High-temperature lava heat exchange system

A heat exchange system and high temperature technology, applied in the field of high temperature lava heat exchange system, can solve the problems of iron slag easily adhering to the roller, and achieve the effect of protecting the environment and saving heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

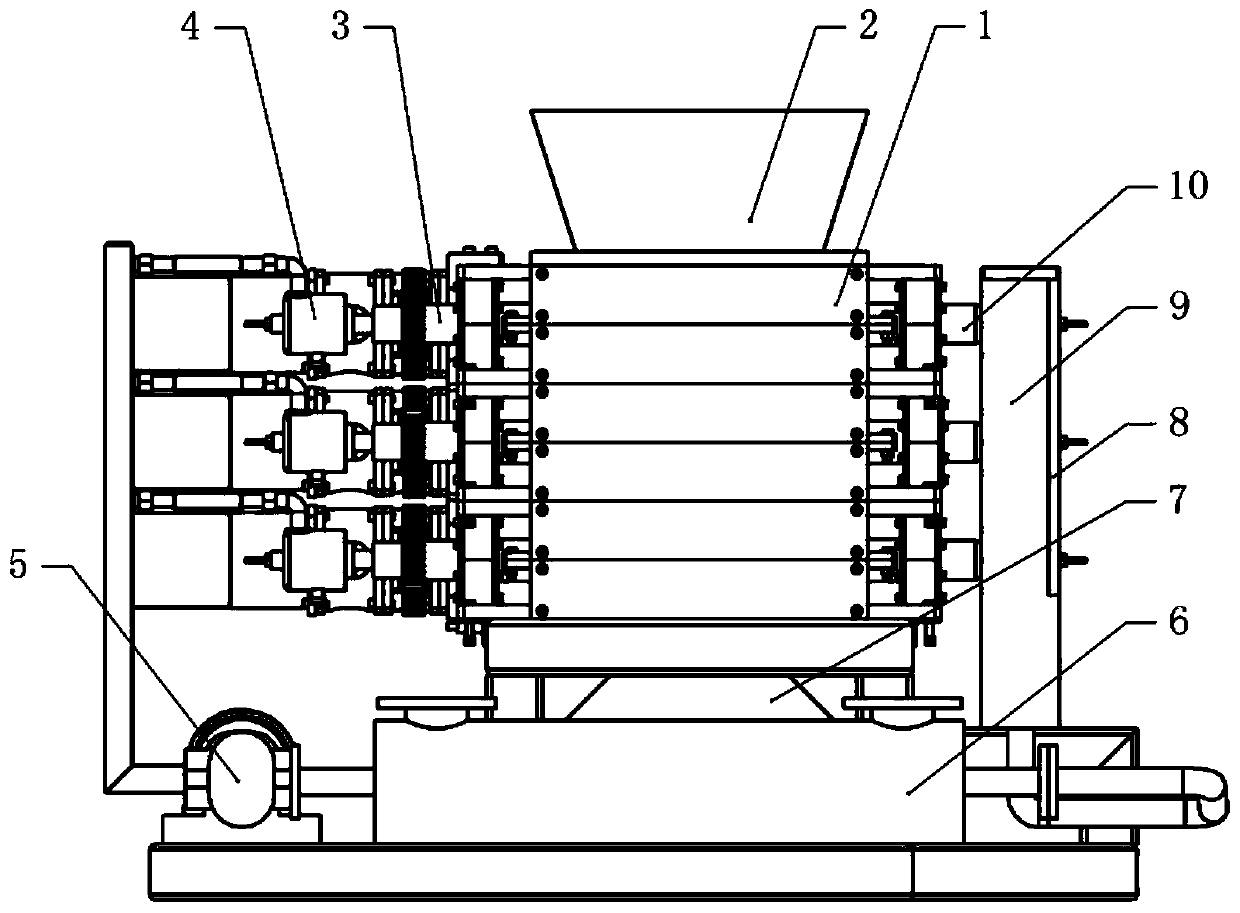

[0030] A high-temperature lava heat exchange system, basically as attached figure 1 As shown, it includes an exchange tank 1, a heat exchanger 6 and a pump for driving liquid metal circulation. The pump is either an electromagnetic pump or a mechanical pump 5, and the mechanical pump 5 is selected in this embodiment. Both the liquid inlet and the liquid outlet of the mechanical pump 5 are provided with electric heating rods (not shown) for heating the liquid metal, so that the electric heating rods and the mechanical pump 5 form an auxiliary heating system.

