Evaluation method of polypropylene metallocene catalyst

A metallocene catalyst and evaluation method technology, which is applied in the evaluation field of polypropylene metallocene catalyst, can solve problems such as lack of evaluation methods, and achieve the effect of avoiding amplification difficulties or even failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

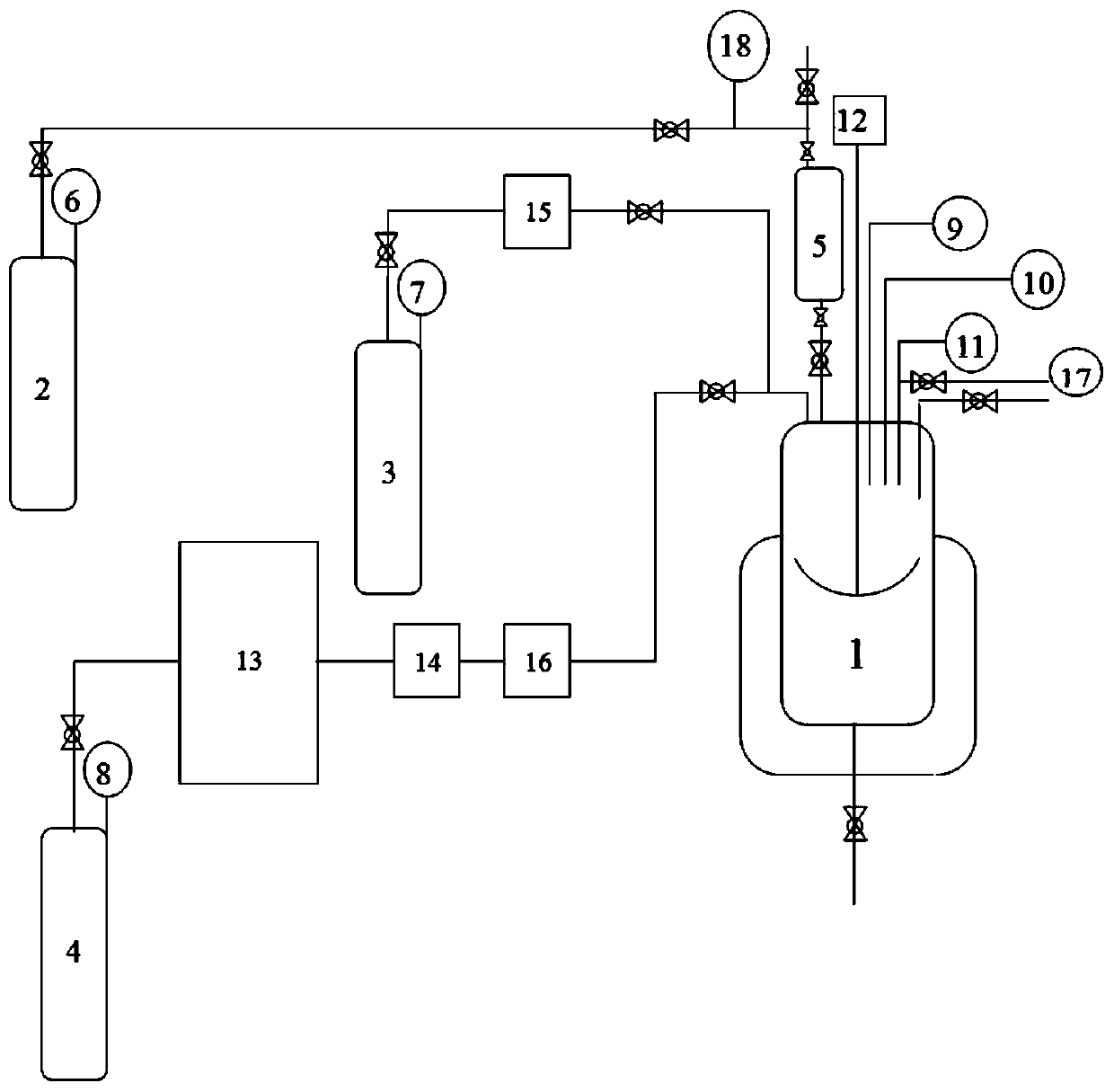

[0046]Heat a 5L stainless steel high-pressure reactor with hot water to 80°C, replace it with nitrogen three times, use a vacuum device to evacuate the reactor to 5Pa, and replace reactor 1 with propylene for three times. Add 0.1 g of atmospheric pressure hydrogen into the reaction kettle, and then add 1.6 kg of liquid propylene while stirring. The temperature of the reaction kettle was raised to 35° C., and the pressure therein was 1.5-1.7 MPa at this time. In the glove box, 90 mg of the metallocene catalyst to be tested were charged to the high pressure feeder. Add the metallocene catalyst in the high-pressure feeding device into the reactor, react at 35° C. for 20 minutes, then raise the temperature in the reactor to 60° C., and carry out polymerization at this temperature for 2 hours. After the polymerization is completed, the temperature is lowered, and the obtained polypropylene product is extruded, and its yield is measured. The catalyst evaluation results are shown i...

Embodiment 2

[0050] Heat a 5L stainless steel high-pressure reactor with hot water to 80°C, replace it with nitrogen three times, use a vacuum device to evacuate the reactor to 5Pa, and replace reactor 1 with propylene for three times. Add 0.1 g of atmospheric pressure hydrogen into the reaction kettle, and then add 1.6 kg of liquid propylene while stirring. The temperature of the reaction kettle was raised to 35° C., and the pressure therein was 1.5-1.7 MPa at this time. In the glove box, 90 mg of the metallocene catalyst to be tested were charged to the high pressure feeder. Add the metallocene catalyst in the high-pressure feeding device into the reactor, react at 35° C. for 20 minutes, then raise the temperature in the reactor to 70° C., and carry out polymerization at this temperature for 2 hours. After the polymerization is completed, the temperature is lowered, and the obtained polypropylene product is extruded, and its yield is measured. The catalyst evaluation results are shown ...

Embodiment 3

[0054] Heat a 5L stainless steel high-pressure reactor with hot water to 80°C, replace it with nitrogen three times, use a vacuum device to evacuate the reactor to 5Pa, and replace reactor 1 with propylene for three times. Add 0.1 g of atmospheric pressure hydrogen into the reaction kettle, and then add 1.6 kg of liquid propylene while stirring. The temperature of the reaction kettle was raised to 35° C., and the pressure therein was 1.5-1.7 MPa at this time. In the glove box, 90 mg of the metallocene catalyst to be tested were charged to the high pressure feeder. Add the metallocene catalyst in the high-pressure feeding device into the reactor, react at 35° C. for 20 minutes, then raise the temperature in the reactor to 80° C., and carry out polymerization at this temperature for 2 hours. After the polymerization is completed, the temperature is lowered, and the obtained polypropylene product is extruded, and its yield is measured. The catalyst evaluation results are shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com