Semi-automatic straightening method for high-purity aluminum rotating target welding end

A technology for welding ends and rotating targets, which is applied in forming tools, manufacturing tools, metal processing, etc., and can solve the problem of skewing or bending deformation of high-purity target tubes and alloy ends, straightness not meeting the requirements for use, high-purity Target tube extrusion deformation and other problems, to achieve high yield, fast response, good alignment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

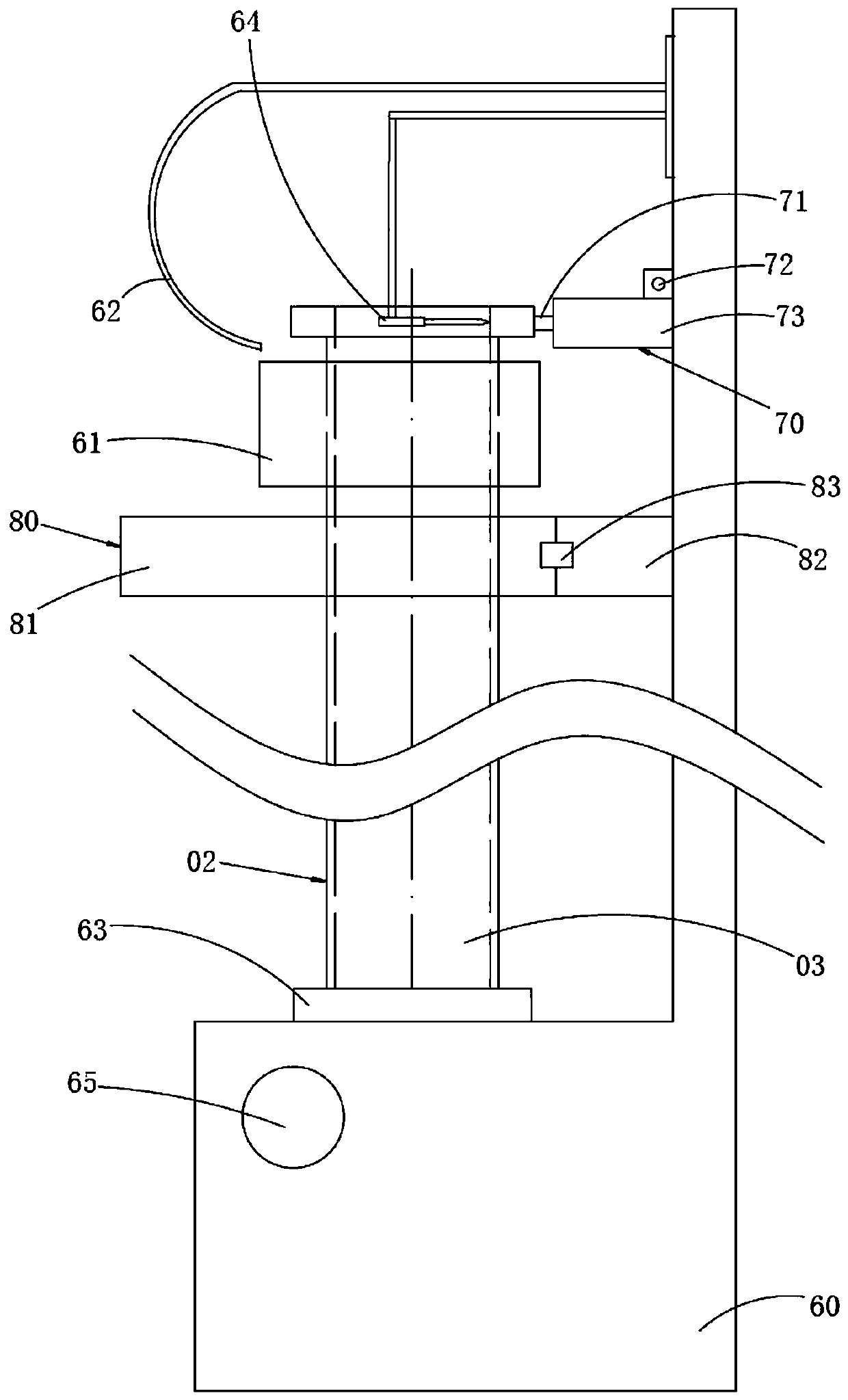

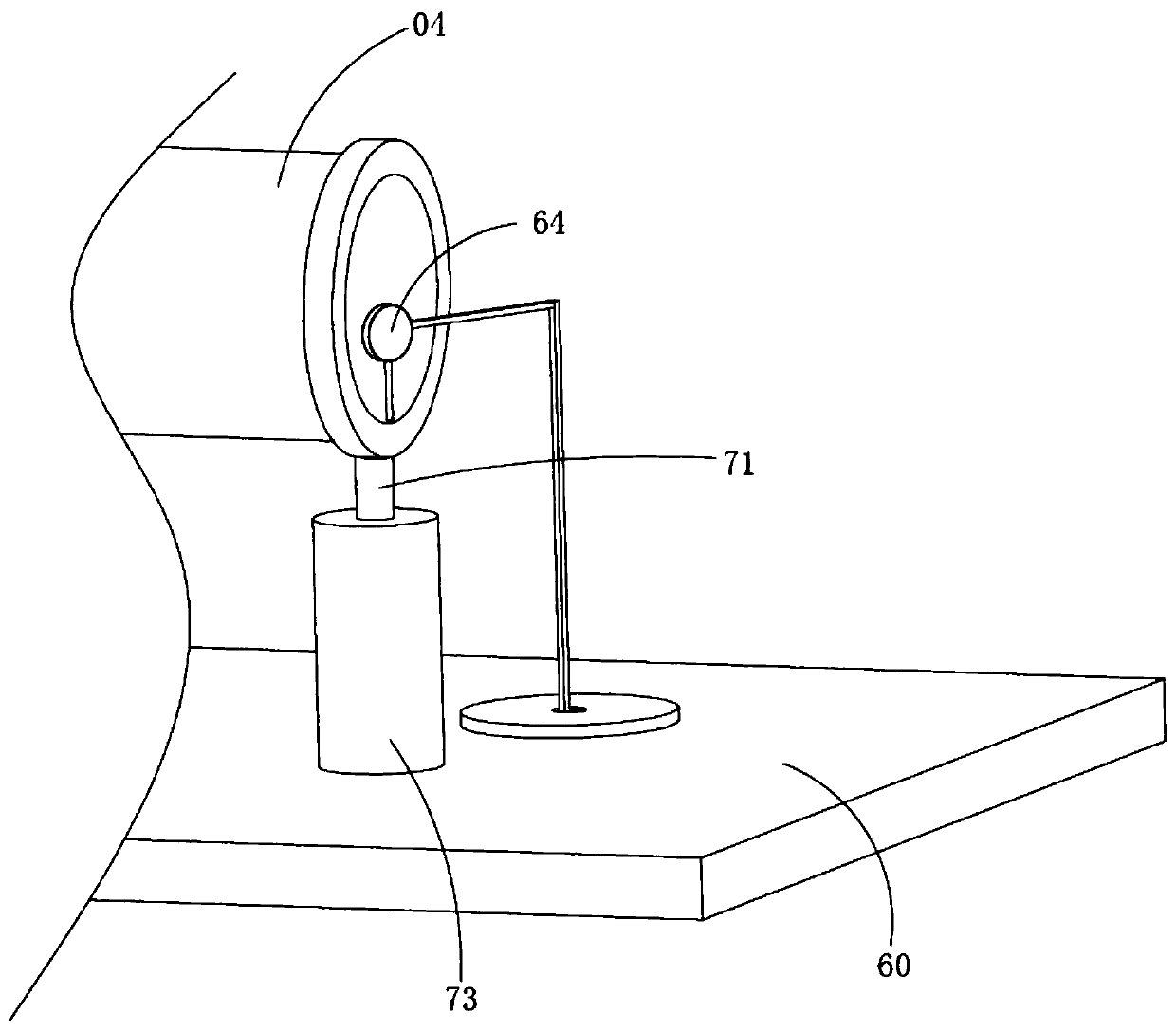

[0047] A semi-automatic straightening method for high-purity aluminum rotary target welding ends, such as Figure 1 to Figure 3 as shown,

