Hydraulic control for a molding unit of an injection molding machine, and method for controlling a molding unit of an injection molding machine

A technology of hydraulic controller and injection molding machine, which is applied in the field of hydraulic controller and can solve problems such as valve operation wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

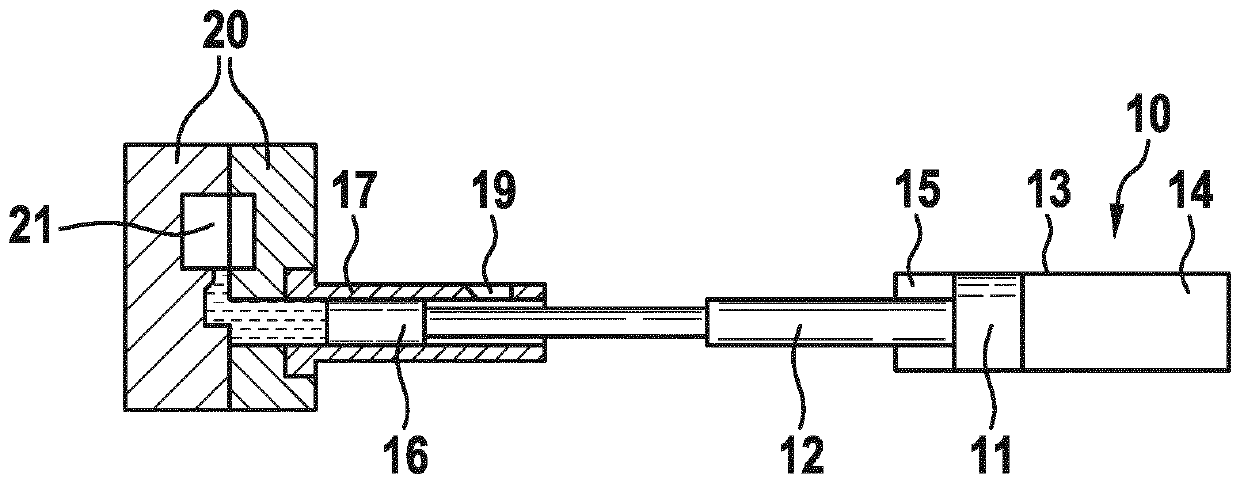

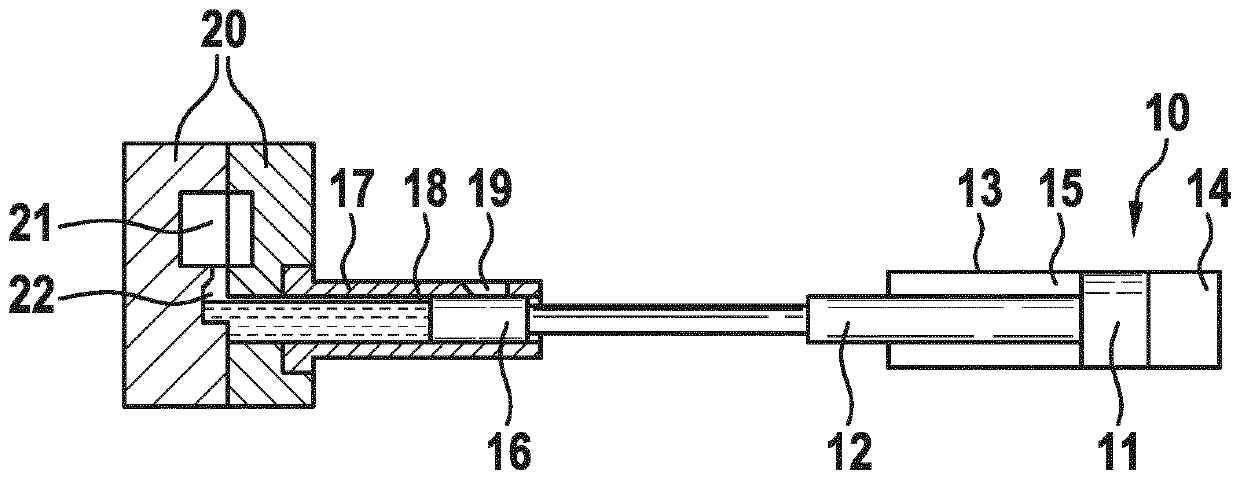

[0028] according to Figure 1 to Figure 4 , the die-casting machine comprises a casting cylinder 10 which is configured as a differential cylinder and has a piston 11 and a piston rod 12 which extends from the side of the piston 11 through the interior of the casting cylinder and at the cover from the The casing 13 protrudes outward. In the interior of the casting cylinder 10 , a completely cylindrical bottom-side pressure chamber 14 and an annular rod-side pressure chamber 15 are separated from each other by a piston 11 .

[0029] Fastened on the piston rod 12 is a cast piston 16 which is linearly movable in an injection chamber 18 which is formed in the injection sleeve 17 . In the injection sleeve 17 is located a filling opening 19 for a liquid or pasty molding compound, from which the workpiece to be formed is to be formed. The injection sleeve 17 is assembled with a mold 20 by means of which a mold cavity 21 is formed which can be filled with molding material for the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com