Hot forging combined machine tool

A combined machine tool and hot forging technology, applied in manufacturing tools, other manufacturing equipment/tools, metal processing, etc., can solve the problems of low processing efficiency, achieve the effect of improving work efficiency, improving work efficiency, and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

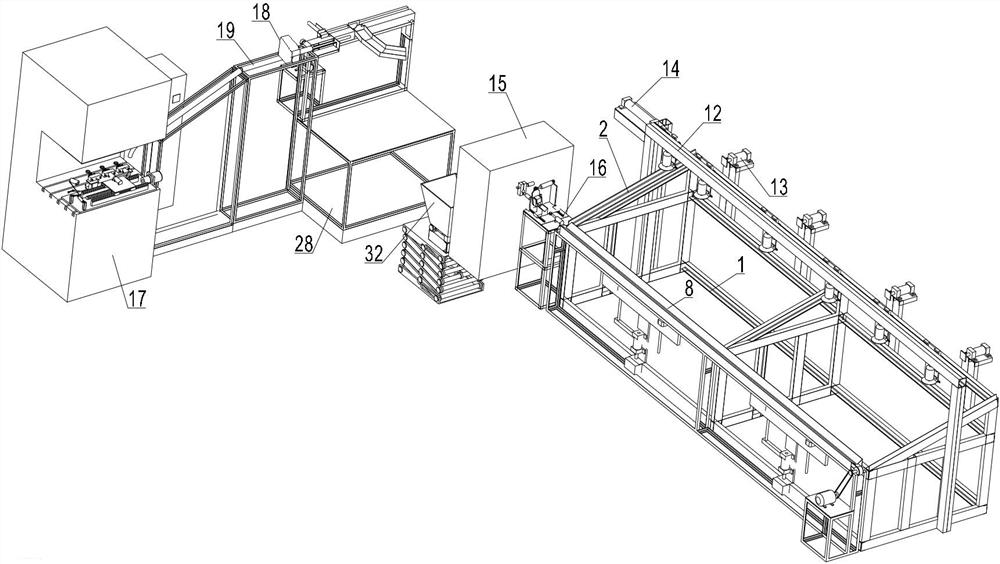

[0032] The invention discloses a hot forging combined machine tool, in particular to a production line for hot forging processing bars. The combined machine tool starts from the blanking of the bar, then the delivery of the bar, and then the heating and hot forging of the bar. The combined machine tool can realize the automatic production of hot forging bar. The machine is also capable of forging nut blanks. The following are specific examples:

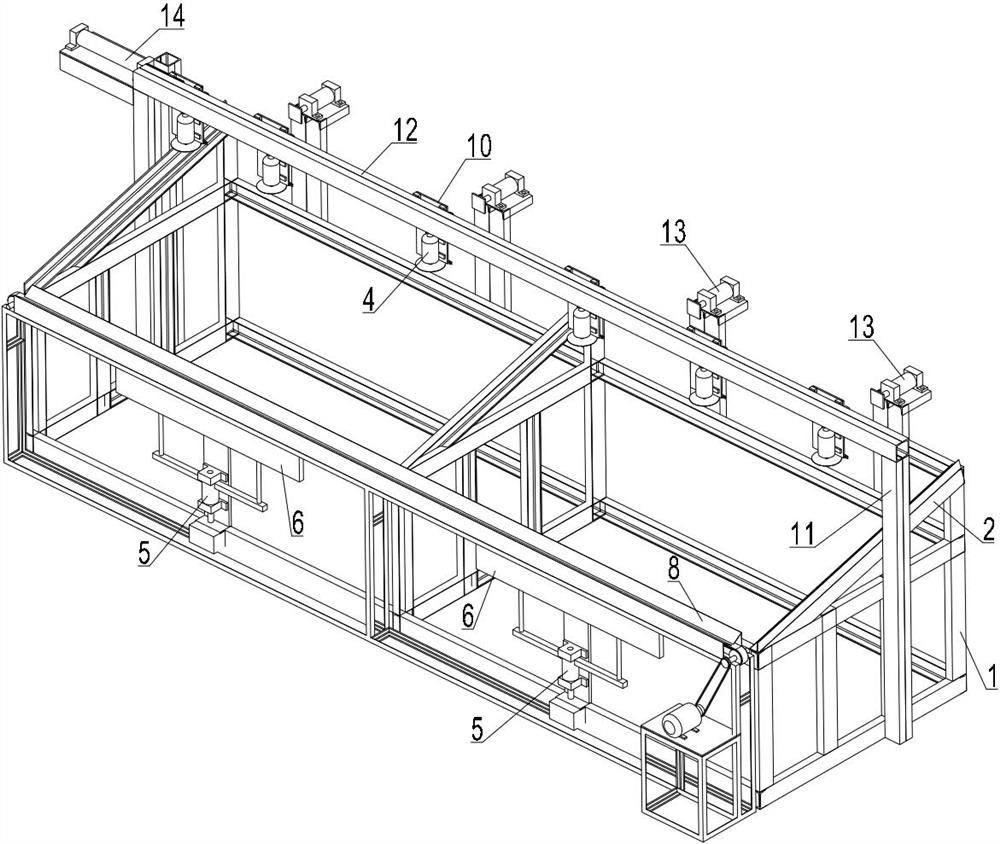

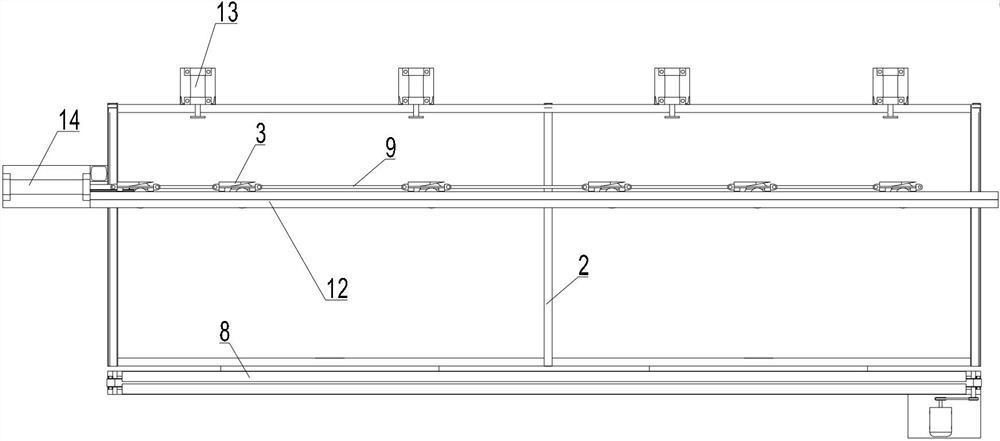

[0033] Such as figure 1 As shown, the first device of the present invention is a bar material unbundling device, which is used to unbundle the whole bundle of bars in the binding device, specifically to cut the binding strips of the whole bundle of bars for unbundling, and at the same time it can The unbundled bars are sorted and sent to the next process. The specific settings are as follows:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com