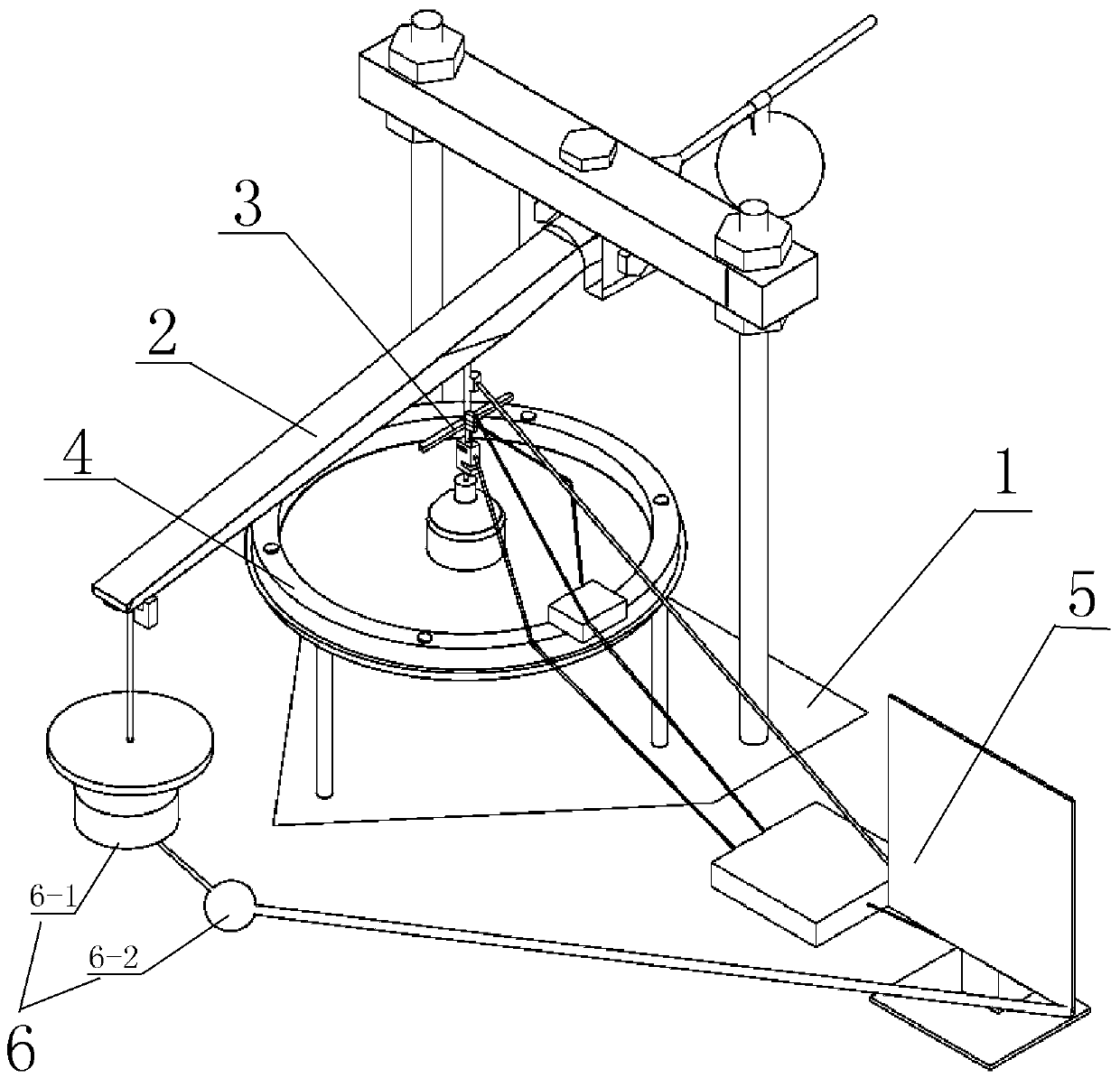

Geosynthetic material jacking creep test device

A geosynthetic material, creep test technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., to achieve the effect of reasonable design, convenient use and accurate experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1. The test method for measuring the top pressure creep performance of geosynthetics CBR using the above-mentioned device includes the following steps:

