Method for extracting folic acid from soybean

A folic acid and soybean technology, applied in organic chemistry, color/spectral characteristic measurement, etc., can solve problems such as low sensitivity, interference with folic acid determination, difficulty in folic acid quantification, etc., and achieve the effect of reducing experimental errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Soybean sample preparation

[0032] The soybean seeds were crushed to obtain soybean powder, and 0.2 g of soybean powder was weighed and placed in a 2 mL AXYGEN EP tube, repeated three times. Add 750μL of folic acid extraction buffer (50mM phosphate buffer, pH=6.5, 1% sodium ascorbate, 0.1% 2-mercaptoethanol) to each sample, incubate at 95℃ for 15min and cool on ice, then add 5mm steel balls , Grind the sample in a tissue grinder (rotating speed is 1400rpm, time is 5min). All samples need to be protected from light during grinding.

Embodiment 2

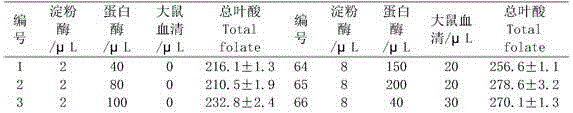

[0033] Example 2 Soybean Folic Acid Extraction

[0034] Add 8μL of α-amylase and 750μL of folic acid extraction buffer to the sample homogenate to avoid stickiness, place at room temperature for 10 minutes, add 100μL of protease, and incubate at 37°C for 1hr; boil the above mixture at 100°C for 10 minutes to stop the enzyme action, and quickly cool on ice for 10 minutes ; Centrifuge for 10 min at 4℃ and 14000rpm; aspirate the supernatant, add 10μL of rat serum to the supernatant according to the volume of 2%, mix well, incubate at 37℃ for 2h; boil and inactivate at 100℃ for 10min, on ice Cool quickly for 10 minutes; centrifuge for 15 minutes at 4°C and 14000 rpm; pipette the supernatant into a sterile tube for direct determination or freeze storage at -80°C. The sample extraction process needs to be protected from light.

Embodiment 3

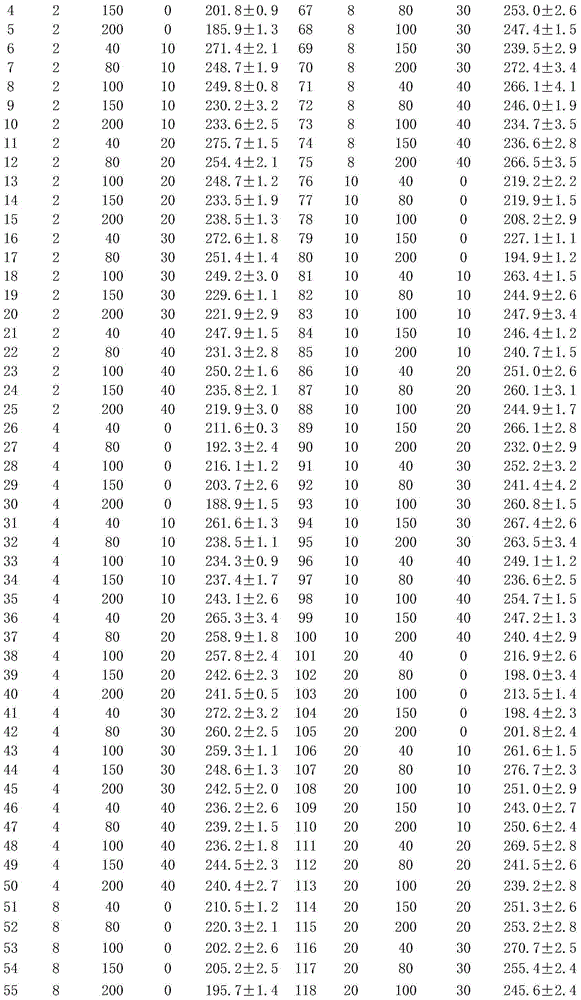

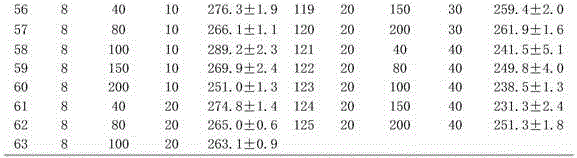

[0035] Example 3 Microbial detection method of soybean folic acid

[0036] (1) Reagent preparation

[0037] Lactobacillus liquid culture medium: 4.85g lactic acid bacteria culture medium is added to 100mL water, and sterilized at 121°C for 15min.

[0038] Low folic acid medium: Weigh 4.7g folic acid medium powder, 0.03g ascorbic acid, and 0.3mL folic acid standard stock solution, add water to dissolve and dilute to 100mL, and sterilize through 0.22μm filter membrane for use.

[0039] Analysis buffer: Weigh Na 2 HPO 4 .2H 2 O 0.38g, NaH 2 PO 4 0.93g, 1g ascorbic acid, dissolved in water and dilute to 100mL, sterilized through 0.22μm filter membrane for use.

[0040] Folic acid culture medium: Weigh 9.4g of folic acid culture medium powder, add water to dissolve and make the volume to 100mL, boil for 5min, and sterilize through 0.22μm filter membrane for use.

[0041] (2) Preparation of folic acid standard samples

[0042] Weigh 28mg of folic acid in 4mL of 5% K 2 HPO 4 The solution is then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com