Novel automatic robot gluing detection system

A robotic system and gluing detection technology, applied in the direction of instruments, coatings, measuring devices, etc., can solve the problems of small deviation of gluing trajectory that cannot be visually inspected, heavy workload of gluing trajectory adjustment, complex manipulator system, etc., to achieve The effect of reducing quality risk, improving detection ability, and reducing leakage risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

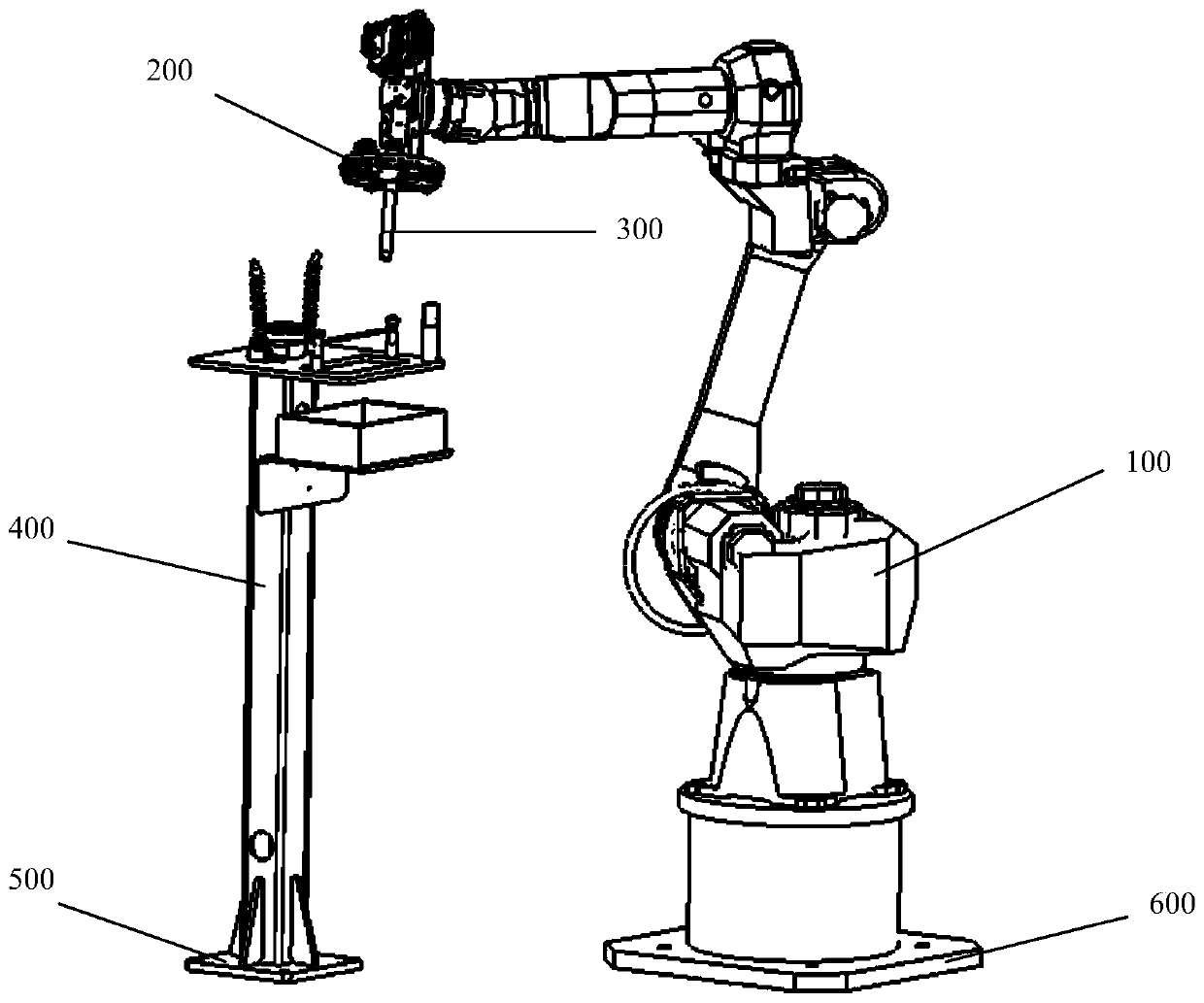

[0037] Such as figure 1 , 2 A new type of robot automatic gluing detection system shown includes a robot system 100, a 3D visual detection system 200, a gluing system 300, a communication module, a working platform 400, a two-dimensional code information sticker, and a binocular camera (in the figure not shown), the robot system base 500 and the work platform base 600.

