New energy automobile power battery system based on heat pipe and phase change material

A new energy vehicle and phase change material technology, applied in the field of new energy vehicle power batteries, can solve the problems of increasing pipeline freezing, bursting, and difficulty in solving battery thermal management problems at low temperatures, and achieve good temperature uniformity and fast heat transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

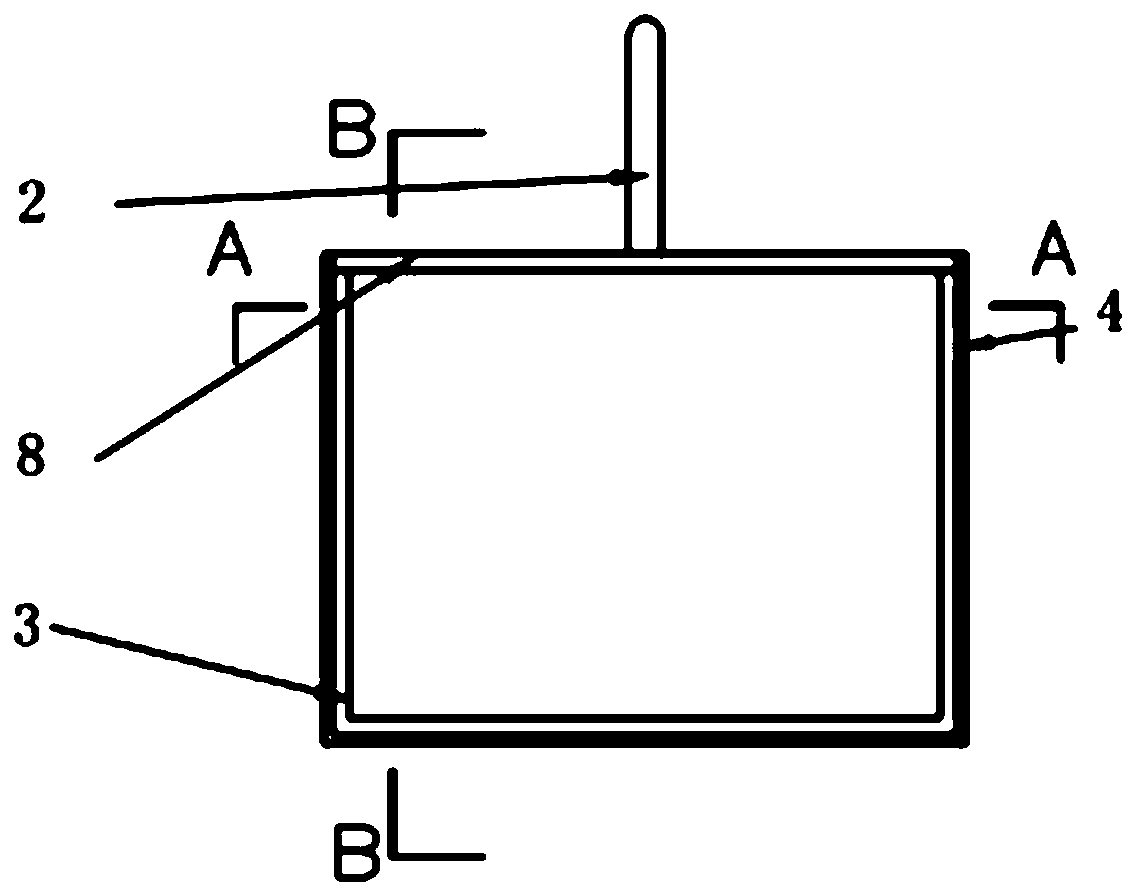

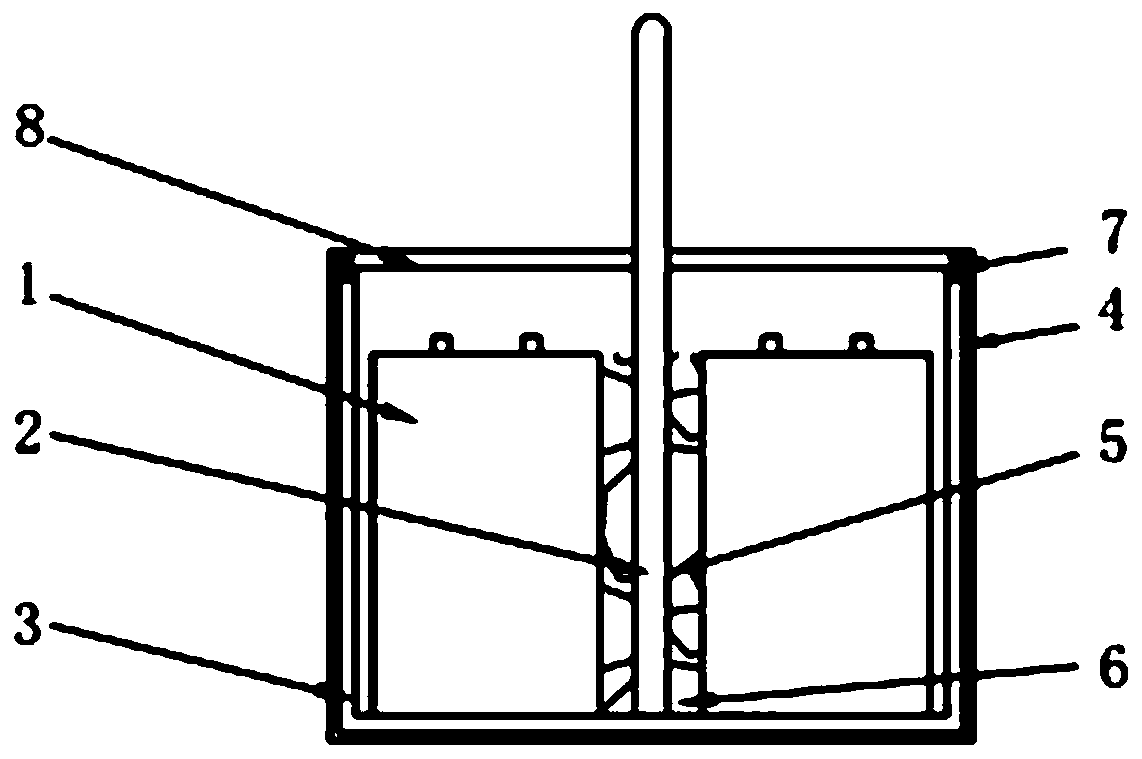

[0046] Embodiment 1. The temperature in some areas in winter is relatively low, which has a huge impact on the operation and storage of the power battery 1. The present invention utilizes a large amount of heat generated by the battery 1 during operation and stores this heat in the phase change material 6 through the transfer of the heat pipe 2. When the battery 1 stops operating and the temperature drops to a certain level, the heat stored in the phase change material 6 will It is transferred to the battery box 3 through the heat pipe 2 so as to achieve the purpose of heat preservation.

