A method for extracting lithium from clay-type lithium ore

A technology for extracting lithium and lithium ore, which is applied in the field of lithium extraction, can solve problems such as high cost, large amount of slag in the lithium extraction process, and large pollution, and achieve the effects of easy handling, improved performance, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

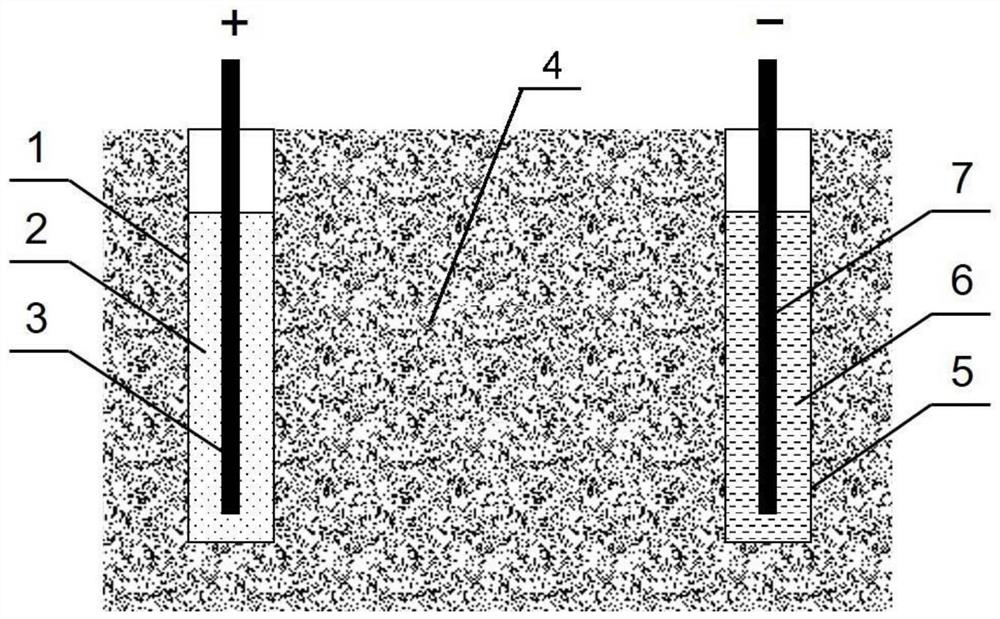

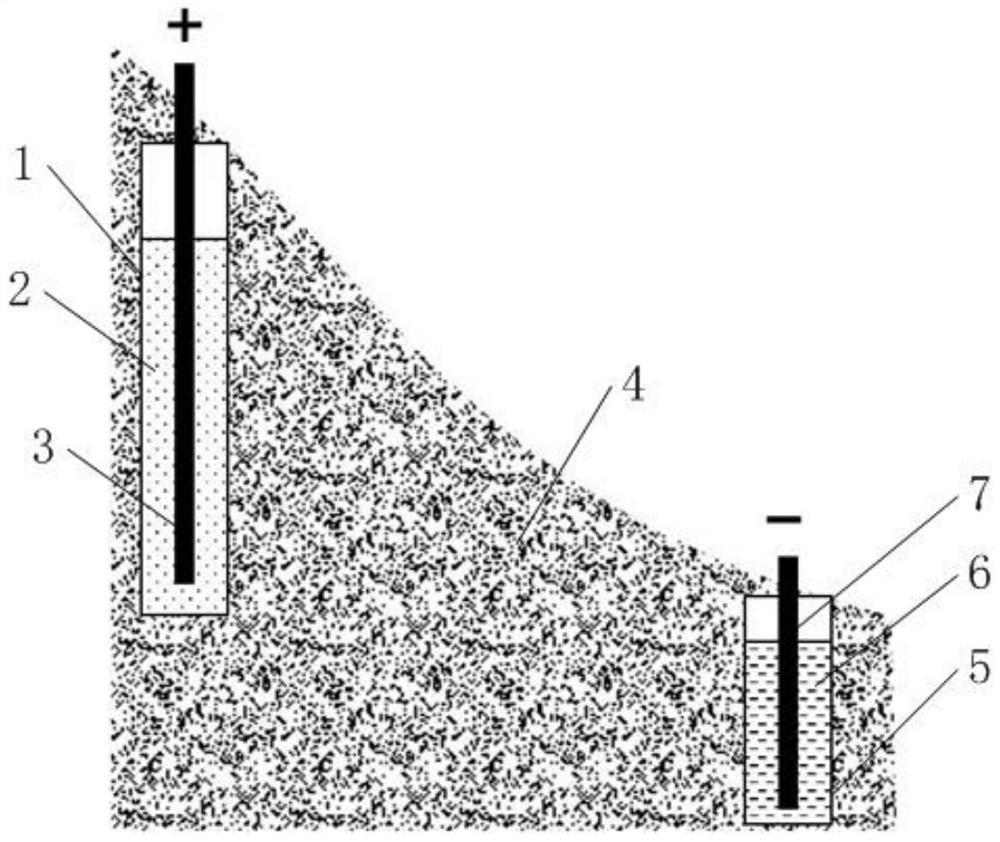

Method used

Image

Examples

Embodiment 1

[0050] Fill a 20cm-long circular tube with lithium-containing clay ore (containing Li 2 O content 0.62%), and the lithium-containing clay ore is compacted to a length of 10 cm, and the two ends of the lithium-containing clay ore in the circular tube are blocked with a sponge. Connect one end of the round tube to 1L containing 0.5mol / L Na 2 CO 3 +0.5mol / L NaHCO 3 The intercalation agent, which is inserted into the ruthenium-coated titanium plate anode, and the other end is connected to 1L containing 0.01mol / LNa 2 SO 4 The collector, into which the stainless steel cathode is inserted. A constant voltage of 40V (electric field strength of 2.0V / cm) was applied across the cathode and anode for electrolysis. Add Na to the intercalation agent and collector, respectively, during electrolysis 2 CO 3 and H 2 SO 4 , so that the pH of the two is controlled within the range of 6-13. After continuous electrolysis for 36 hours, the lithium concentration in the collector reached 865...

Embodiment 2

