Shipborne microplastic stratified sampling device

A sampling device and microplastic technology, applied in sampling devices and other directions, can solve problems such as manpower and material resources, and achieve the effects of saving time, improving sampling accuracy and fault tolerance rate, and high sampling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

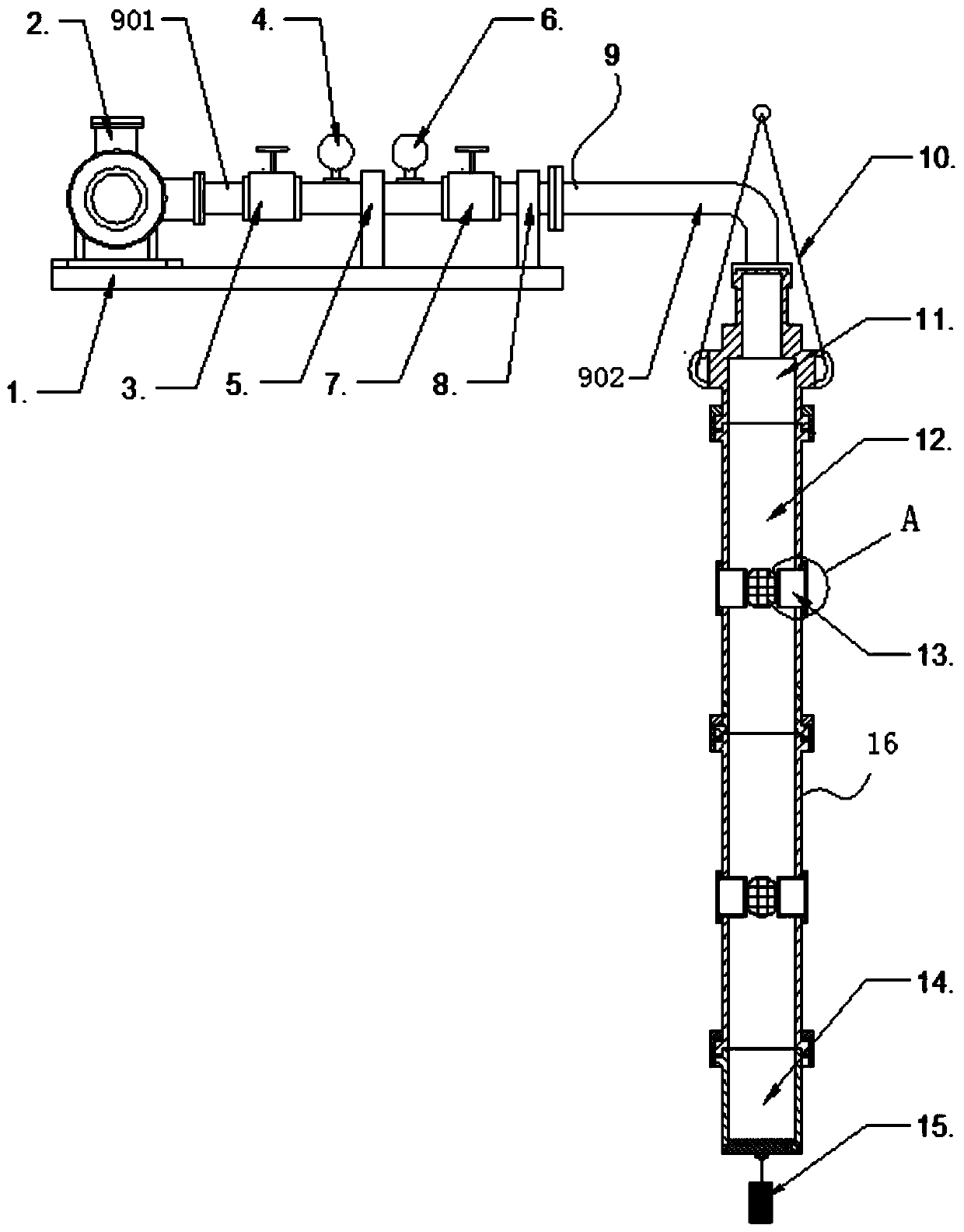

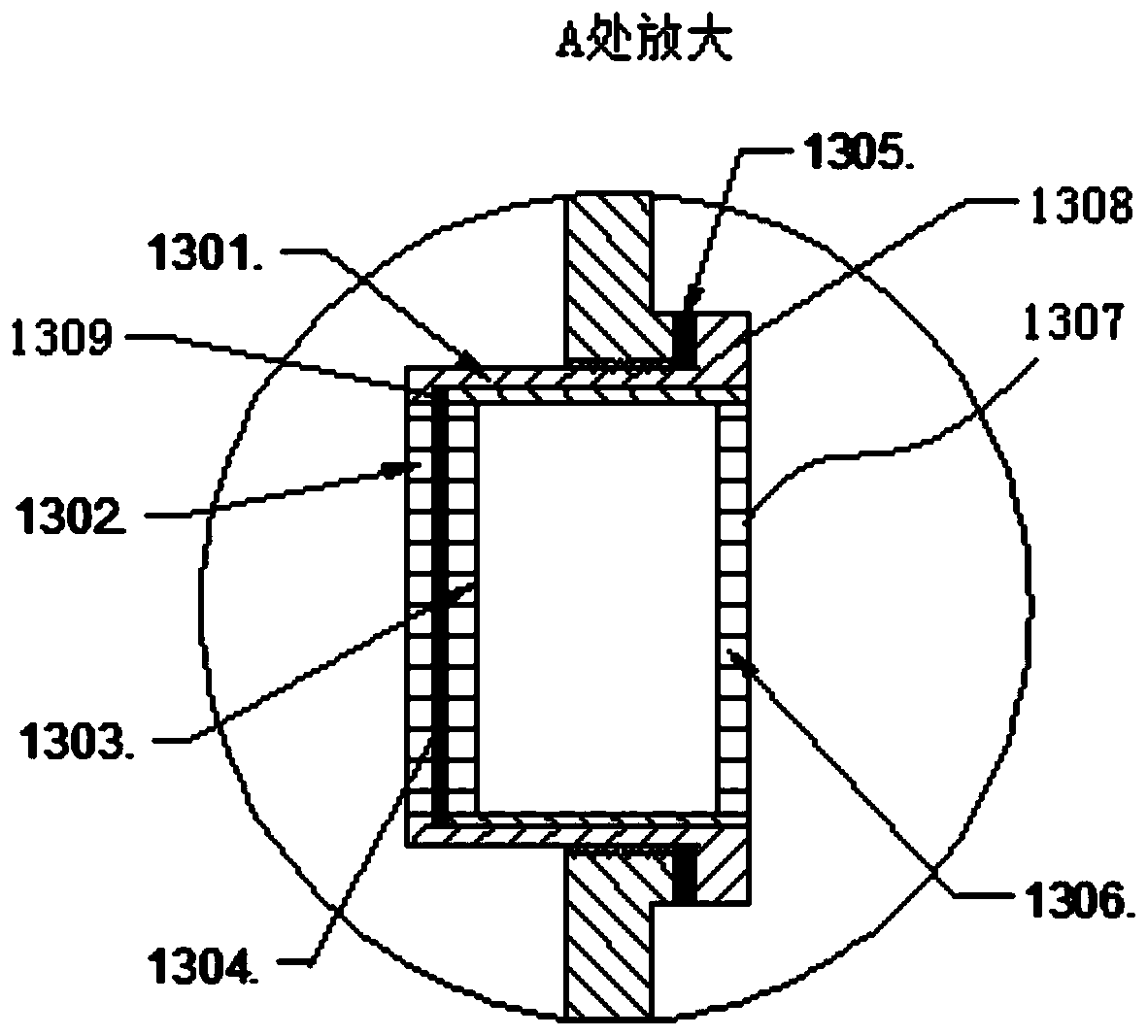

