A fabricated building design device and method

A kind of architectural design and assembly technology, which is applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of long time-consuming, affecting the construction process, and a large amount of time for the model, and achieve the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

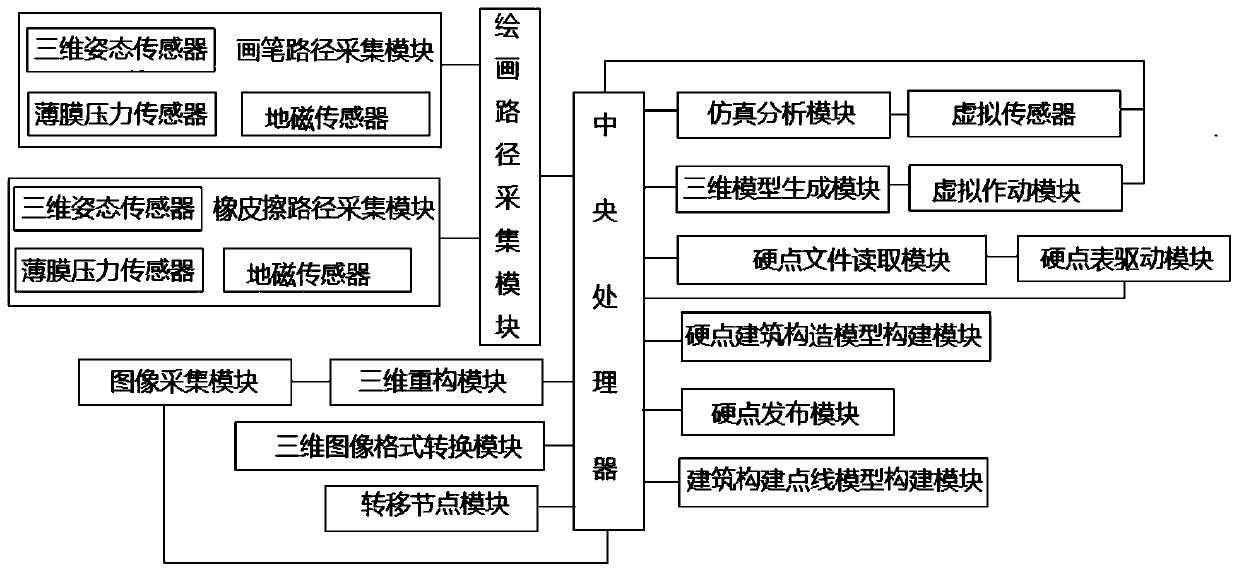

Image

Examples

Embodiment 1

[0070] A prefabricated building design device and method, realized based on the above-mentioned design device, comprising the following steps:

[0071] 1. Realize the acquisition of the brush path and the eraser path through the three-dimensional attitude sensor and the geomagnetic sensor, and generate the final drawing path based on the brush path and the eraser path;

[0072] 2. According to the stability parameter requirements of the prefabricated building, use ADAMS to establish the 3D model of the target prefabricated building, and obtain the ADAMS hard point file, which at least includes the location information of each hard point of the prefabricated building;

[0073] 3. Read the coordinate values of each hard point in the hard point file to form a modifiable hard point table;

[0074] 4. According to the hard point table, establish a hard point building structure model, which includes all hard point coordinates;

[0075] 5. Carry out parameterization processing on ...

Embodiment 2

[0080] A kind of prefabricated building design method based on above-mentioned design device, comprises the following steps:

[0081] 1. Collect images of drawings / models / target buildings through the image acquisition module;

[0082] 2. Acquire the depth image of the collected image data based on the kinect depth sensor through the 3D reconstruction module, triangulate the obtained depth image, and then fuse all the triangulated depth images in the scale space to construct a layered structure To the distance field, apply the overall triangulation algorithm to all voxels in the distance field to generate a convex hull covering all voxels, and use the Marching Tetrahedra algorithm to construct the isosurface to complete the reconstruction of the 3D image;

[0083] 3. Based on the 3D image format conversion module, convert the reconstructed 3D image into a format that can be recognized by the ADAMS software, and import it into ADAMS to obtain the ADAMS hard point file, which at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com