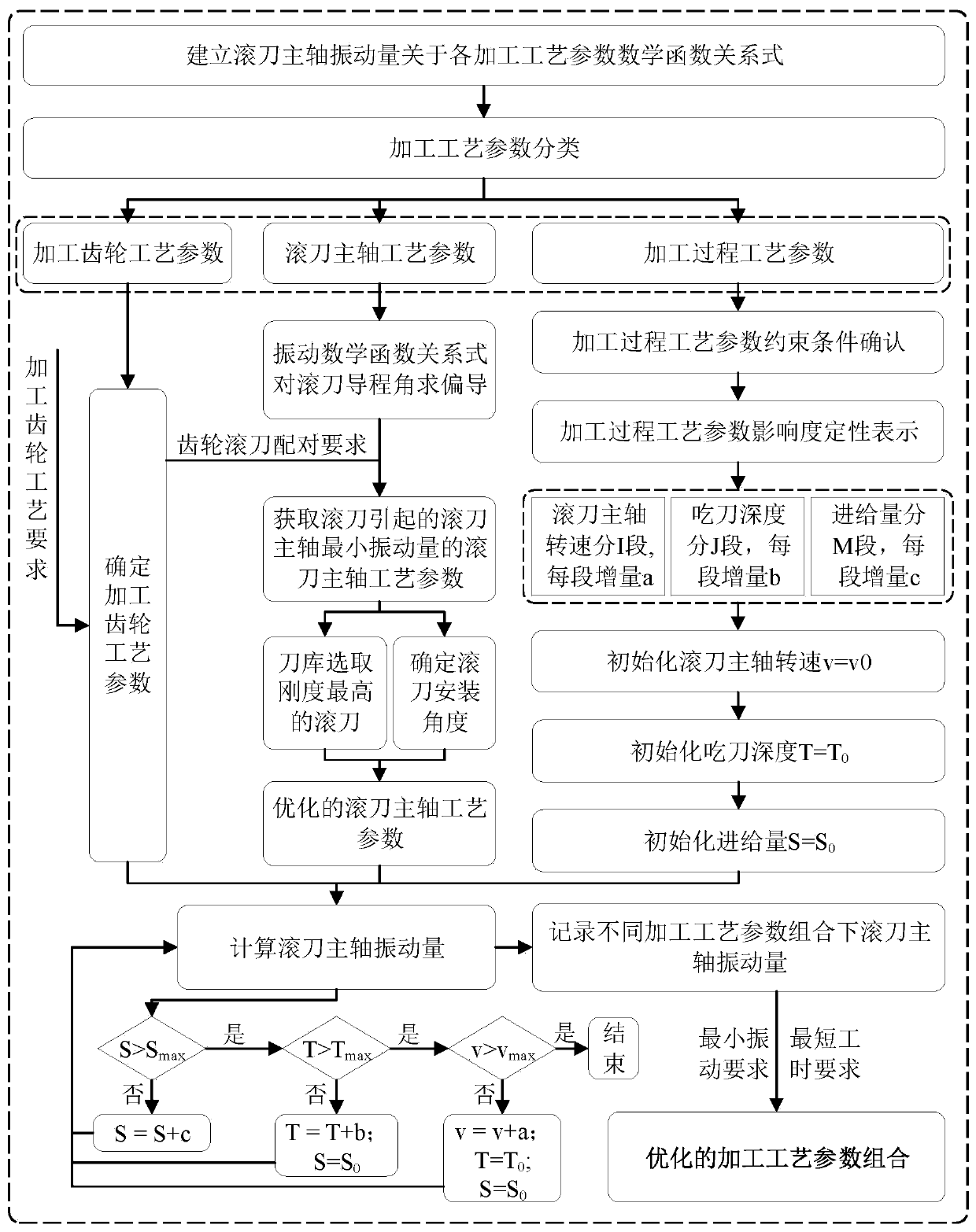

Hobbing process parameter optimization method based on hobbing cutter spindle vibration response model