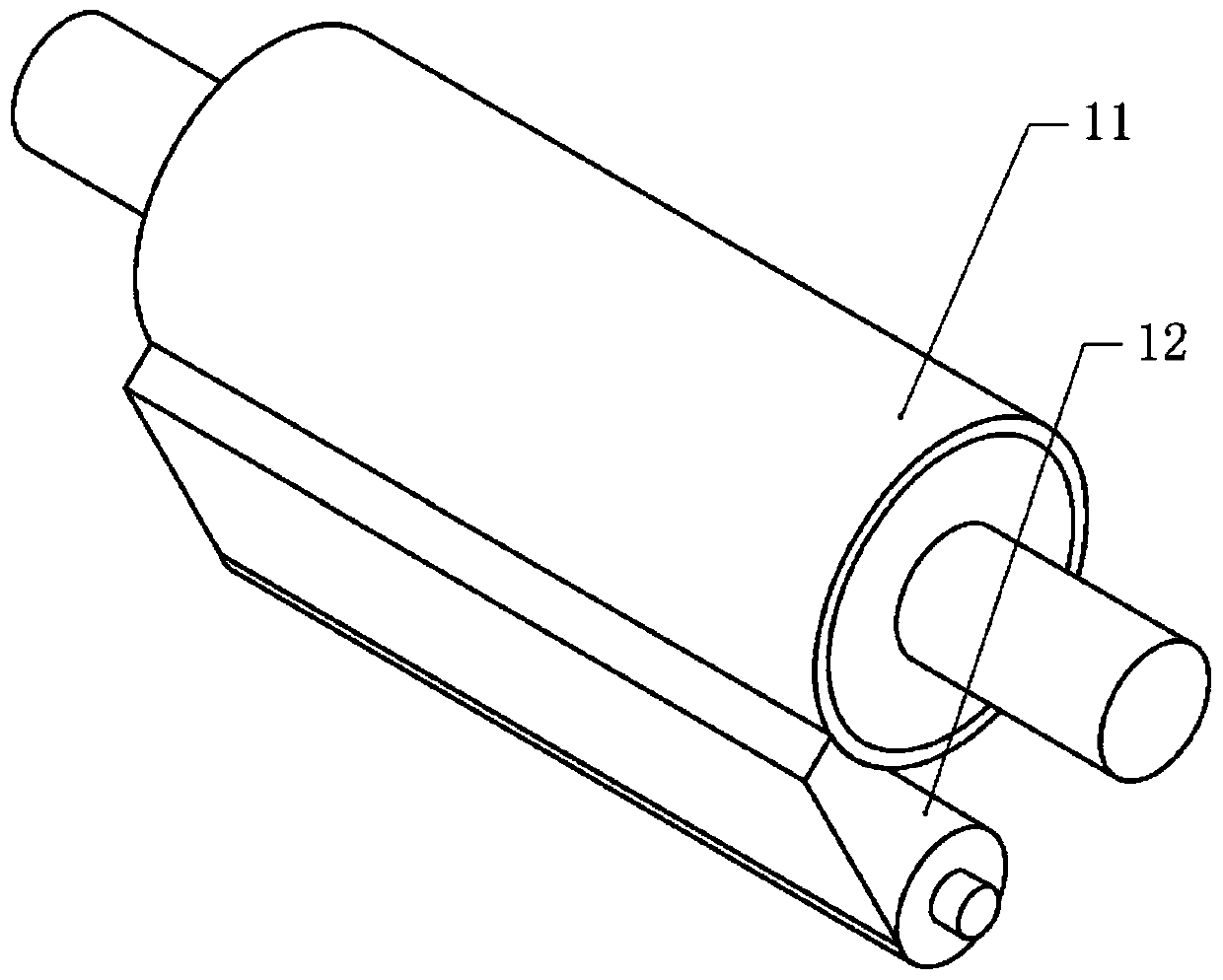

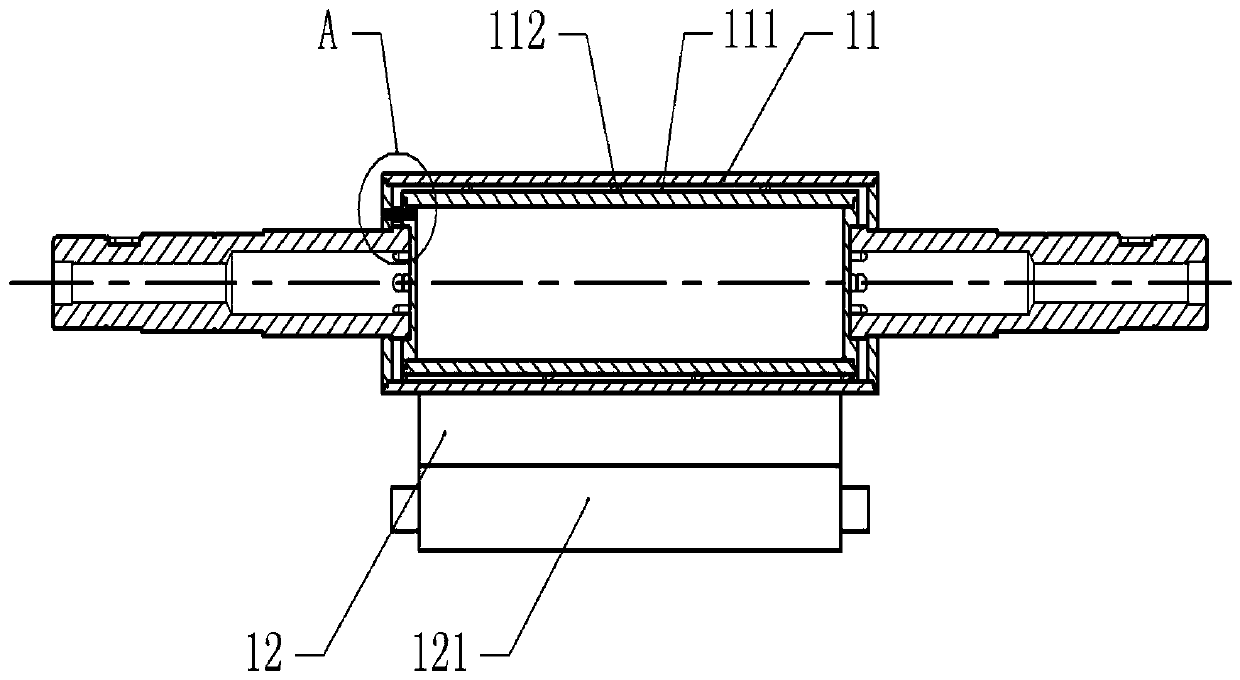

[0031] The upper part of the exchange box 1 is connected with a feed hopper 2, the feed hopper 2 is an inverted cone, the lower part of the exchange box 1 is connected with a discharge port 7, and at least one layer of rollers 11 is connected to the exchange box 1 in rotation. In this embodiment The middle roller 11 is one layer. as attached figure 2 , Attached Figure 3 and Attached Figure 4 As shown, the roller 11 i...

Embodiment 2

[0041] The difference from Embodiment 1 is that, as attached Figure 7 As shown, there are at least two scrapers 12, two of which are selected in this embodiment, and the lower part of the scraper 12 is provided with a rotating shaft 121, and the rotating shaft 121 is fixedly connected with the power part fixed on the exchange box 1, and the power part is a stepper Any one of the motor or the servo motor, the present embodiment selects a stepping motor (not shown in the figure). When the stepping motor is started, the stepping motor will drive the scraper 12 to rotate towards the outer cylinder, and the blade portion of the scraper 12 will be against the outer wall of the outer cylinder.

[0042] combined with Figure 8 As shown, the outer wall of the outer cylinder is provided with a number of chutes distributed in an annular array along its axial direction. The elastic part fixedly connected with the outer wall of the outer cylinder is any one of a tension spring, a compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com