Adjustable sizing block for machine tool and assembly method thereof

A technology of adjusting pads and machine tools, which is applied in the direction of assembly machines, supporting machines, mechanical equipment, etc., can solve the problems of low precision, large friction, deflection, etc., and achieve the goal of reducing contact area, reducing friction, and avoiding contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

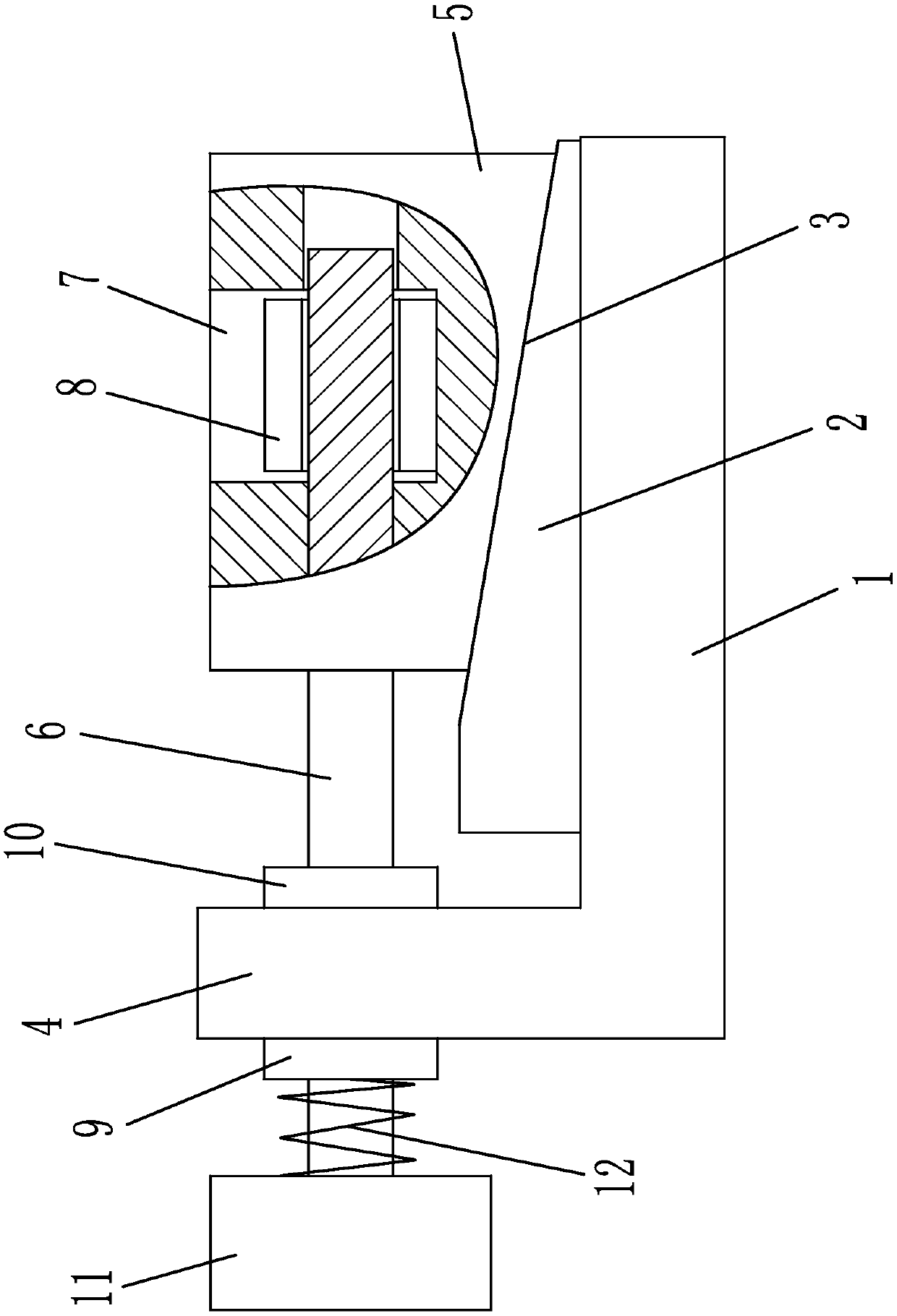

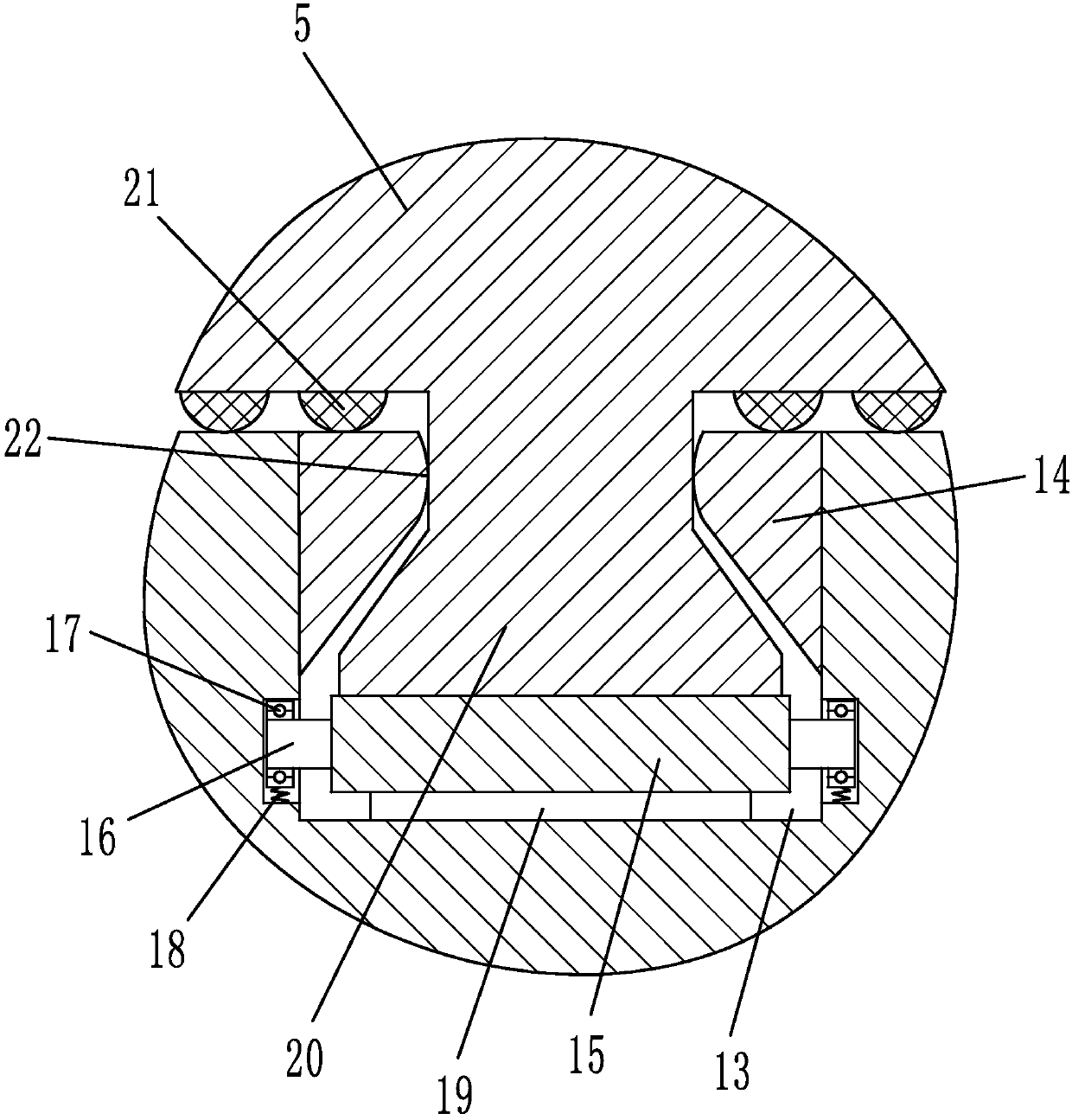