[0048] 1) In the preparation step, the high-purity aluminum rotating target 02 is hoisted and moved to the straightening equipment, and placed on the frame 60 of the straightening equipment.

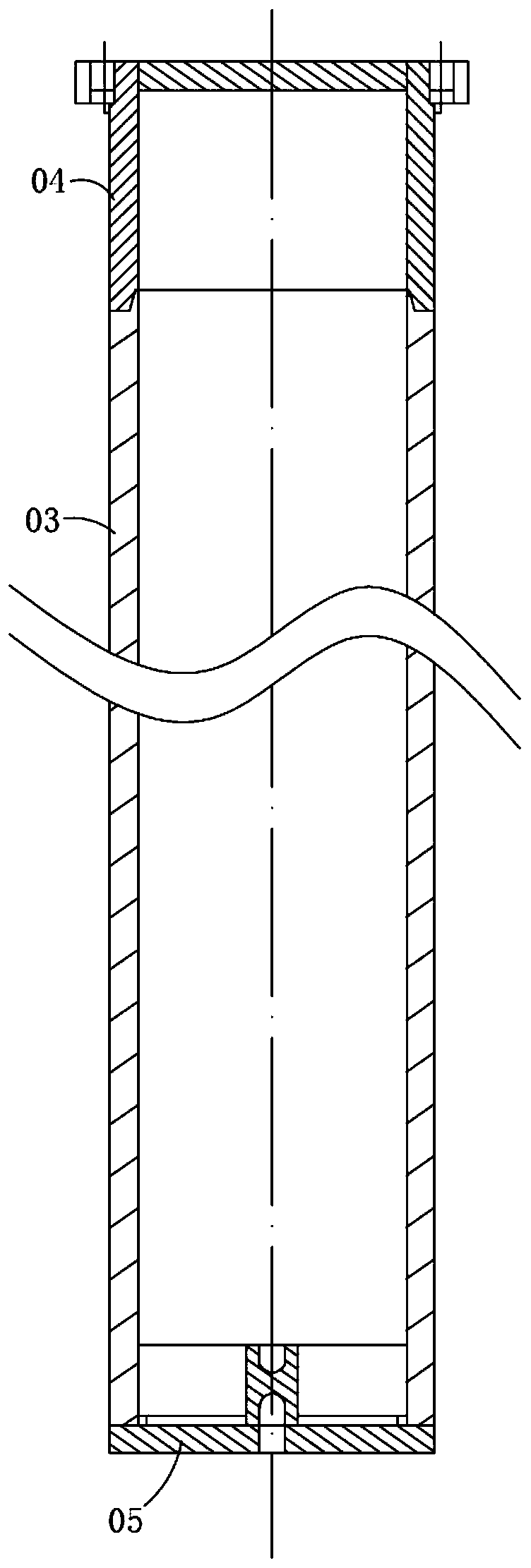

[0049] Among them, the high-purity aluminum rotating target 02 includes high-purity aluminum target tube 03, aluminum alloy end cap 04 and aluminum alloy end cap 05, and the aluminum alloy end cap 04 and aluminum alloy end cap 05 are connected with the high-purity aluminum target tube 03 respectively. Both ends are welded and installed. There is a welding port at the connection between the aluminum alloy terminal 04 and the high-purity aluminum target tube 03. A flange is fixed on the outer wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com