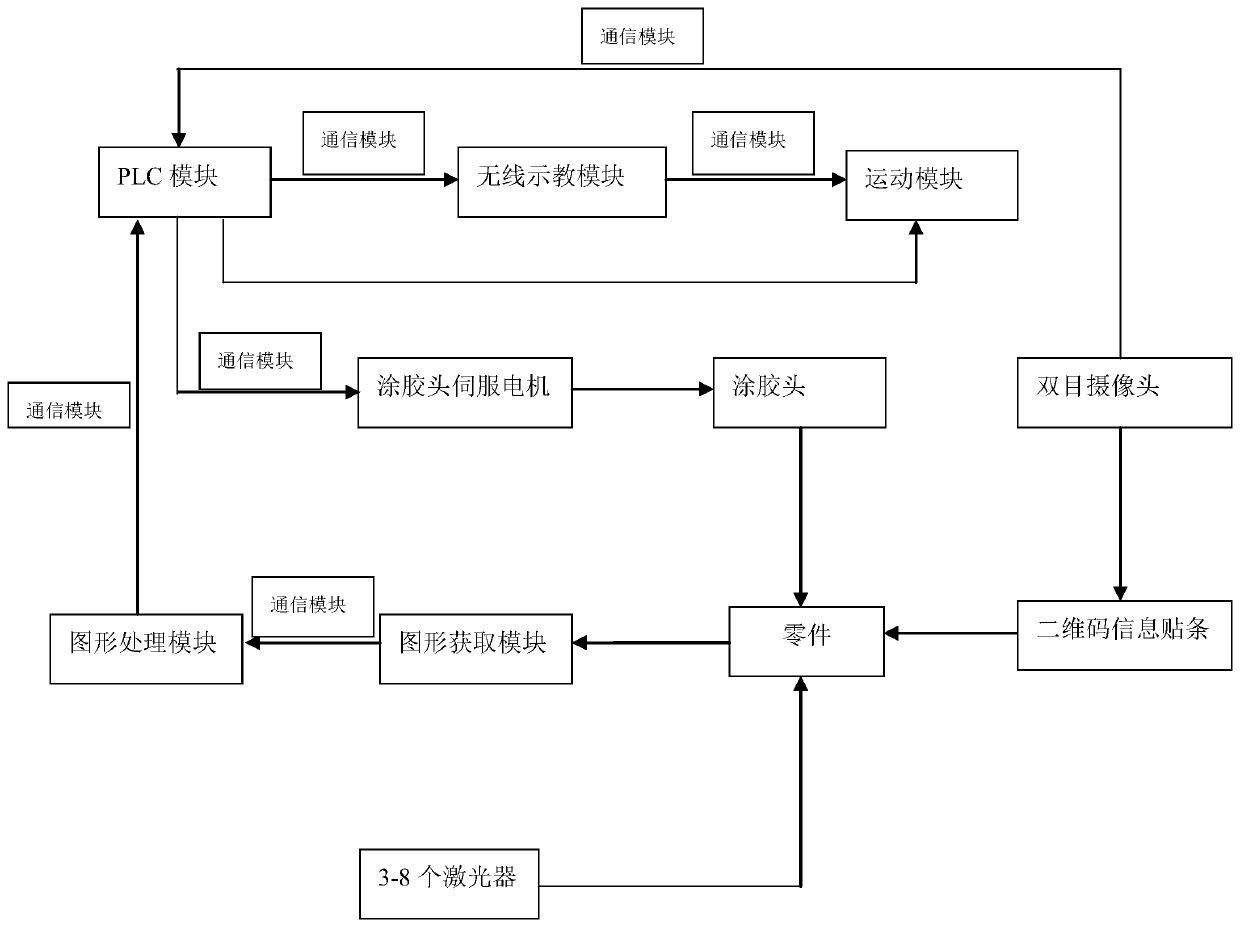

[0038] (1) The robot system 100 includes a PLC module, a wireless teaching module, and a motion module. The PLC module and the wireless teaching module are installed on the main body of the robot system, and the motion module is installed on the end of the robot system 100 .

[0039] The PLC module issues execution commands to the wireless teaching module, motion module, and gluing system; accepts and processes feedback information from the 3D visual graphics processing module.

[0040] The wireless teaching module performs wireless teaching operations on the motion module after receiving commands from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com