A rotary machine fault feature extraction method based on vibration signal correlation analysis

A correlation analysis and vibration signal technology, applied in computer parts, measuring devices, instruments, etc., can solve the problem of difficulty in extracting fault features of rotating machinery and equipment, and achieve the effect of simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

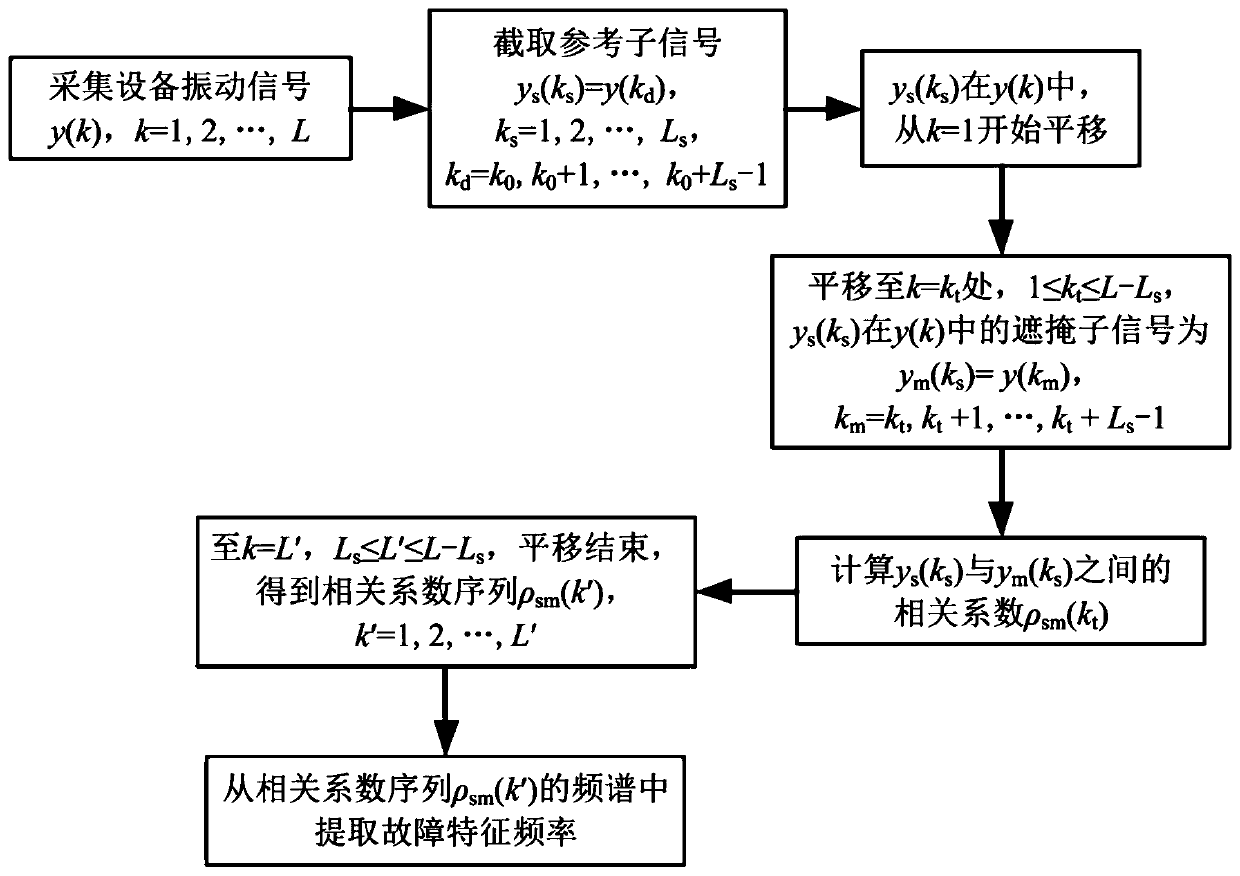

[0025] refer to figure 1 , a rotating machinery fault feature extraction method based on vibration signal correlation analysis, including the following steps:

[0026] (1) Collect a group of vibration signals y(k) with a length of L on the rotating mechanical equipment, where k=1, 2,...,L;

[0027] (2) Randomly select a time point k=k in the vibration signal y(k) 0 , starting from this point to intercept a section of length L s The reference sub-signal y of s (k s ), where L s s =1,2,...,L s , and the reference sub-signal y s (k s )=y(k d ), where k d =k 0 ,k 0 +1,...,k 0 +L s -1;

[0028] (3) Let the reference sub-signal y s (k s ) starts from the initial time point k=1 of the vibration signal y(k), and translates point by point along the time axis direction where k increases;

[0029] (4) At time point k=k t where 1≤k t ≤L-L s , the reference sub-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com