A processing technology of road and bridge truss pieces

A sheet processing and truss technology, which is applied in the field of road and bridge truss sheet processing technology, can solve problems such as low processing efficiency of truss sheets, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0047] Aiming at the problem of low processing efficiency of the existing truss pieces, the invention provides a road and bridge truss piece processing technology.

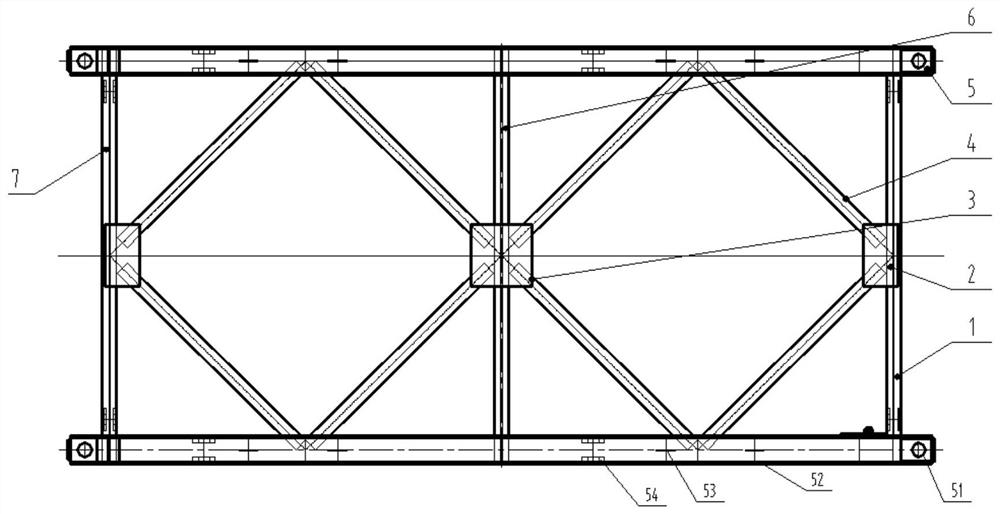

[0048] Such as Figure 1-8 As shown, the embodiment of the present invention provides a road and bridge truss piece processing technology, the truss piece processing technology includes:

[0049] S1, component welding, using the assembly platform to automatically assemble and automatically weld the parts that constitute the components, the components include chords 5 and vertical bars, and each of the components has a corresponding assembly platform, so The assembly platform can be assembled and welded at the same time;

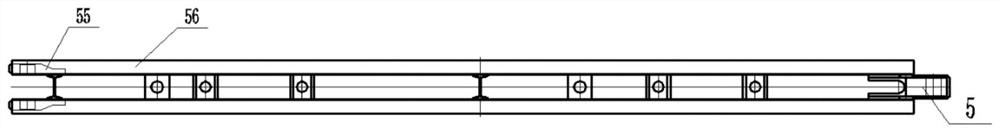

[0050] The chord 5 includes a male head 51, two channel steels 56 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com