A kind of high-speed elevator wire rope and its preparation method and application

A technology of steel wire rope and steel wire, applied in the field of steel wire rope, can solve the problems of poor fatigue performance of steel wire rope, low oil content of steel wire rope, poor oil storage performance, etc., and achieve the effect of high oil content, high fatigue resistance and less grease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

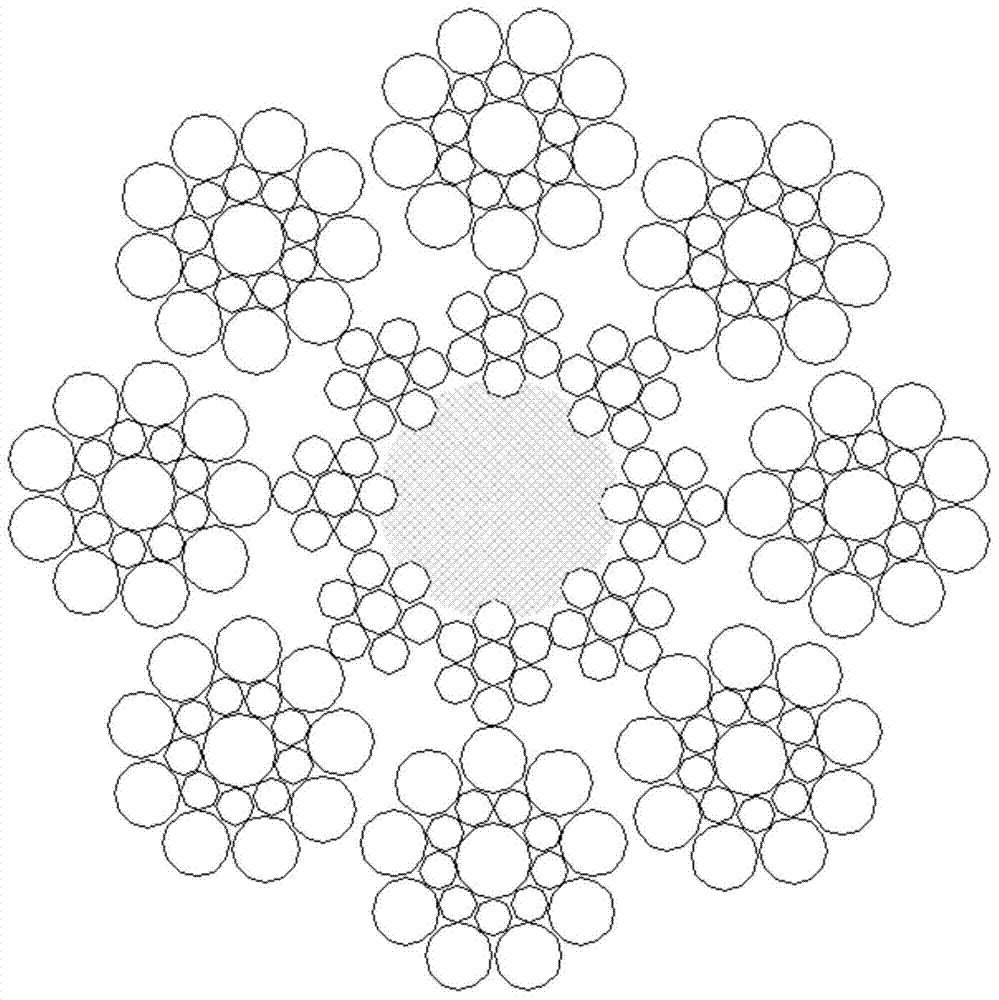

Image

Examples

Embodiment 1

[0048] The present embodiment provides the following preparation method for preparing elevator wire rope, and its specific steps are:

[0049] (1) Comb the sisal raw material into sisal yarn, then spin the sisal yarn into sisal yarn, wherein each sisal yarn contains 55 sisal yarns, and then 33wt% of the sisal yarn is soaked in grease, Make sisal rope, the diameter of this sisal rope is 3.3mm, the oil content of sisal rope is 25wt% of the whole sisal rope;

[0050] (2) Twisting 6 steel wires and twisting 1 central steel wire to make an inner layer strand, pour oil on the steel wire during the preparation process, so that the steel wire in the inner layer strand is wrapped by grease, wherein the grease content in the inner layer strand is 4wt% ;

[0051] (3) After twisting the sisal rope with inner layer strands, make it pass through molten grease to make a metal core, wherein the oil content of the metal core is 17wt%;

[0052] (4) Twisting 9 first steel wires and 9 second st...

Embodiment 2

[0056] Except that each sisal yarn in step (1) contains 57 sisal yarns, the sisal yarn of 35wt% is impregnated with grease, the diameter of the sisal rope made is 3mm, and the grease content of sisal rope is the whole sisal rope 23wt% of hemp rope; the grease content in the inner layer strand is 3wt% in the step (2); the oil content of the metal core is 15wt% in the step (3); the grease content in the outer layer strand is 1.5wt in the step (5) %, other steps and material consumption are the same as in Example 1.

[0057] The grease content of the finally prepared elevator steel wire rope is 10wt%, and its anti-fatigue performance is 32% higher than that of the elevator steel wire rope in CN102134811A.

Embodiment 3

[0059] Except that each sisal yarn in step (1) contains 60 sisal yarns, 30wt% sisal yarns are soaked in oil, the diameter of the sisal rope made is 3.5mm, and the oil content of the sisal rope is the whole The 22wt% of sisal rope; The grease content in the inner layer strand is 5wt% in the step (2); The oil content of the metal core is 20wt% in the step (3); The grease content in the outer layer strand is 2wt in the step (5) %, other steps and material consumption are the same as in Example 1.

[0060] The grease content of the finally prepared elevator steel wire rope is 15wt%, and its anti-fatigue performance is 34% higher than that of the elevator steel wire rope in CN102134811A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com