Inspection specimen device

A test piece and clamping technology, which is applied in the field of testing test piece devices, can solve the problems of easy contamination of the sample, lower test accuracy, and easy detachment, so as to reduce the probability of sample contamination, improve test accuracy, and improve The effect of binding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

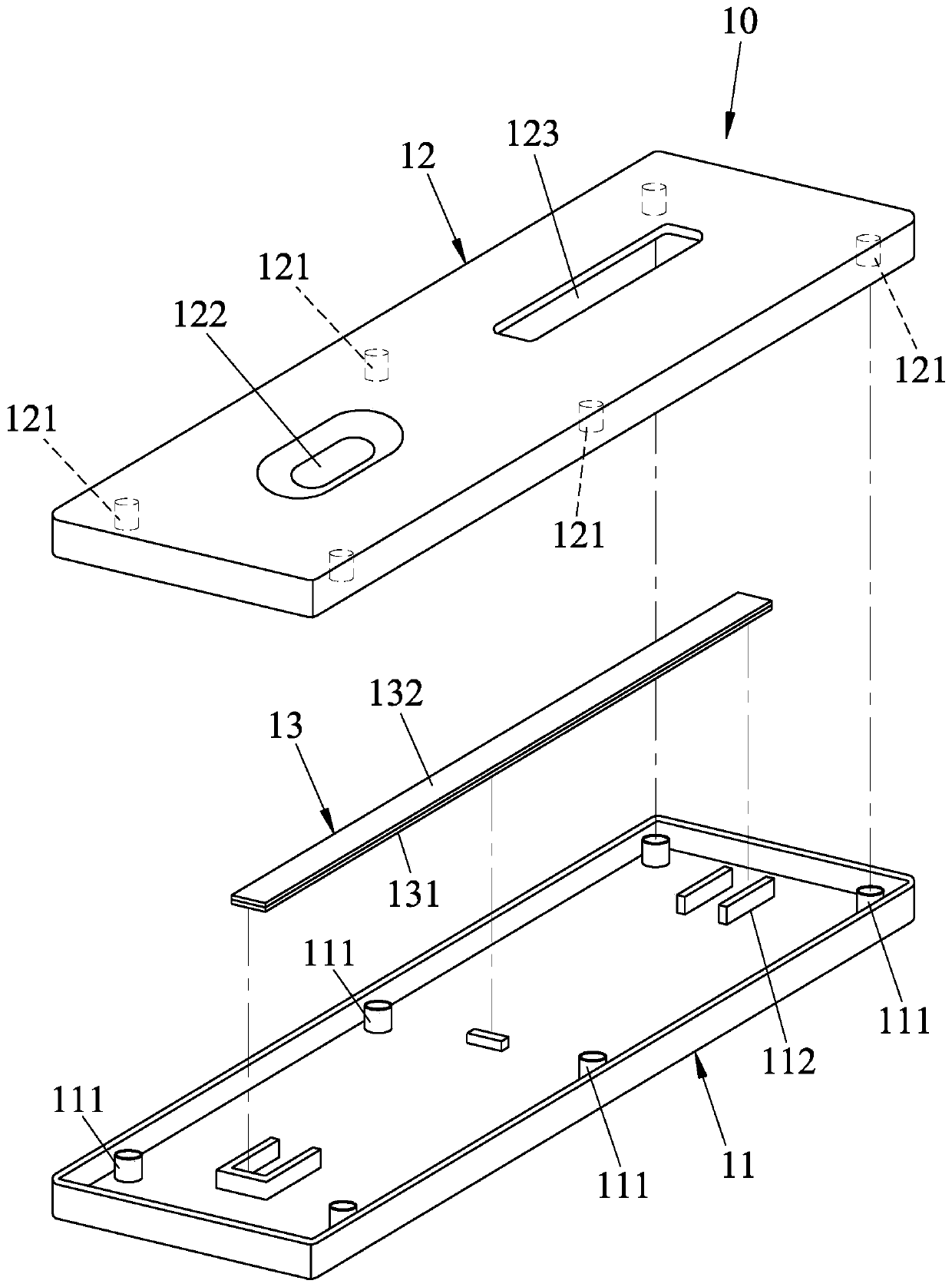

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

