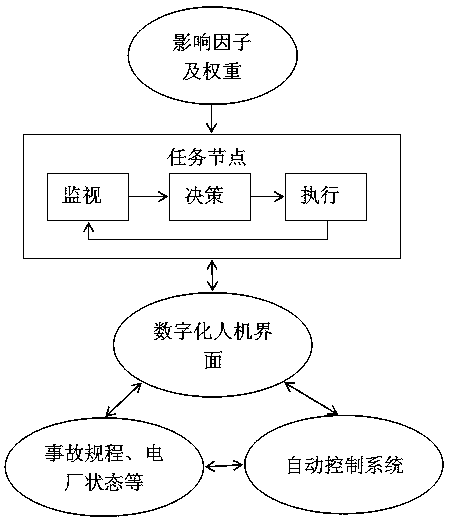

[0048] A human factor reliability analysis method for an operator in a digital main control room of a nuclear power plant includes four steps, and the details of each step are as follows.

[0049] 1. Regarding step 1 "determining that the dynamic cognitive process of the operator in the digital main control room of the nuclear power plant includes three cognitive stages of monitoring, decision-making and execution, the sum of the error rates of the three cognitive stages represents the reliability of human factors. " and Step 2 "Using exponential structure to define the relationship between the error rate of each cognitive stage"

[0050] At present, human reliability analysis has begun to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com