Airgel lightweight thermal fabric and manufacturing method thereof

A production method and airgel technology, which is applied in liquid/gas/steam textile material processing, dyeing method, rayon manufacturing, etc., can solve the problems of inability to achieve lightness, limited thermal performance, etc., and reduce the dyeing rate , avoid easy color flower, high warmth retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

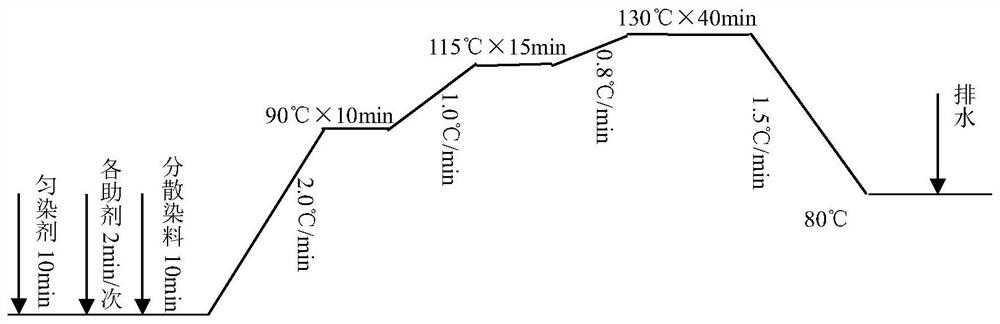

[0032] The manufacture method of the airgel lightweight warm-keeping fabric of the present embodiment has the following steps:

[0033] S1: Preparation of airgel fibers.

[0034] After the polyester spinning solution is melted, the airgel powder is added to the spinning solution online before spinning to achieve a uniform state; then it is sprayed out through the spinneret hole, and then the fiber is formed, the primary fiber is drawn and oriented, The fibers are heat-set and wound to produce airgel fibers.

[0035] The fineness of the airgel fiber prepared in this example is 75D.

[0036] S2: Weaving the airgel fiber prepared in step S1 as a yarn into a fabric.

[0037] The weft knitting unidirectional machine is used for weaving, and the number of knitting needles matches the denier number of the airgel fiber yarn.

[0038] S3: Dyeing and finishing the fabric obtained by weaving in step S2, the specific method is as follows:

[0039] S31: Soak the woven fabric in the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com