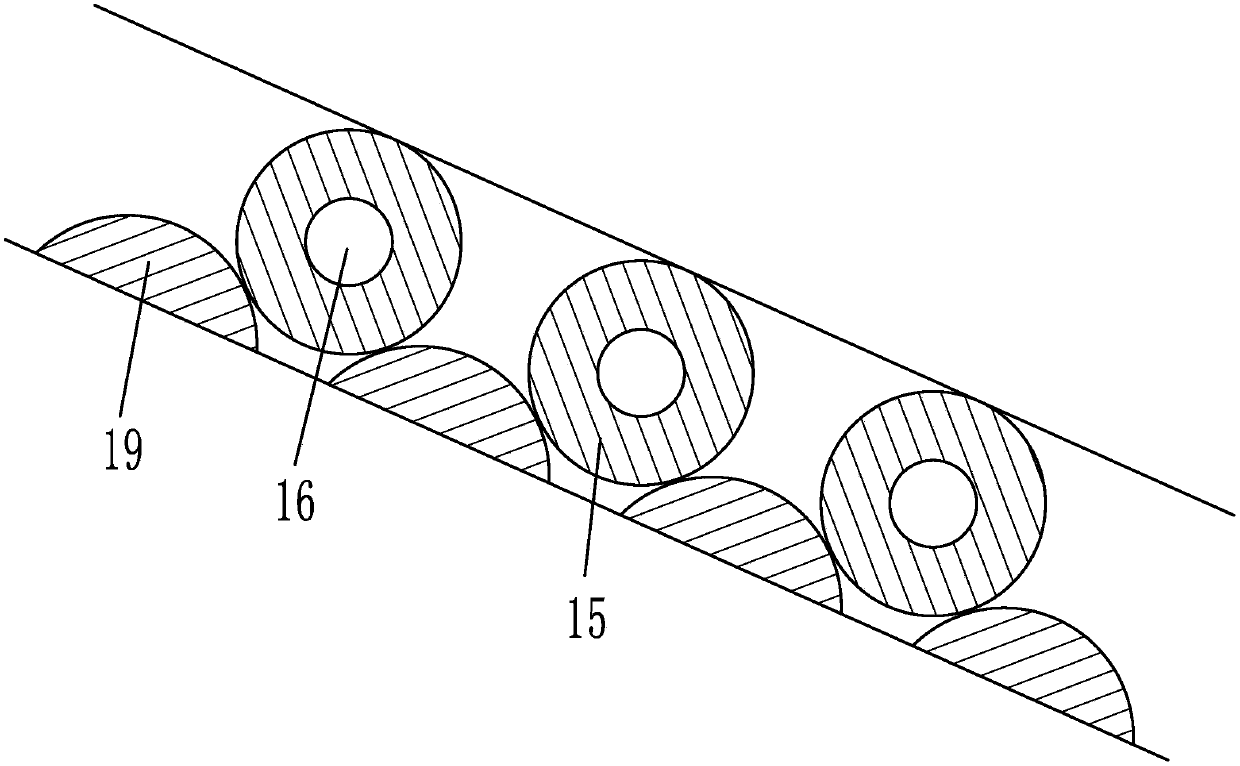

[0018] Embodiment 1: as figure 1 , 2 As shown in , 3 and 4, an adjusting pad iron for a machine tool includes a base 1 and a pad 5, one side of the base is vertically provided with a baffle 4, the baffle runs through the adjusting rod 6 horizontally, and the adjusting rod and the pad are threaded connection, the base is provided with a guide slide 2, the upper end of the guide slide is inclined with a guide slope 3, the spacer is located on the guide slope, the adjustment rod is set with a fixed stopper 10 and a limit stopper 9, and the fixed stopper The baffle and the limit stopper are respectively located on both sides of the baffle, and the baffle is provided with a card slot with an upper end opening. The baffle is located on the side of the baffle close to the spacer, the limit stop is located on the side of the baffle away from the spacer, the end of the adjustment rod far away from the spacer is provided with an adjustment rotor 11, and the adjustment rod is covered wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com