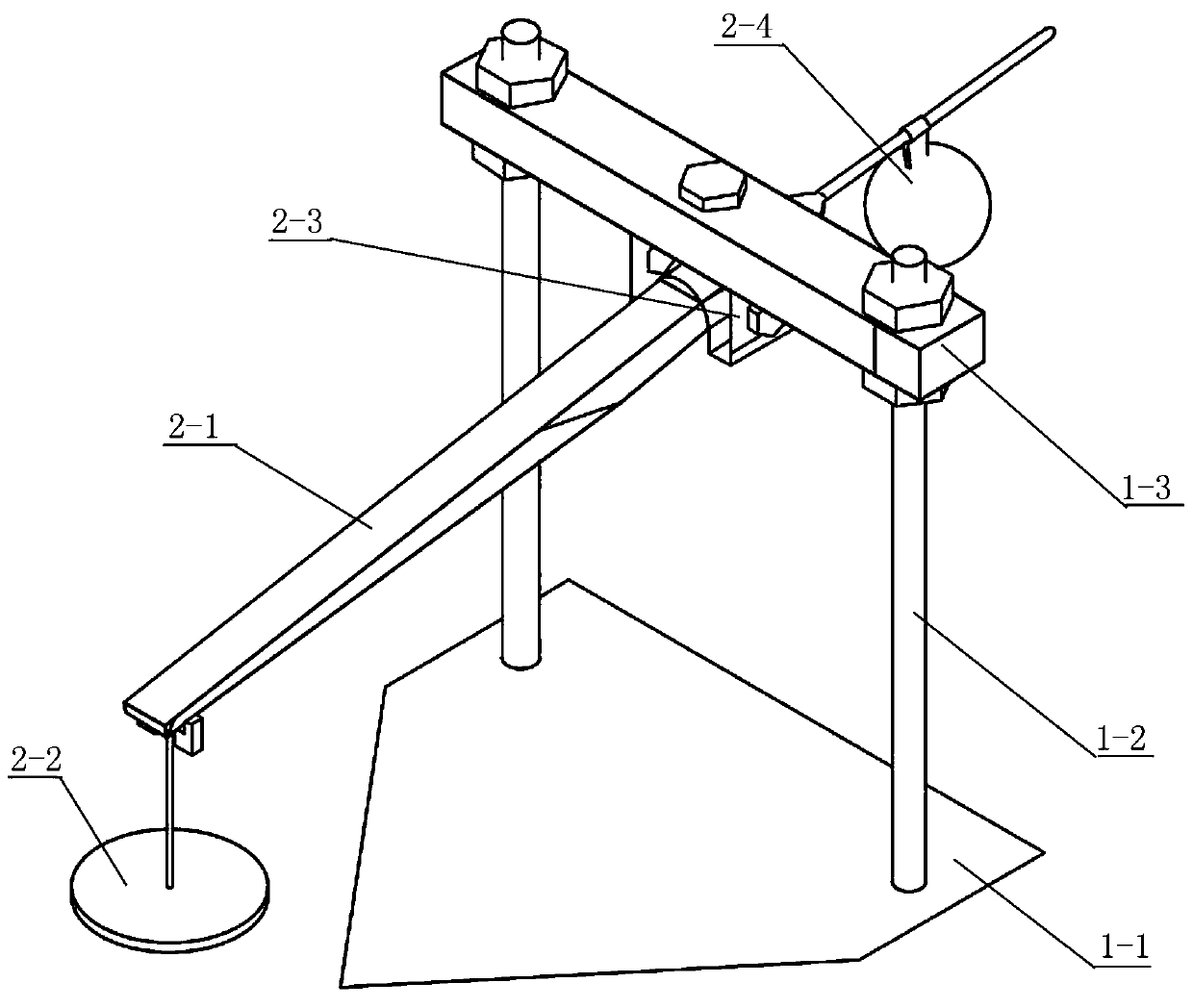

[0058] 1-1) Leveling lever

[0059] Use the lever leveling instrument to level the lever before the experiment, place the lever leveling instrument on the lever, adjust the position of the pressure hammer, make the small water drop of the lever leveling instrument in the middle of the leveling instrument, and then level the lever;