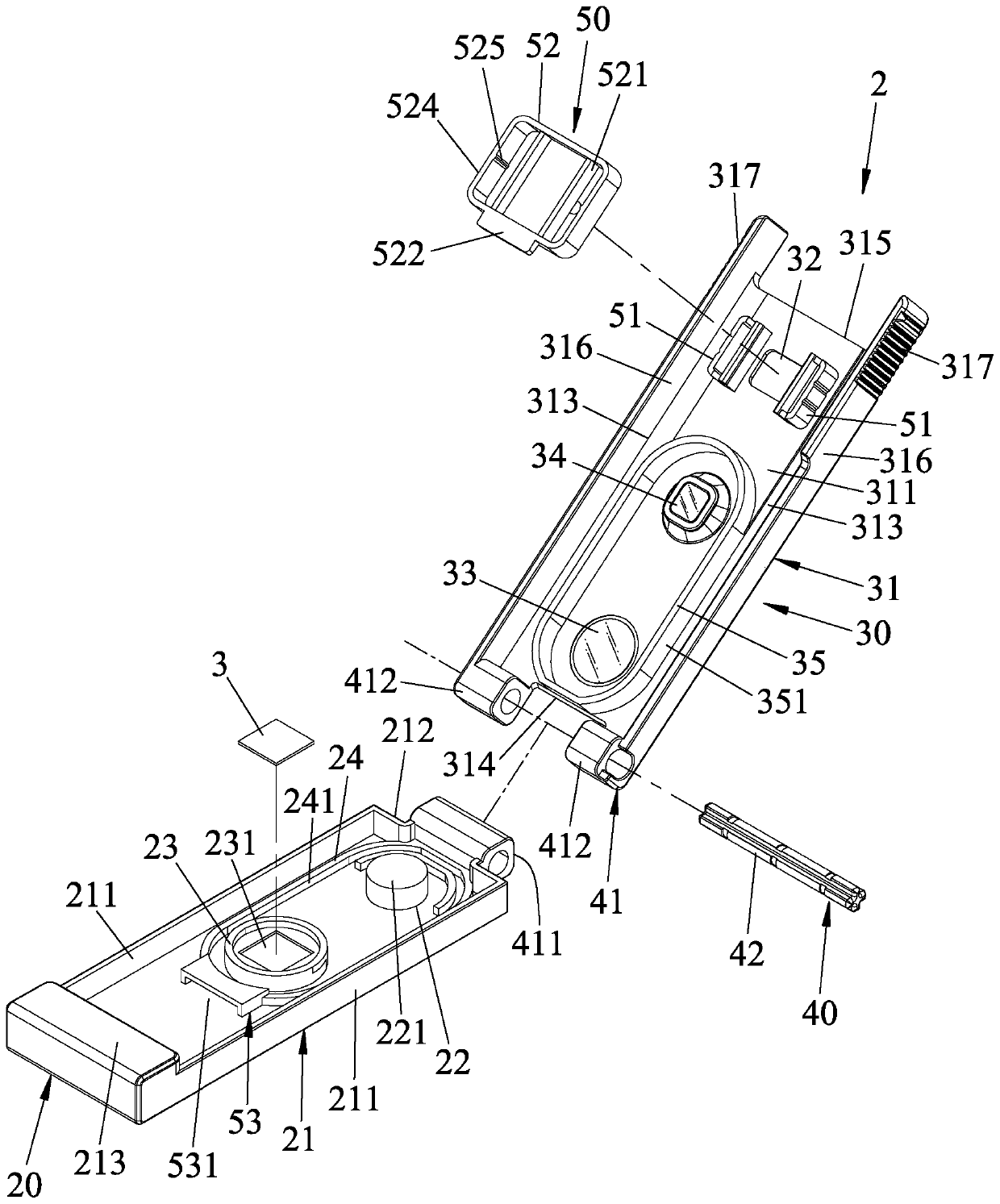

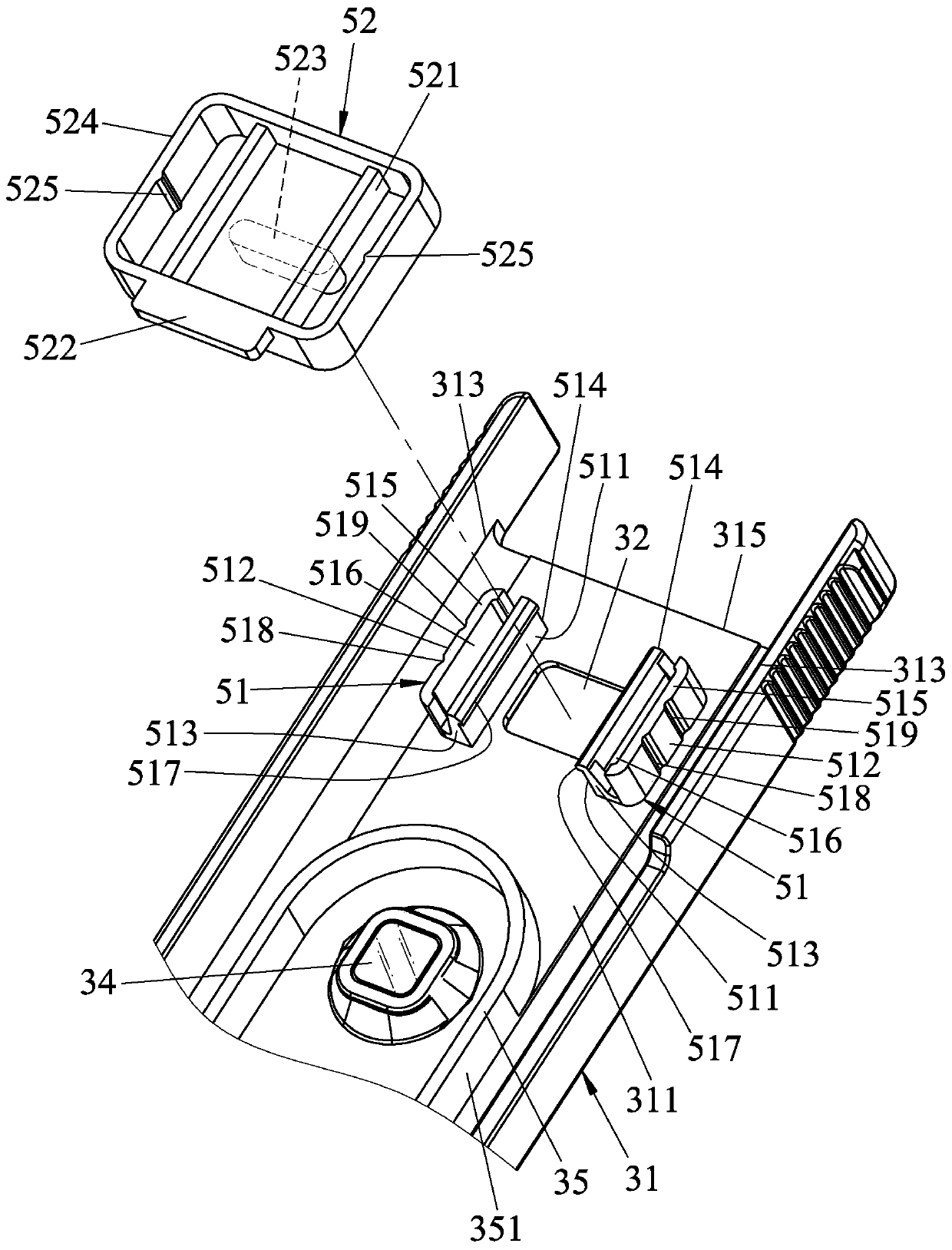

[0035] refer to figure 2 , an embodiment of the testing strip device 2 of the present invention includes a base unit 20 , a top cover unit 30 , a pivot unit 40 and a locking unit 50 .

[0036] The base unit 20 includes a base body 21 , a first inspection portion 22 , a second inspection portion 23 and a bottom wall 24 .

[0037] The seat body 21 has two parallel side walls 211 spaced apart from each other, and a first connecting wall 212 and a second connecting wall 213 connecting the side walls 211 .

[0038] The first inspection part 22 and the second inspection part 23 are arranged on the seat body 21, and the first inspection part 22 is close to the first connecting wall 212, and the second inspection part 23 is located between the first inspection part 22 and the first connection wall 212. between the second connecting walls 213 . In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com