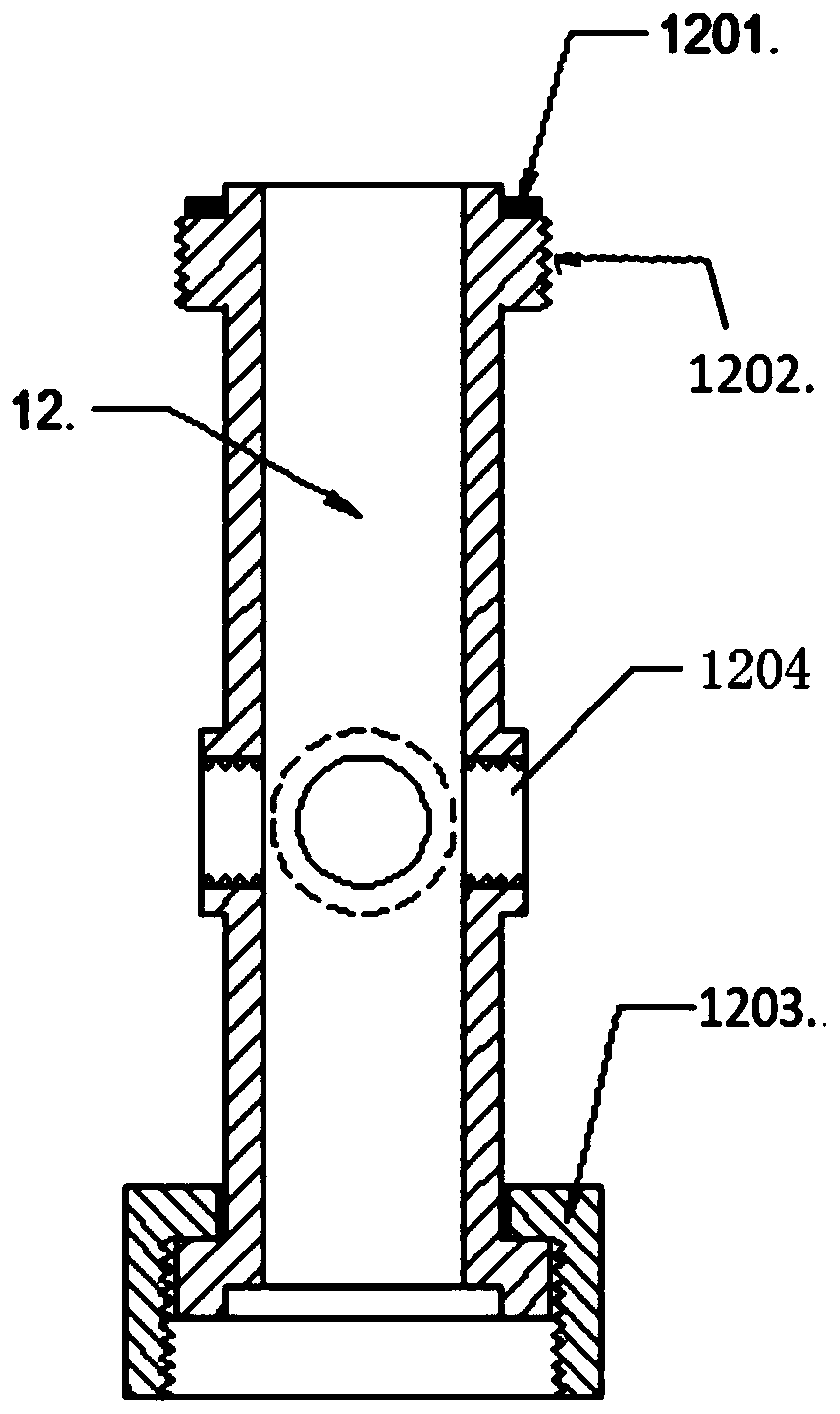

[0026] Such as Figure 1~4 As shown, the present invention includes a pumping device 2 and a sampler 16, the pumping device 2 is connected to the sampler 16 through a connecting pipeline 9, and a gate valve 3, a pressure gauge 4, Flow meter 6 and check valve 7, described sampler 16 comprises a plurality of sampling units 12 that are connected in sequence, and each sampling unit 12 corresponds to a sampling water layer, and described sampling unit 12 is provided with filter unit 13, as figure 2 As shown, the water filter unit 13 includes an inner coarse filter 1302, a fine filter 1304, and an outer coarse filter 1307 arranged sequentially from the inside to the outside, and the outer coarse filter 1307 includes a first coarse filter 1303 and a second coarse filter 1307. Two coarse filter screens 1306, and the fine filter part 1304 is arranged between the inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com