Overturning screwdriving device for lithium battery package

A flip lock and lithium battery technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of laborious and unsafe operations for employees, and achieve the effect of reducing labor intensity and improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

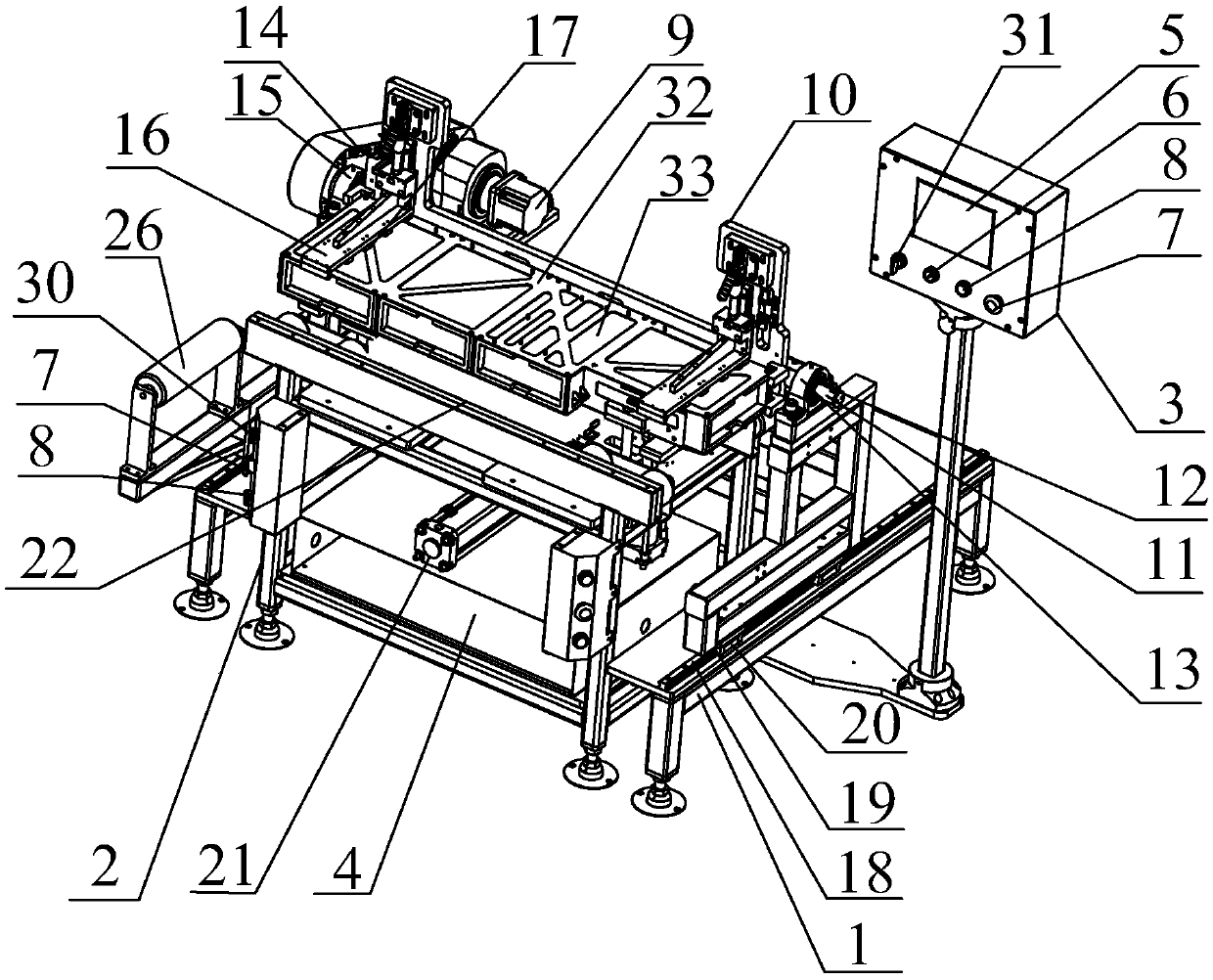

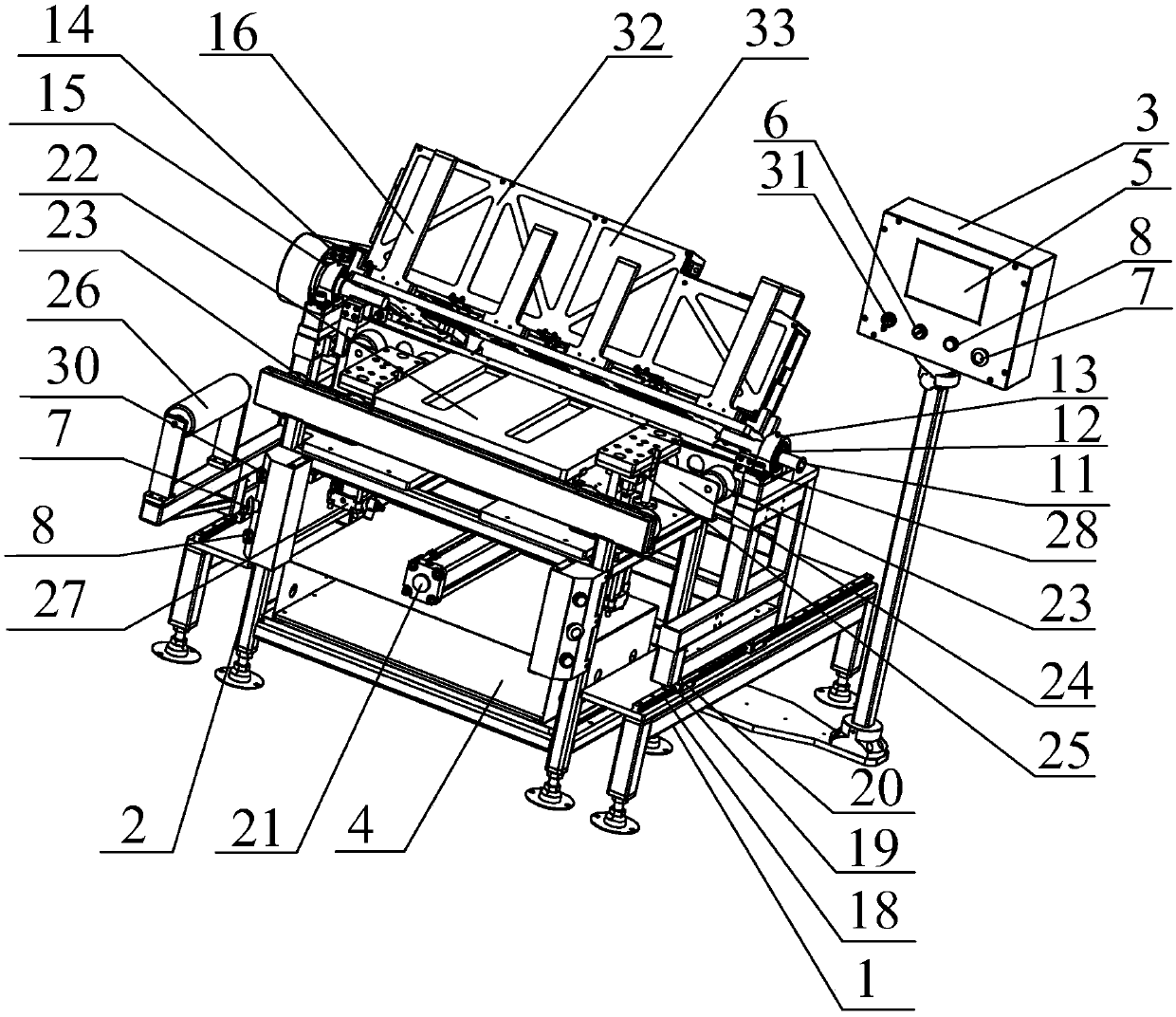

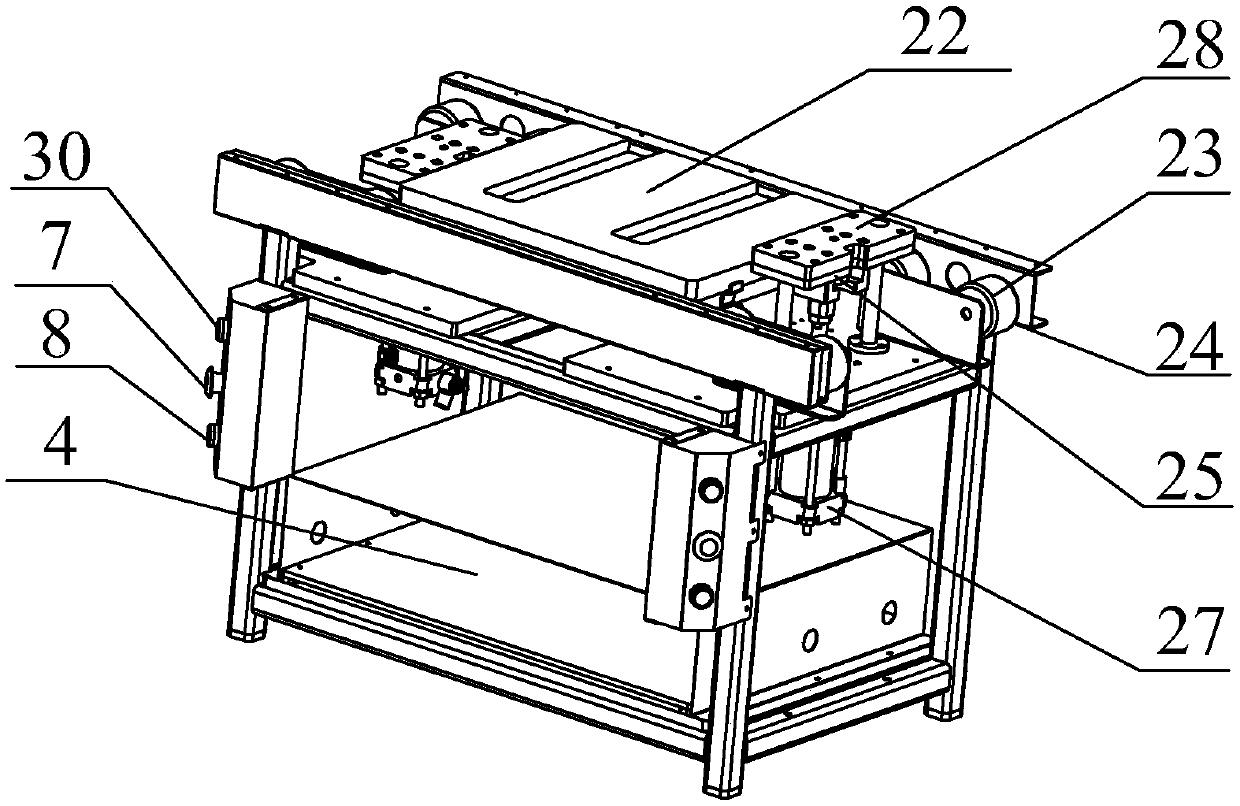

[0025] The technical solutions of the present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings.

[0026] In the present invention, unless otherwise specified, all equipment can be purchased from the market or commonly used in this industry. The methods in the following examples, unless otherwise specified, are conventional methods in this field.

[0027] Such as figure 1 As shown, a lithium battery pack flip lock screw device includes a frame 2 with a base 1, a transmission line mechanism, a flip mechanism and a control panel 3 that are slidingly connected to the frame base and a control panel 3; the frame base is provided with a distribution box 4. The control panel is electrically connected to the distribution box; the control panel has a touch screen 5, an automatic power switch 6, a manual switch button 31, an emergency stop button 7 and a reset button 8. The turning mechanism includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com