Water-jet type marine engine

An engine and water-jet technology, which is applied to ships, ship propulsion, ship parts, etc., can solve problems that affect safety, complex manufacturing process, and low efficiency, and achieve the goals of reducing draft, preventing hull tilt, and improving safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

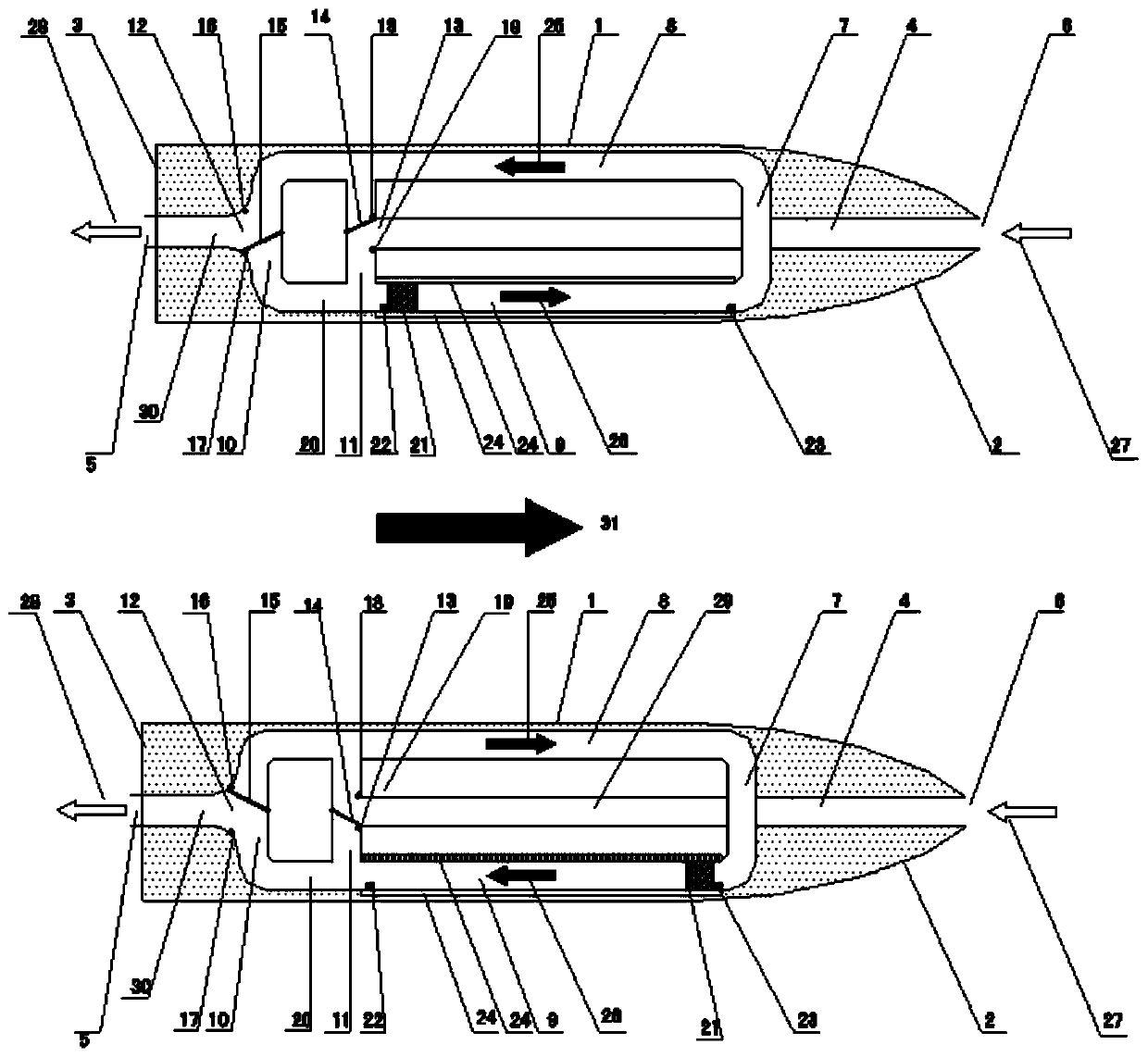

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

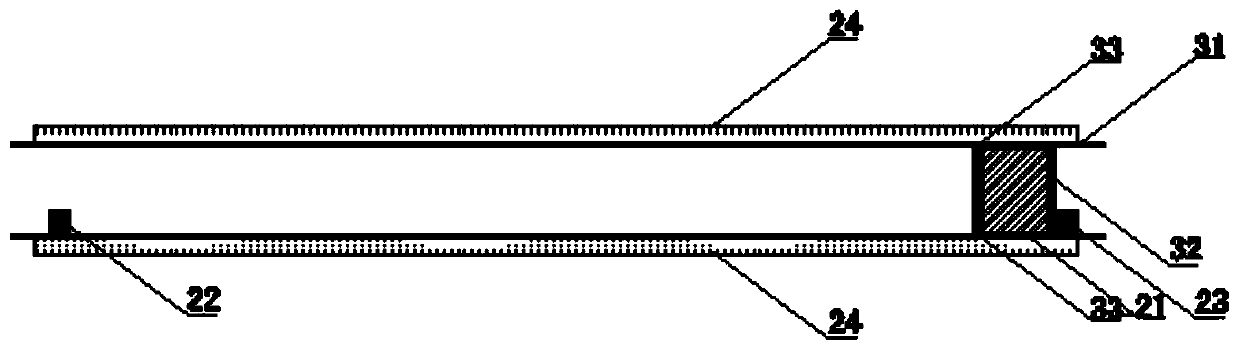

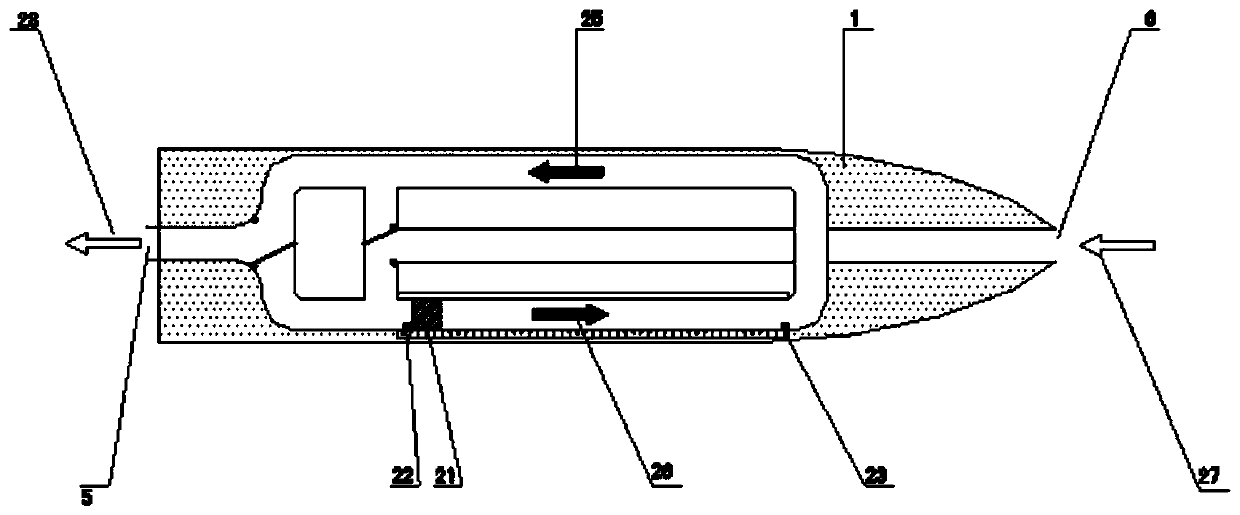

[0013] The present invention provides a kind of water-jet ship engine, installs an annular water flow propeller according to the length of the hull on the bottom or both sides of the bottom of the ship or warship 1, and the annular water flow propeller consists of a left channel arm 8 and a right channel arm 20. The front channel 7 and the rear channel 10 form a ring-shaped body, and in the axial direction of the center of the rear channel 10, a T-shaped water spray pipe 30 with the same diameter as the ring-shaped body is drawn in the opposite direction of the hull, and the water spray pipe diameter is waterproof. After sealing, it leads to the outer tail portion 3 of the hull, and is equivalent to the jet port of a turbofan engine for the thrust nozzle 5 . In the ring-shaped body near the rear channel, the left channel arm 8 and the right channel arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com