Graphene protective layer and molding method thereof, compound thread fastening part and compound gear

A forming method and composite gear technology, applied in the direction of belts/chains/gears, coatings, components with teeth, etc., can solve problems such as difficulty in fully exerting the effect of graphene coatings and graphene coatings falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

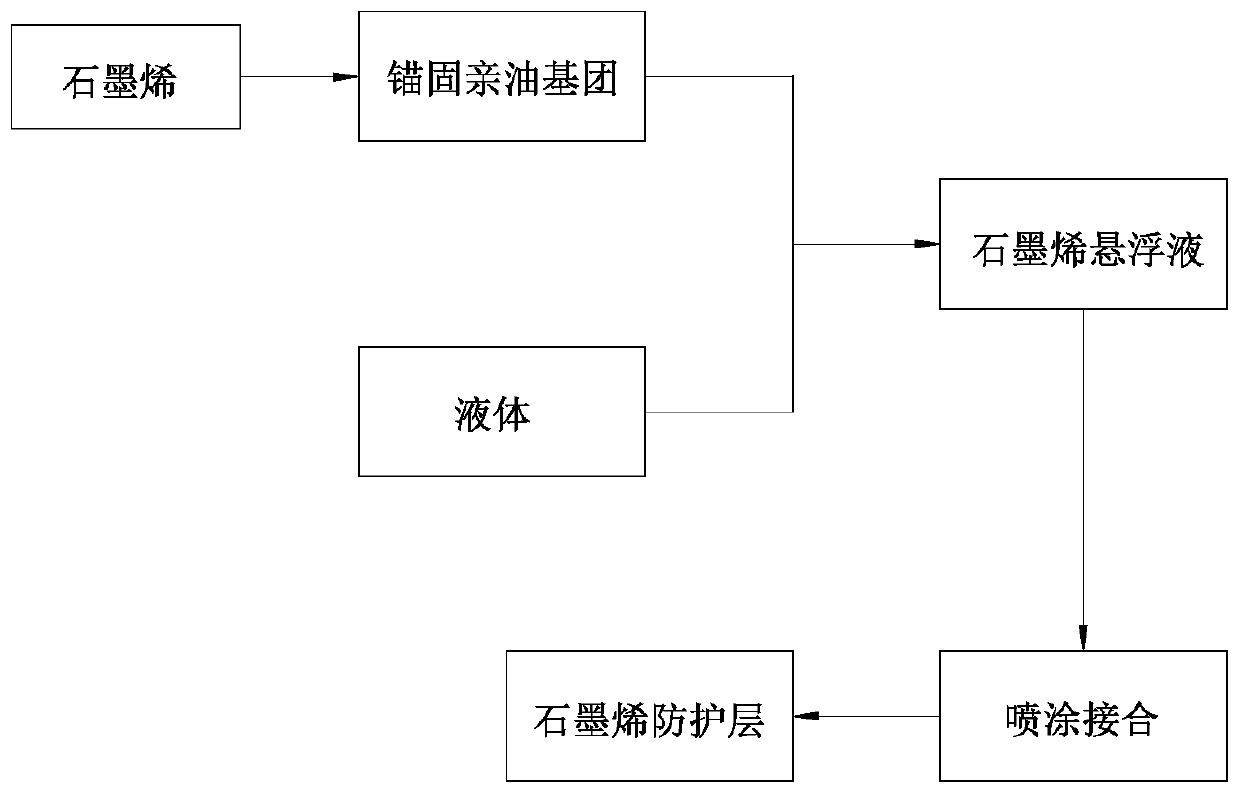

[0018] The embodiment of the forming method of graphene protective layer

[0019] Such as figure 1 As shown, the forming method of the graphene protective layer of the present invention first disperses the graphene anchored with lipophilic groups in a liquid to make a graphene suspension. By spraying the graphene suspension, the graphene suspension is sprayed at an initial spraying speed greater than 381m / s, and the graphene is spread on the surface of the resin matrix to form a graphene protective layer.

[0020] Preferably, the initial spraying velocity of the graphene suspension is greater than 420m / s. It is beneficial to further improve the initial kinetic energy of graphene suspension injection, and enhance the anchoring effect and binding force between the lipophilic groups of graphene and the groups of the resin matrix.

[0021] Preferably, the distance between the nozzle for spraying the graphene suspension and the resin matrix is less than 5.5 cm. It is beneficia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com