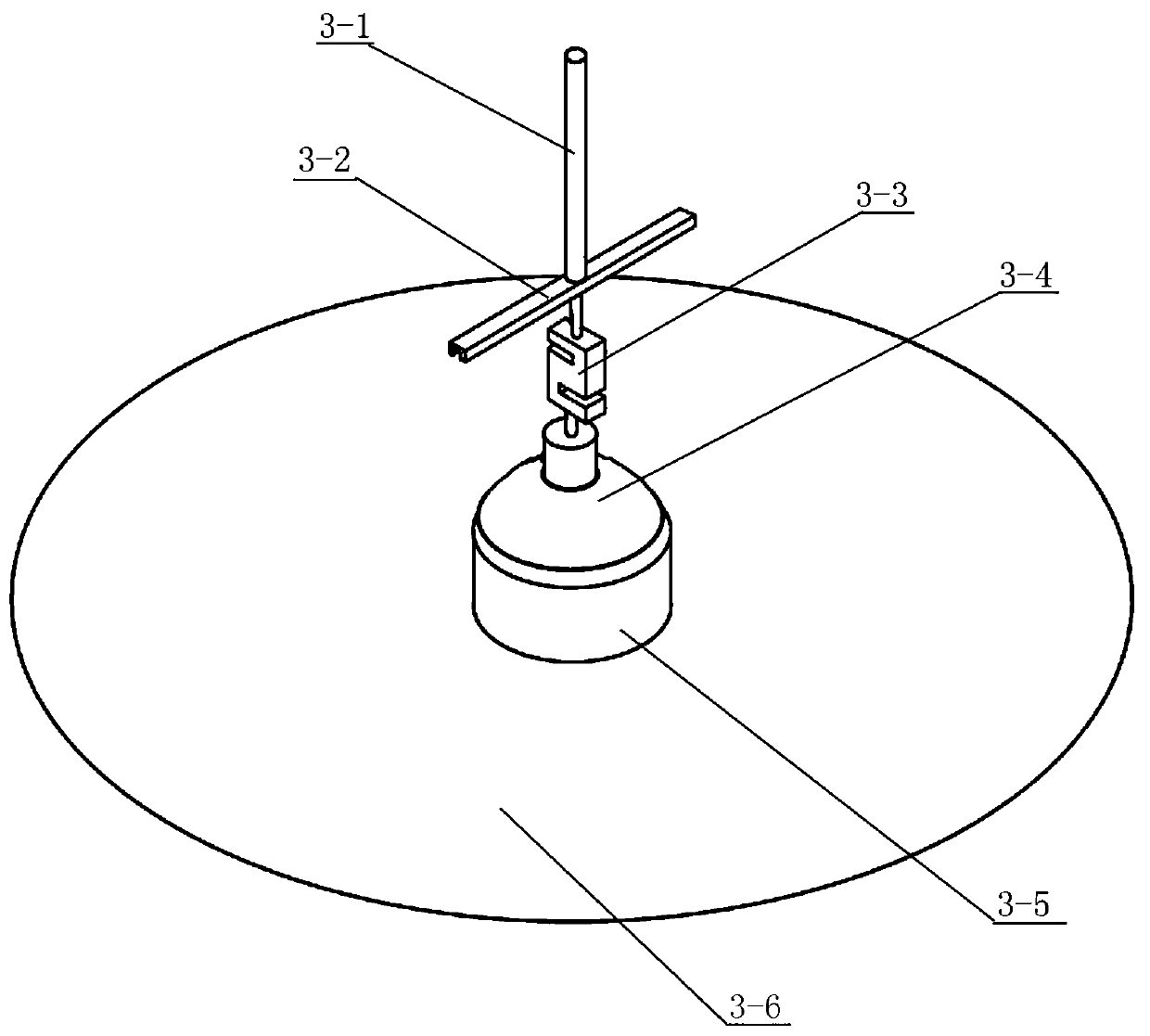

[0060] 1-2) Fixing of geosynthetics

[0061] The geosynthetics are tensioned and placed under the pressure plate of the directional bucket, and the clamp cover is placed on the pressure plate of the directional bucket. The geosynthetics and the pressure plate are fixed on the bracket with plum blossom nails, which can ensure that the directional bucket cover is clamped tightly. tighter;

[0062] 1-3) Adjust the position of the jig part

[0063] Adjust the position of the fixture part so ...

Embodiment 2

[0075] 2. The test method for measuring the puncture strength of geosynthetics using the above device, including the following steps:

[0076] 2-1) Leveling lever

[0077] Use the lever leveling instrument to level the lever before the experiment, place the lever leveling instrument on the lever, adjust the position of the pressure hammer, make the small water drop of the lever leveling instrument in the middle of the leveling instrument, and then level the lever;

[0078] 2-2) Fixing of geosynthetics

[0079] The geosynthetics are tensioned and placed under the directional barrel cover, and the clip cover is placed on the directional barrel cover. The geosynthetics and the directional barrel cover are fixed on the bracket by the plum blossom nails, which can ensure that the directional barrel cover is clamped tighter;

[0080] 2-3) Adjust the position of the jig part

[0081] Adjust the position of the fixture part so that the mouth of the directional bung is directly belo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com