Brake system and method for power & free control

A braking system and accumulative technology, applied in the field of logistics, can solve problems such as difficulty in realization and impact on the stability of the braking distance system, and achieve the effects of meeting control requirements, reducing back electromotive force, and increasing positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An accumulative control braking system is suitable for accumulative transport of standard parts in airports, wharves, factory automation, etc. by means of conveyor lines. When the conveyor line is transported at high speed, it can accurately stop the goods with known shape at the position of the sensor module, so as to realize the precise positioning and tracking of the goods on the conveyor line, reduce the failure rate of system control, and reduce the blockage of conveyed goods.

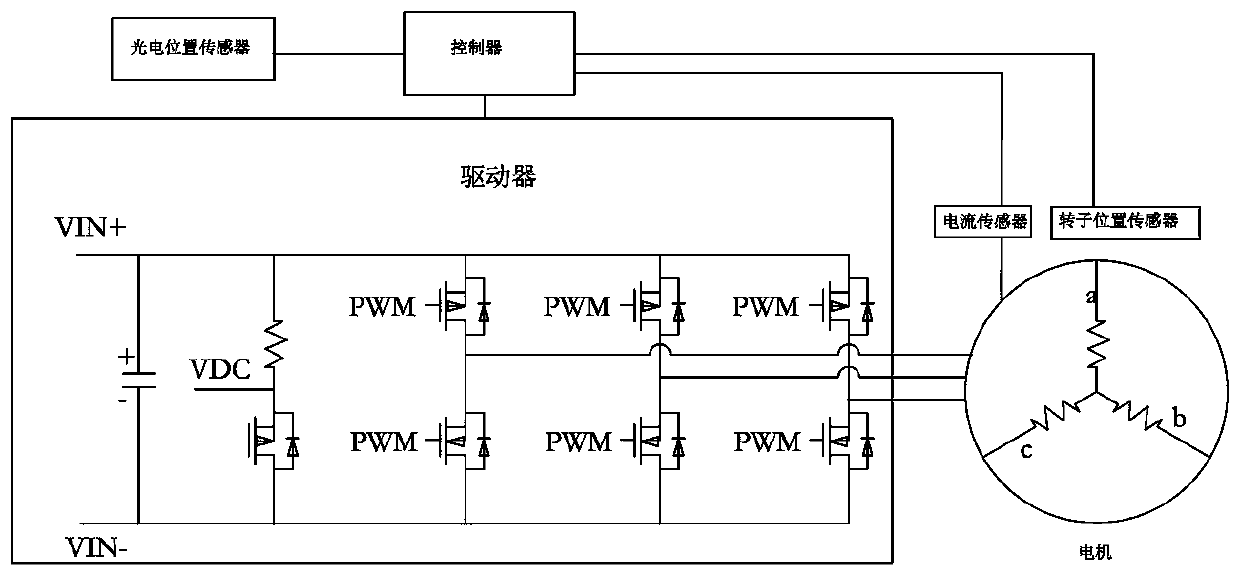

[0030] The driving device in this embodiment includes a driver and a controller. The driver is used to output corresponding driving current to the motor according to the received pulse width modulation signal to control the rotation of the motor. The pulse width modulation signal may be an SPWM signal or an SVPWM signal, and the SVPWM signal is used for modulation in this embodiment. The power inverter of the driver outputs corresponding three-phase AC power to the motor according to the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com