Flue gas circulation type steel plate medium and low-temperature tempering furnace and low-temperature control method

A technology of flue gas circulation and control method, which is applied in the direction of heat treatment process control, furnace, furnace type, etc., can solve the problems such as inability to strengthen convection with high pulse frequency, uneven temperature in width, and insignificant effect, and achieve uniform heating at low temperature. Good performance, reduce flue gas emissions, reduce the effect of high temperature performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

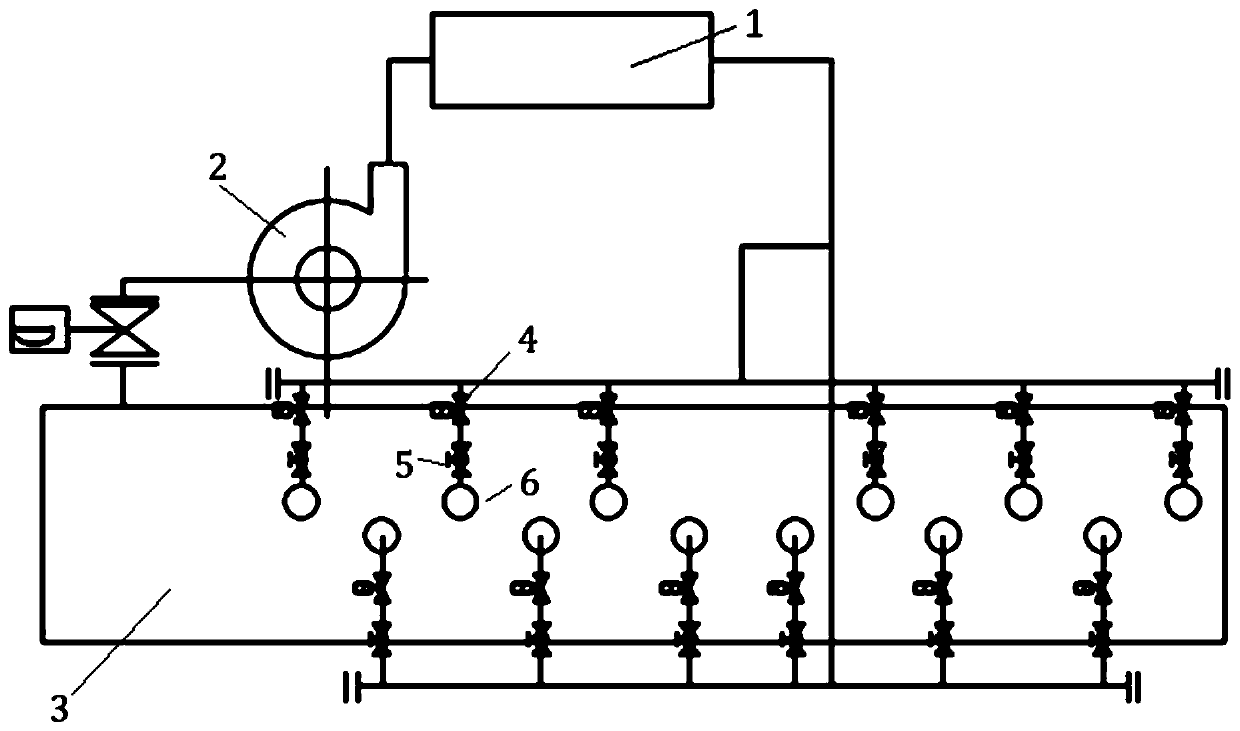

[0025] Example: Taking a heat treatment furnace with a temperature range of 150-800°C in a domestic factory as an example, the length of the heat treatment furnace is 79000mm, and the width is 3600mm. A set of flue gas circulation pulse jet system is designed for the whole furnace, see figure 1 .

[0026] The invention provides a medium-low temperature tempering furnace of a flue gas circulation type steel plate, and a set of flue gas circulation pulse jet system is arranged in the rear furnace area of the tempering furnace.