A technology for process parameter optimization and process parameter application in electrical digital data processing, special data processing applications, instruments, etc., can solve the problem of spending a lot of time and energy, and achieve the effect of high reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

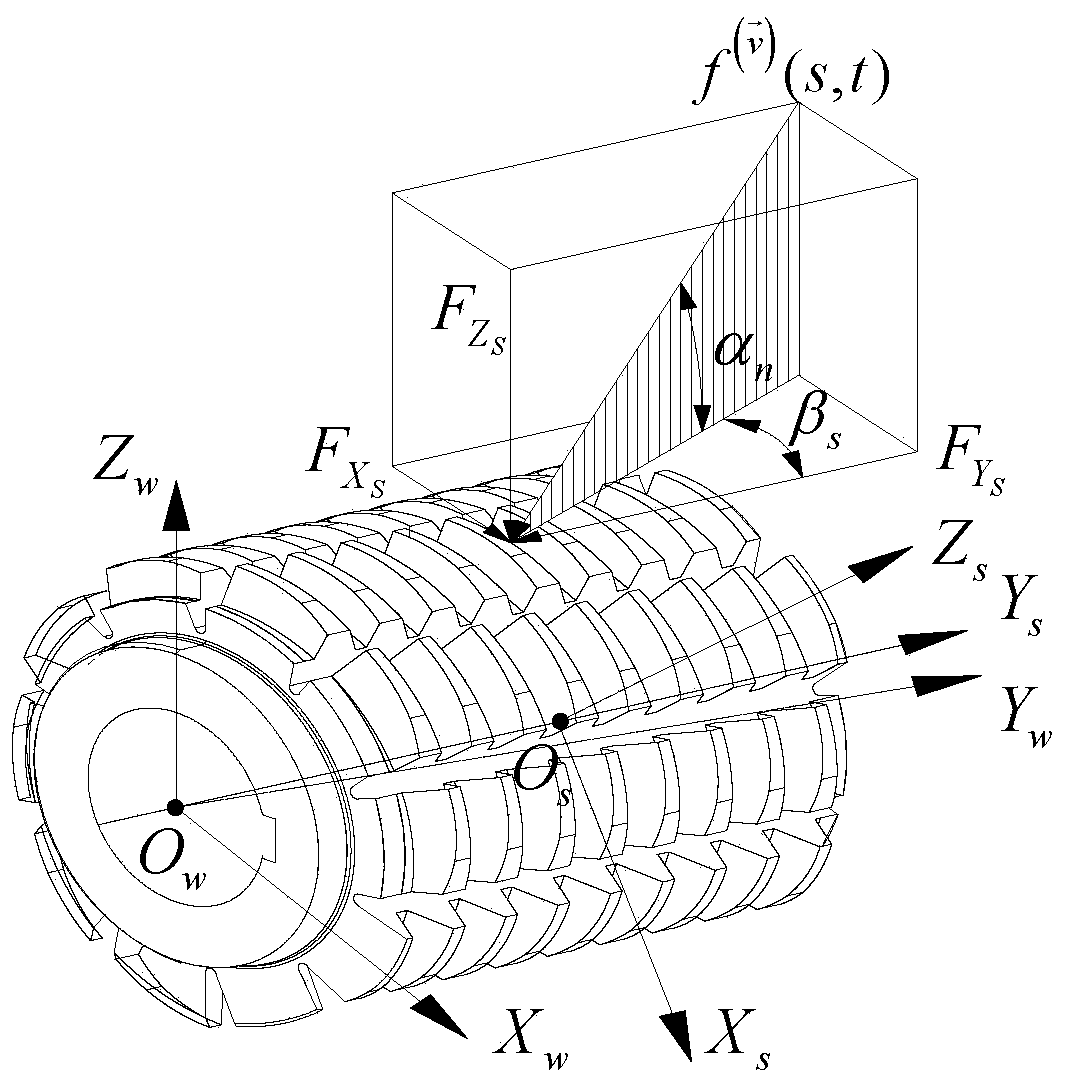

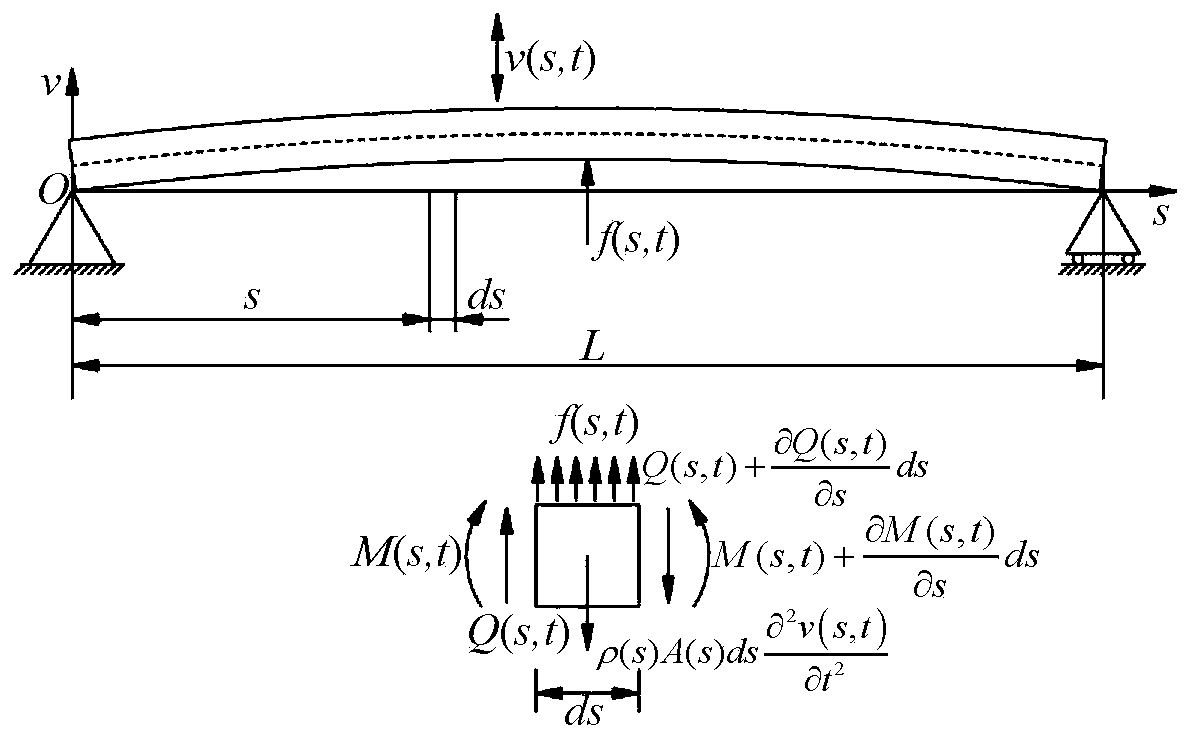

[0039] In order to make the purpose, technical solution and advantages of the present invention clearer, the vibration response characteristics of the hob spindle under the consideration of the processing parameters will be analyzed below in conjunction with the accompanying drawings:

[0040] 1. Analysis of the inherent characteristics of the hob spindle vibration

[0041] The vibration of the hob spindle during processing is divided into bending vibration, torsional vibration and longitudinal vibration. In view of the fact that torsional vibration and longitudinal vibration have less influence on the deformation of the spindle than bending vibration, this paper only lists the bending vibration response of the hob spindle analyze. This chapter solves the free vibration state by establishing the balance equation of vibration mechanics, and finally obtains the calculation formula of the natural frequency of the hob spindle and the main vibration modes of each order.

[0042] 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com