Embodiment 2

[0047] Embodiment 2. The heat preservation process after the electric vehicle battery 1 stops running is as follows:

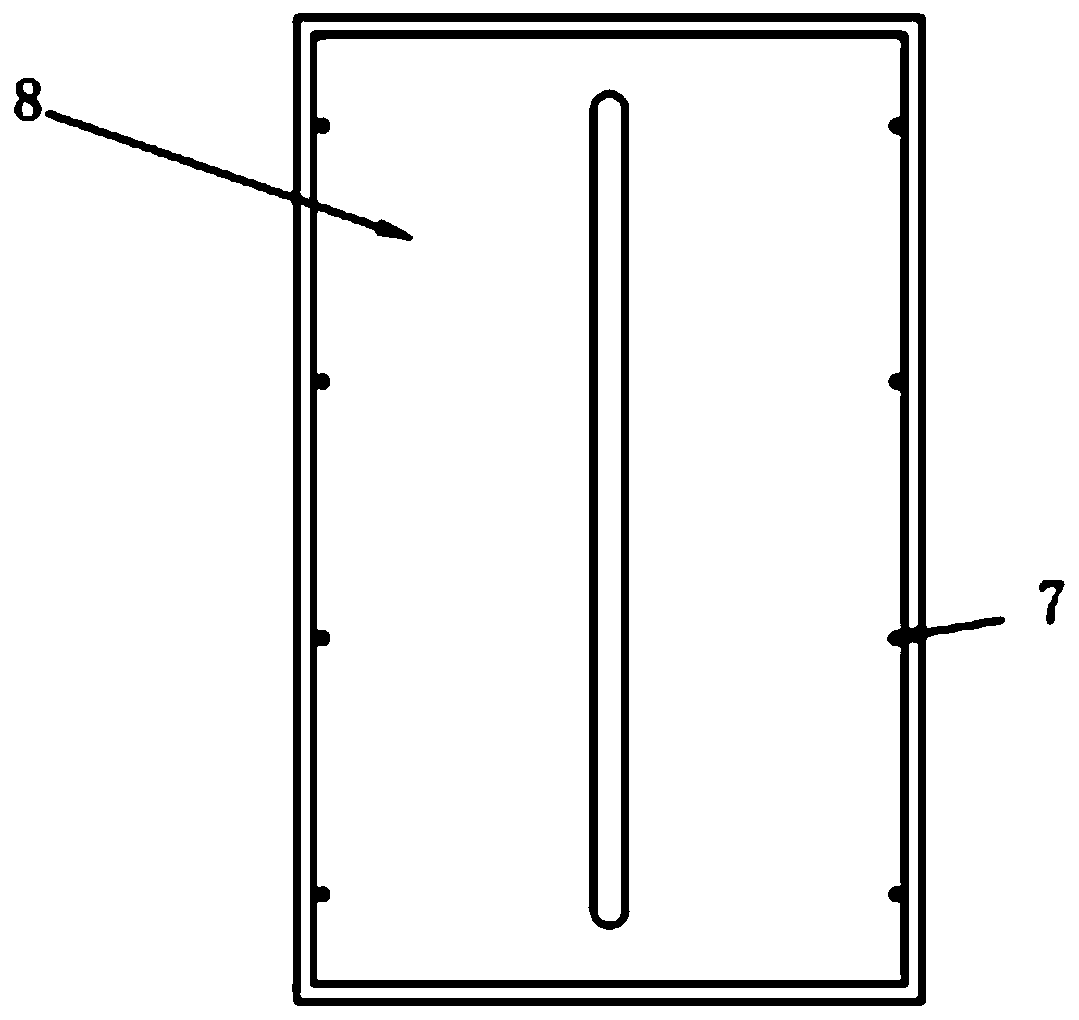

[0048] Such as figure 2 As shown, the battery 1 in the electric vehicle battery box 3 is composed of multiple battery cells, which together form a battery pack to provide energy for the electric vehicle. The temperature of the battery 1 rises to a certain extent during operation, the metal frame 55 is heated and expands and contacts the heat pipe 2, and the heat pipe 22 is activated to transfer the generated heat to the outside environment through the heat pipe 22.

[0049] After the battery 1 is discharged and the temperature is gradually reduced to a certain level, the metal frame 55 is cold-shrinked and disconnected from the heat pipe 2, and the heat stored in the phase change material 66 is transferred to the vicinity of the battery 1 for heat preservation of the battery 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com