Handheld video acquisition device for detecting small bridges and culverts on roads

A collection device and culvert technology, which is applied in the field of hand-held video collection devices for detection of small highway bridges and culverts, can solve the problems of mechanical arm damage, high resource consumption, mechanical impact, etc., and achieve strong adaptability, high safety performance, energy saving and emission reduction effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

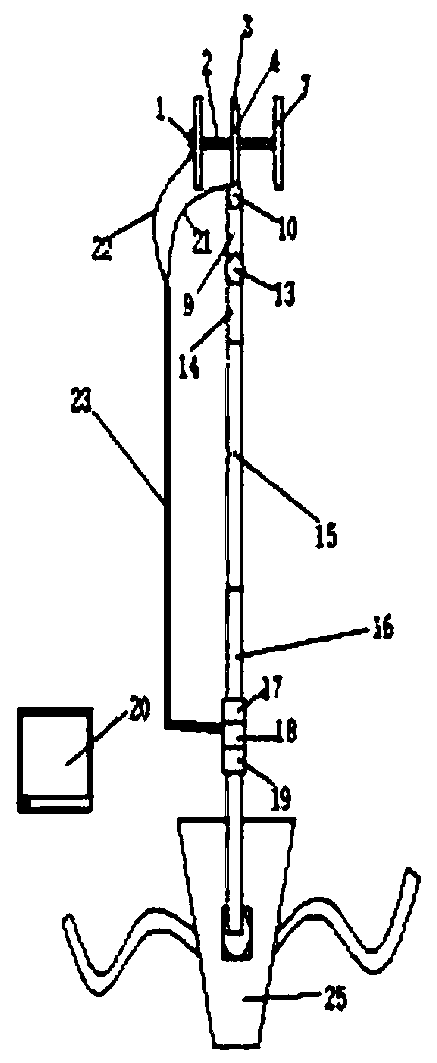

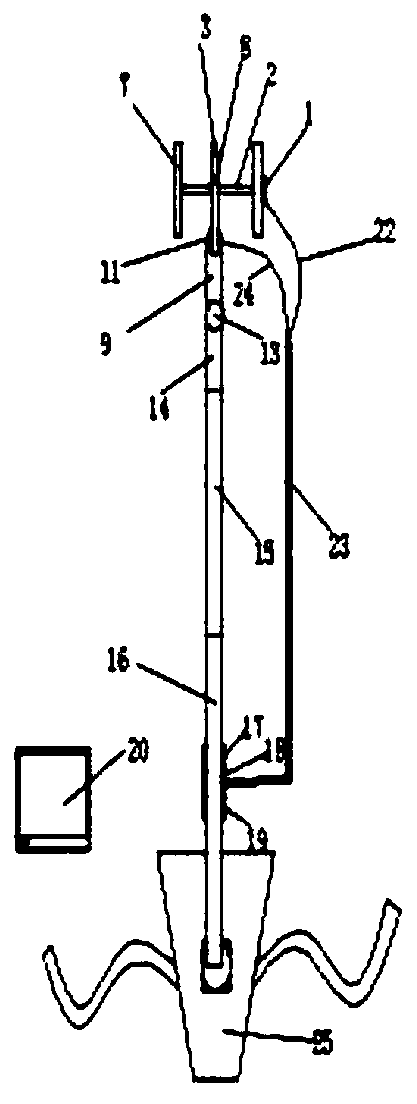

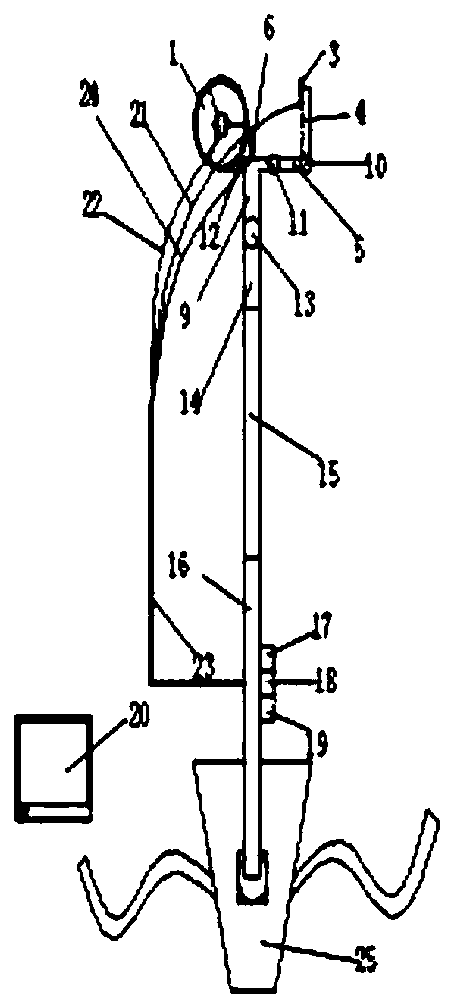

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0042] As shown in the figure, the small bridge and culvert superstructure quality inspection video image acquisition device of the present invention includes: wheel distance measuring encoder 1, pulley connecting shaft 2, camera 3 with lighting function, vertical camera bracket 4, horizontal Bracket 5, defect marking part 6, right pulley 7, wheel distance measuring encoder vertical bracket 8, first section detection rod 9, angle adjustment joint 10 at the front end of the horizontal bracket, angle adjustment joint 11 in the middle of the horizontal bracket, 360-degree vertical rotary joint 12, 360-degree vertical rotary joint on the detection rod 13, telescopic second longitudinal vertical measuring rod 14, telescopic third longitudinal vertical measuring rod 15, telescopic fourth longitudinal vertical measuring rod 16 , radio transmission box 17, operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com