Preparation method of industrialized fermented green vegetables

The technology of green vegetables and fermentation tank is applied in the field of preparation of industrialized fermented green vegetables, which can solve the problems of difficult control of fermented taste and low compliance rate of fermentation quality, and achieve the effects of easy maintenance of color and taste, improvement of fermentation quality, and complete color and aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

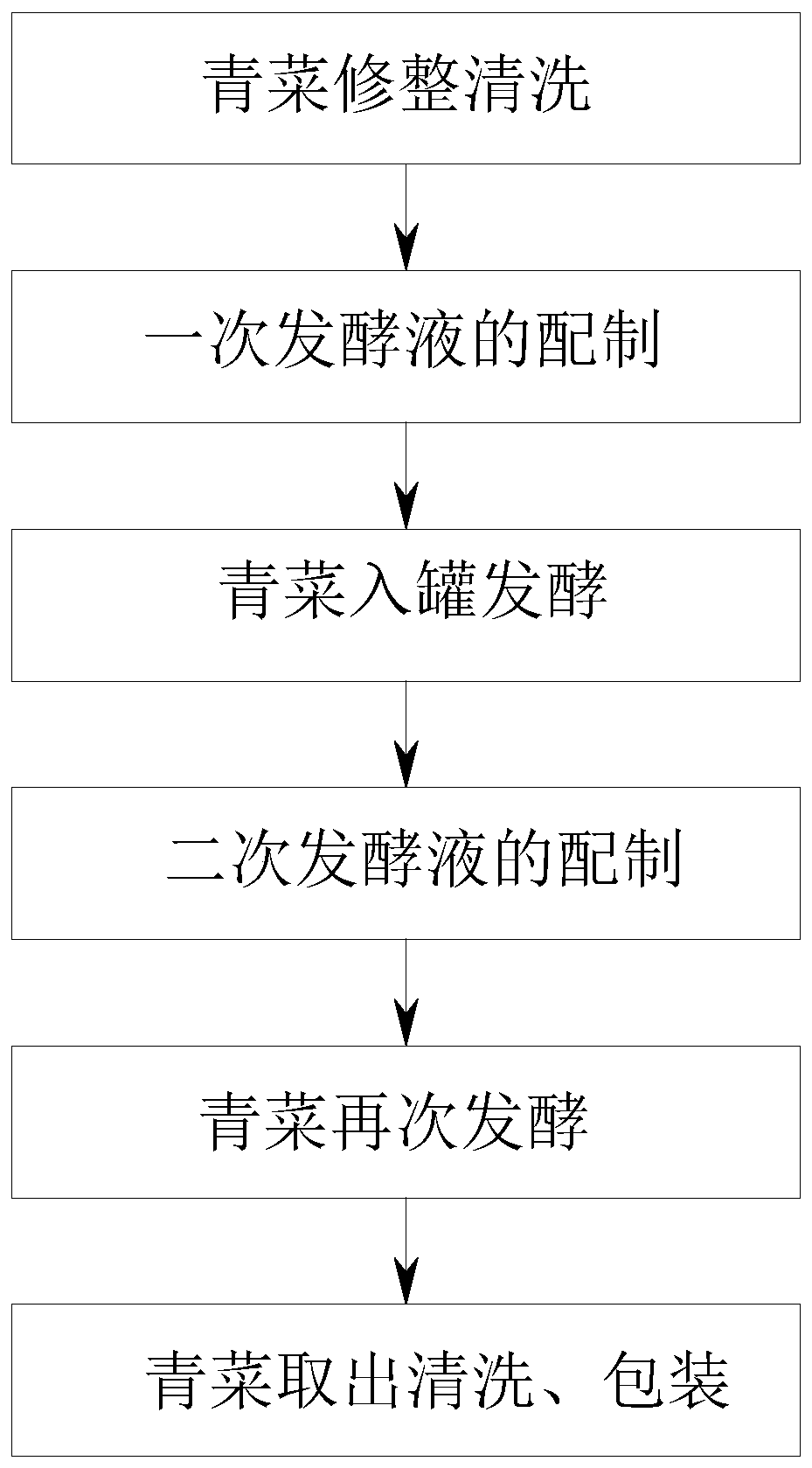

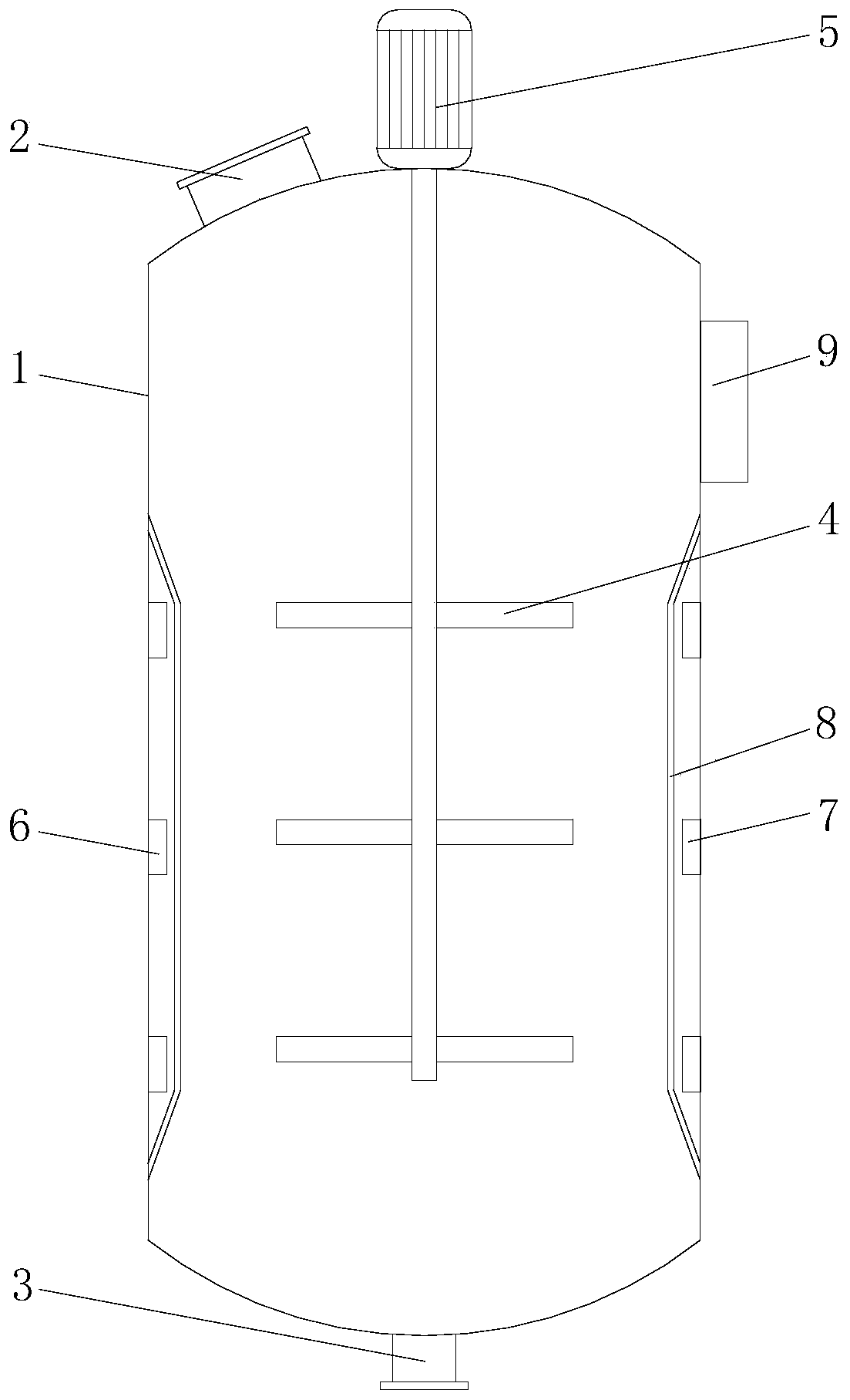

[0025] Such as Figure 1-2 As shown, the present invention provides the following technical solutions: a method for preparing industrialized fermented vegetables, the method comprising: cleaning the vegetables, removing the inedible parts, and cutting them appropriately; Lactobacillus, yeast and acetic acid bacteria are prepared, fully mixed and stirred evenly; half of the processed green vegetables are put into the fermenter and then put into a mixed spice bag, and the mixed spice bag is wrapped with gauze, and then the remaining green vegetables are packed. Inject the prepared primary fermentation liquid, soak the vegetables in the primary fermentation liquid, cover and seal, and start fermentation; after 7-10 days of primary fermentation, discharge the internal raw liquid through the drain at the bottom of the fermentation tank to prepare the secondary fermentation liquid , the secondary fermentation liquid is prepared by hard water, mother liquor, brown sugar and white sug...

