Oil seal bolt processing die

A technology for processing molds and bolts, applied in the field of oil seal bolt processing molds, can solve the problems of inaccurate stamping and stamping dislocation, and achieve the effect of reducing friction and enhancing sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

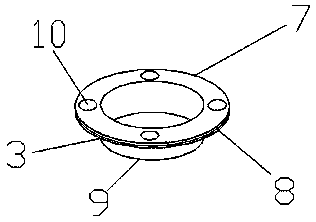

[0018] As a preferred embodiment of the present invention, there are multiple fixing holes 10 and screw holes, and the size and structure of the fixing holes 10 and the screw holes are the same. Multiple identical screw holes and fixing holes ensure the stability and consistency of the connection.

[0019] As a preferred embodiment of the present invention, the sealing ring 7 and the limiting ring 9 are both made of rubber material and integrally formed by fusion. The rubber material has a certain degree of flexibility and has the effect of an oil seal.

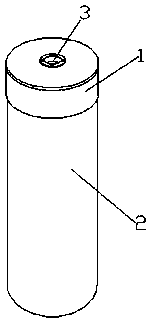

[0020] As a preferred embodiment of the present invention, both the forging body 1 and the fixing pin 2 are made of titanium alloy. Through the composition of titanium alloy material, it can withstand strong punching force and improve the life of the mold.

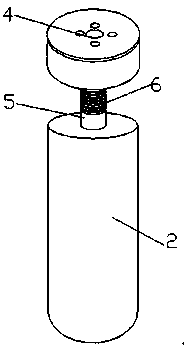

[0021] As a preferred embodiment of the present invention, the locking thread 6 at one end of the connecting column 5 matches the thread structure of the locking hole a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com