Independent support structure for prefabricated building construction and construction method

A technology for building construction and supporting structures, which is applied in building construction, on-site preparation of building components, construction, etc. It can solve the problems of supporting system force transmission path design, supporting system construction, prefabricated components and supporting can not be effectively contacted, etc. , to achieve the effects of saving support materials and on-site manpower, improving stability and reducing the number of layouts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

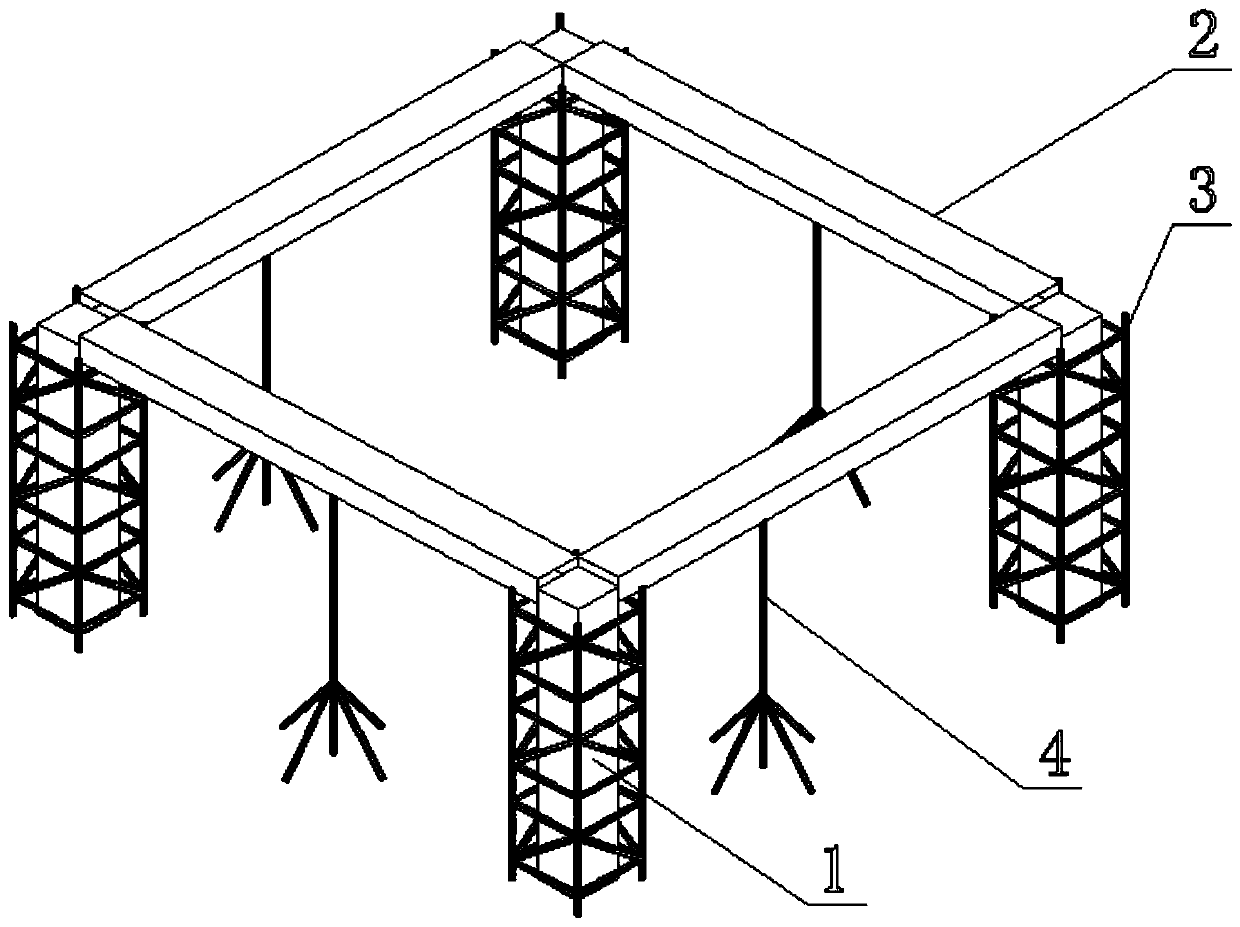

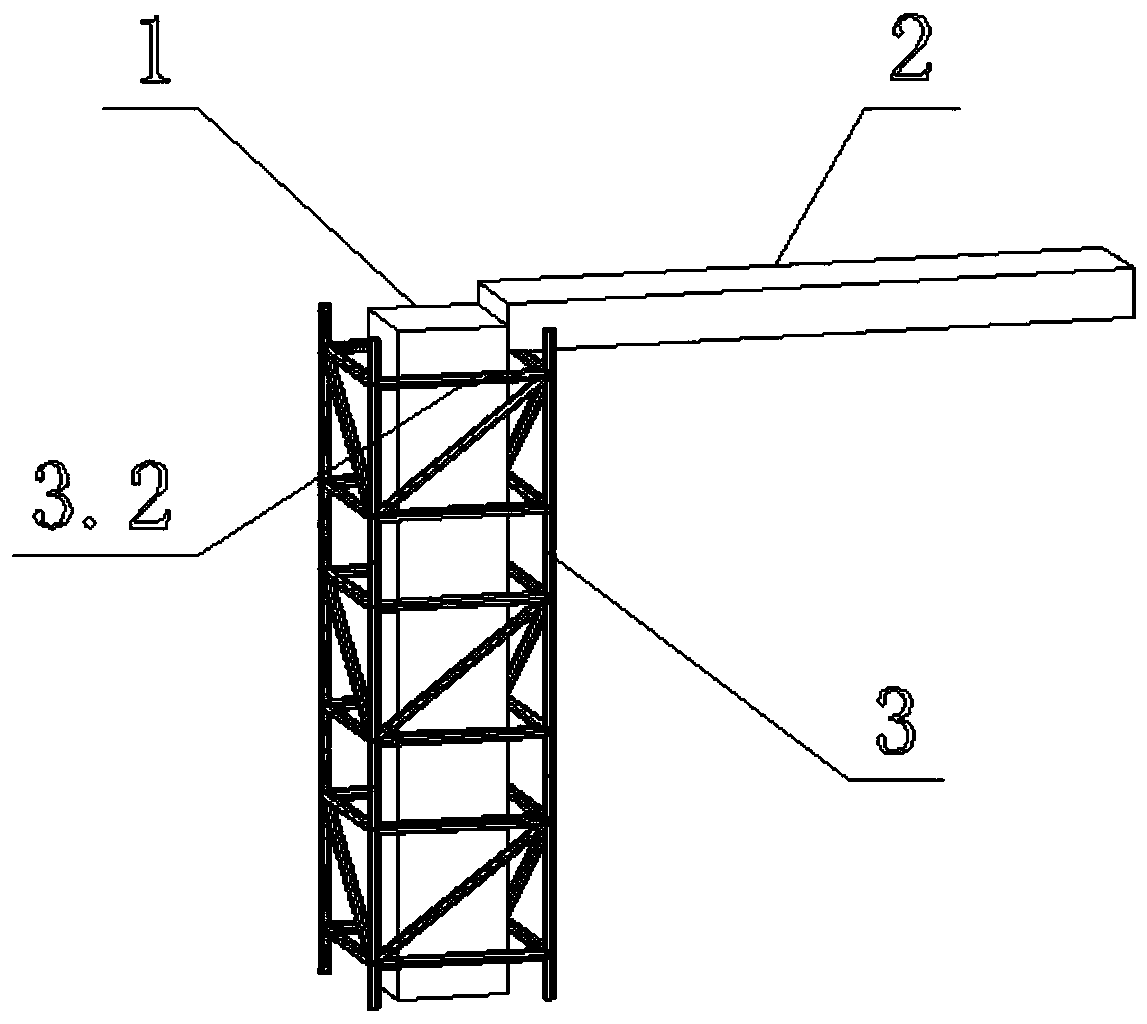

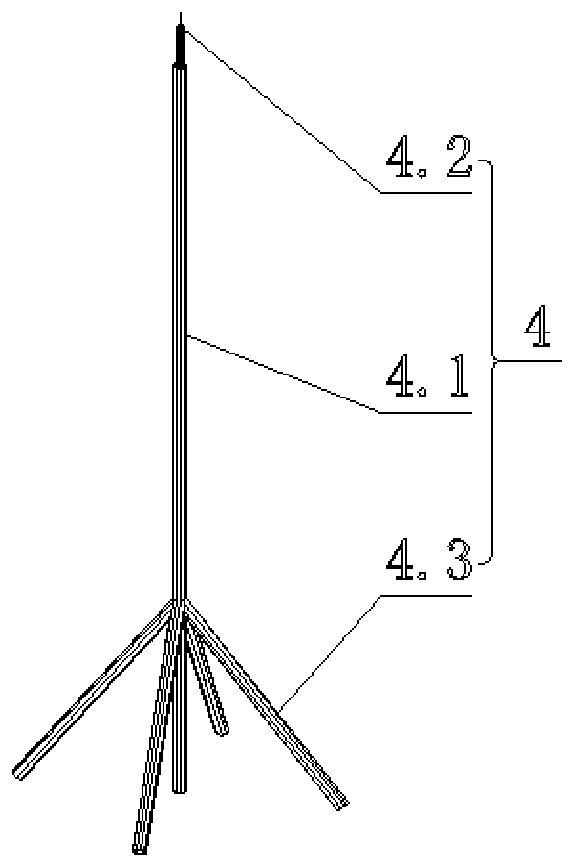

[0036] see Figure 1 to Figure 5 An independent support structure for prefabricated building construction includes prefabricated columns 1, prefabricated beams 2, fixed support groups and vertical supports 4; at least two prefabricated columns 1 are provided, and the two prefabricated columns 1 are parallel to each other, and the two prefabricated beams 2 The ends are respectively connected to the tops of two prefabricated columns 1; the prefabricated columns 1 are accommodated in the hollow structure of the fixed support group, and the fixed support group is set in one-to-one correspondence with the prefabricated column 1, and the fixed support group is used to support the prefabricated beam 2; the adjacent two At least one vertical support 4 is arranged between two prefabricated columns 1 to support the prefabricated beam 2, and the distance between two adjacent vertical supports is not greater than 2m.

[0037] In this embodiment, four prefabricated columns 1 are provided, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com