Embodiment 1

[0028] Step S1, washing the vegetables, removing the inedible parts, and cutting them appropriately;

[0029] Step S2, configure a fermented liquid, the primary fermented liquid is prepared by hard water, edible salt, Lactobacillus plantarum, yeast and acetic acid bacteria, fully mixed and stirred evenly, the hardness of hard water is set between 180-220 mg / L, in step S2 The primary fermentation broth is made by fully mixing and stirring 2-6 parts of edible salt, 0.1-1 part of Lactobacillus plantarum, 0.1-0.5 part of yeast, 0.1-0.2 part of acetic acid bacteria and hard water;

[0030] Step S3, put half of the processed green vegetables into the fermenter 1 and put them into the mixed spice bag, wrap the mixed spice bag with gauze, then pack the remaining green vegetables, inject the primary fermentation liquid prepared in step S2, and make the green vegetables Soak in the primary fermentation liquid, cover and seal, and start fermentation. The fermentation temperature of the f...

Embodiment 2

[0035]The difference between this embodiment and Example 1 is that, in the secondary fermentation in step S4 of this embodiment, 3% white sugar, 3% brown sugar, 25% mother liquor, and 5% seasonal Vegetables and 54% hard water are cyclically mixed and fermented under constant temperature conditions. When the acidity reaches 0.7-1, the secondary fermentation is considered complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com