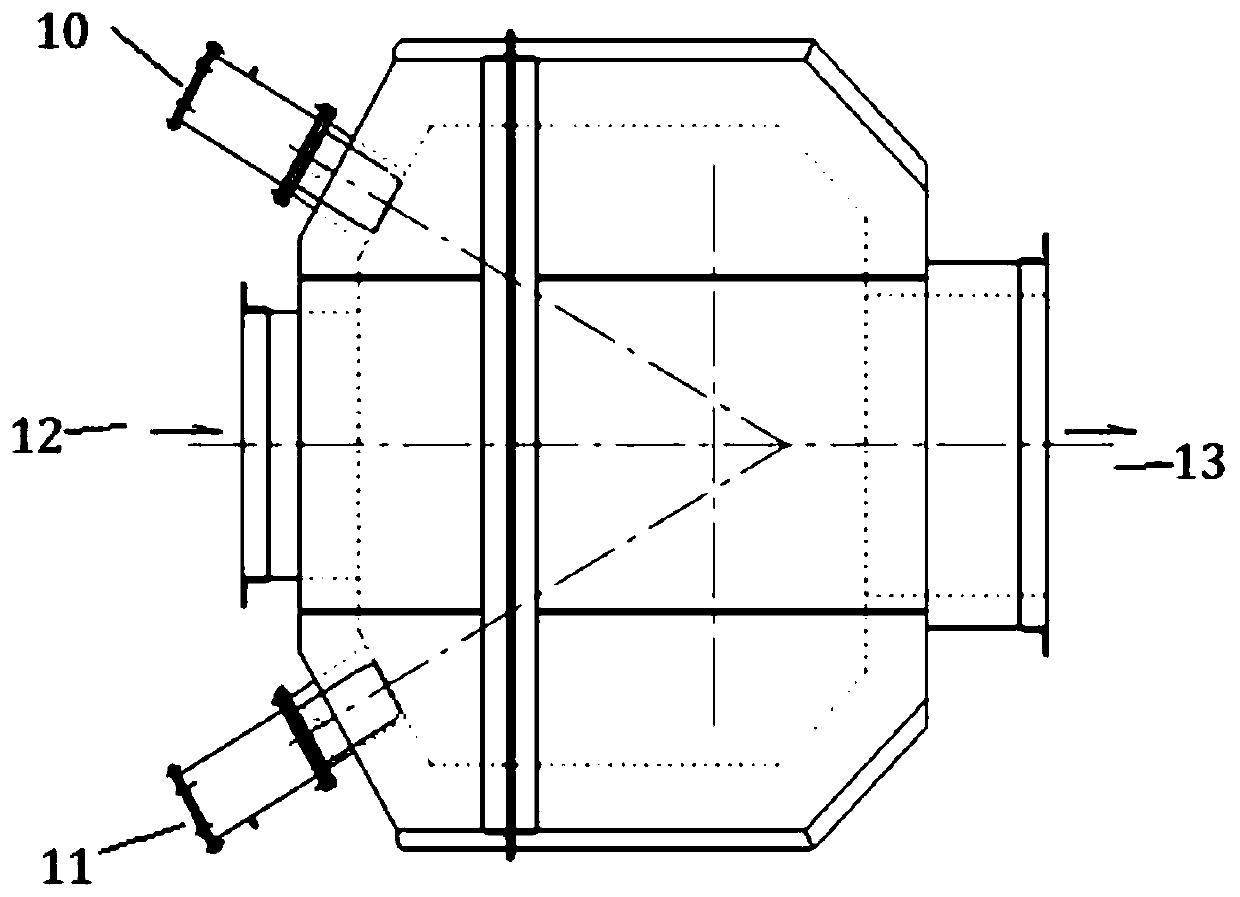

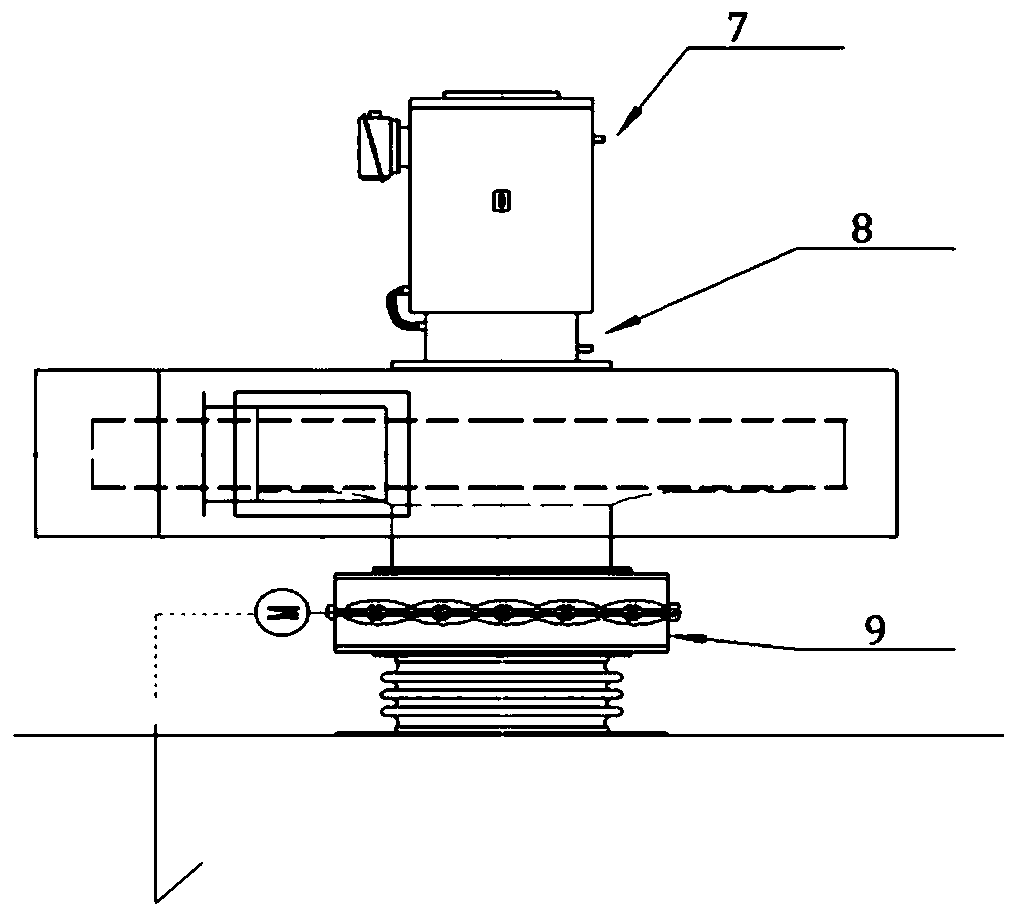

[0027] Such as figure 1 As shown, the flue gas circulation pulse jet system includes a circulating fan 2, an upper hot air nozzle, a lower hot air nozzle, a heat supplement temperature control device 1, and a diversion pipe; wherein both sides of the tempering furnace hearth are symmetrically arranged up and down along the furnace roller. Nozzles and upper and lower hot air nozzles, and the burners and hot air nozzles are arranged alternately; the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com