heat exchanger

A heat exchanger and edge technology, applied in heat exchange equipment, heat exchangers, indirect heat exchangers, etc., can solve problems such as failure to comply with dimensional and geometric tolerances, production difficulties, and loss of mechanical energy of the first fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

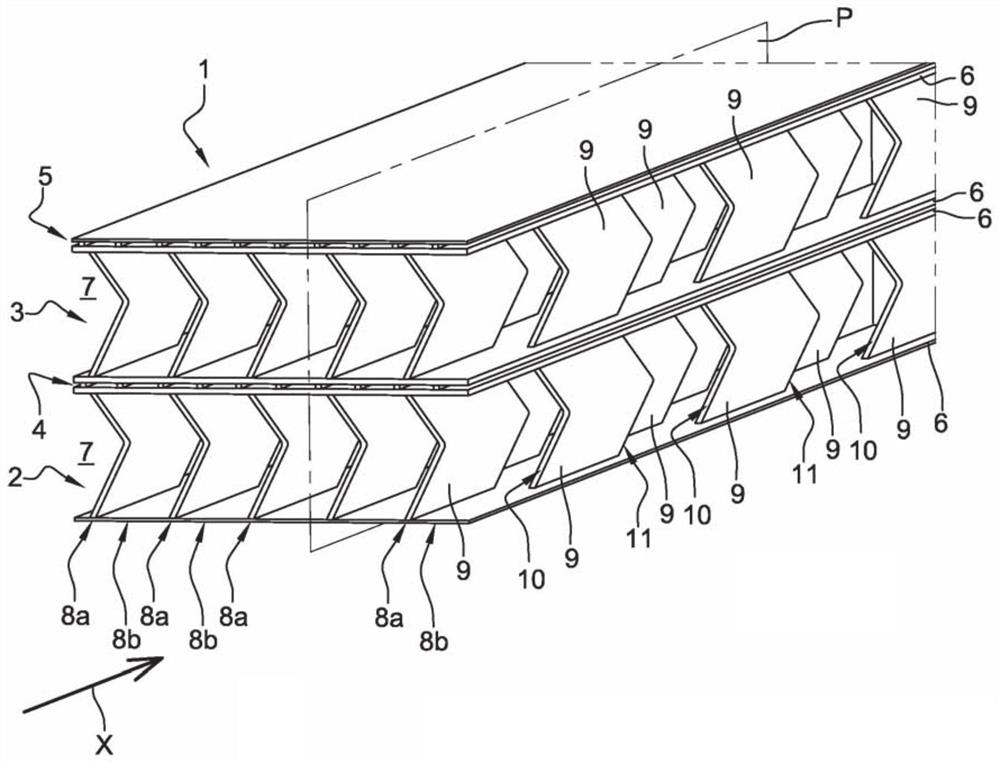

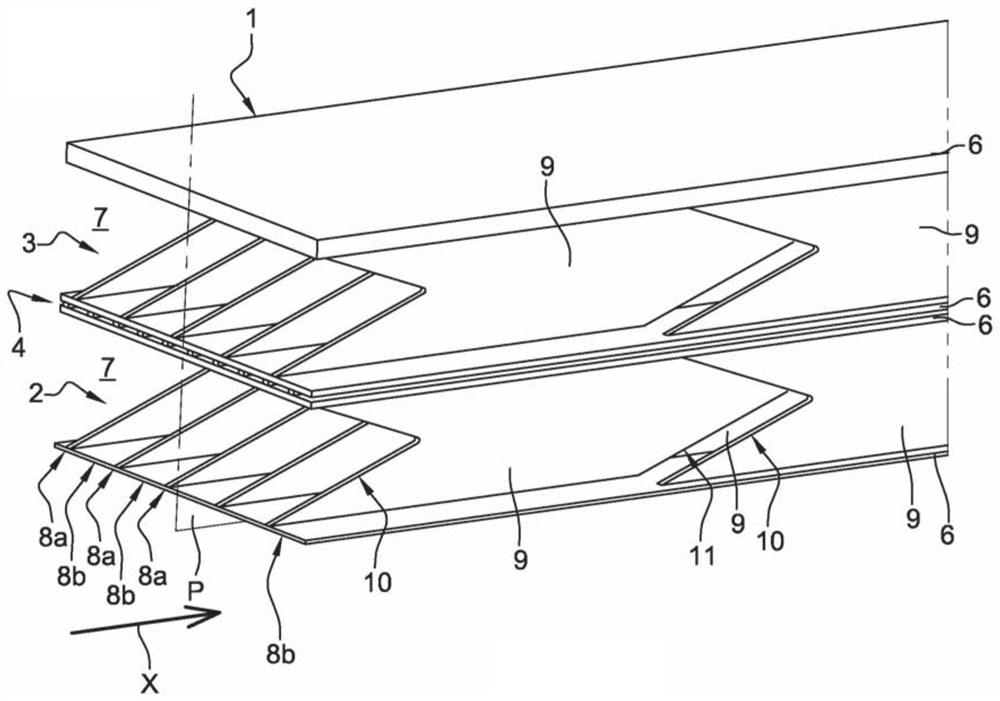

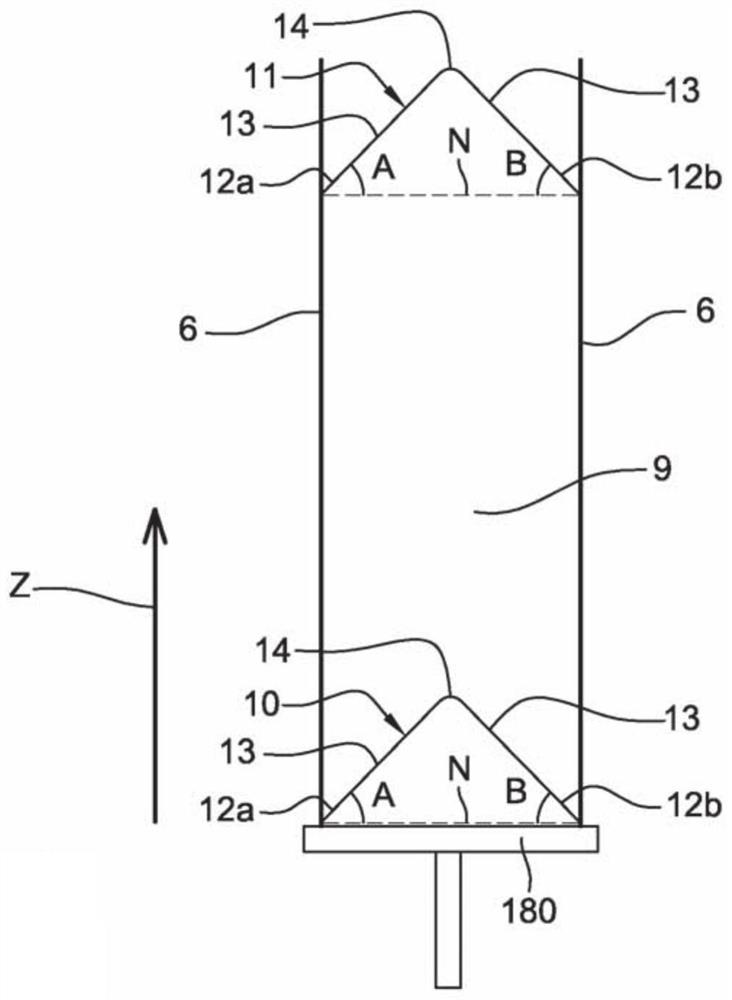

[0037] exist figure 1 and figure 2 , a heat exchanger 1 between a first fluid (eg hot exhaust gas) and a second fluid (eg air) flowing in a longitudinal direction X is shown.

[0038] More specifically, the exchanger 1 is staged, ie a first stage 2 and a second stage 3 for circulating a first fluid. A first path 4 for circulating the second fluid is arranged between the first stage 2 and the second stage 3 (interstage circulation path). A second path 5 for circulating the second fluid ( figure 2 not shown in ) is arranged on the free side of the second stage 3 .

[0039] The example shown is by no means limiting, the exchanger 1 may have N stages, each stage defines a channel for circulating a first fluid, and two adjacent stages are used for circulating a second fluid, as required path separated.

[0040] It has to be noted that the flow of the first fluid along the longitudinal direction X can be from upstream to downstream (such as figure 1 shown) or from downstream...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com