[0052] In the square electrolytic cell, two pieces of nylon cloth are used to vertically divide the cell area into three parts: the anode area, the middle area and the cathode area, and the middle area is filled with lithium-containing clay ore (containing Li 2 O content 0.44%), filled with 0.5L containing 0.005mol / L K in the anode area 2 SO 4 intercalation agent, and add 0.1mol MgCO 3 Powder, graphite plate anode inserted in the anode area; 0.5L containing 0.05mol / L KHCO in the cathode area 3 +0.05mol / L K 2 CO 3 +0.2mol / L KCl collector, insert graphite plate cathode in the cathode area. A constant voltage of 2.5V (electric field strength of 0.5V / cm) was applied across the cathode and anode for electrolysis. After continuous electrolysis for 50 hours, the lithium concentration in the collector reached 754mg / L.

Embodiment 3

[0054] Fill the 20cm long circular tube with 0.1mol / L CaCl 2 Lithium-containing clay minerals (containing Li 2 O content 0.35%), and the lithium-containing clay ore is compacted to a length of 10 cm, and the two ends of the lithium-containing clay ore in the circular tube are blocked with a sponge. Connect one end of the round tube to 1L containing 0.05mol / L Ca(HCO 3 ) 2 and 0.05mol / L CaCl 2 The intercalation agent, in which carbon fiber cloth anode is inserted, and the other end is connected to 1L collector containing 0.01mol / L NaCl, in which stainless steel cathode is inserted. A constant voltage of 2V (electric field strength of 0.1V / cm) was applied across the cathode and anode for electrolysis. After 120 hours of electrolysis, the lithium concentration in the collector reached 109mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com