Surface type reverse osmosis membrane filter element

A reverse osmosis membrane, surface technology, applied in reverse osmosis, semi-permeable membrane separation, osmosis/dialysis water/sewage treatment, etc., can solve the problems of technical solution limitations, ignoring purification efficiency, etc., to enhance filtration effect, water quality Improve, improve the effect of filtering speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

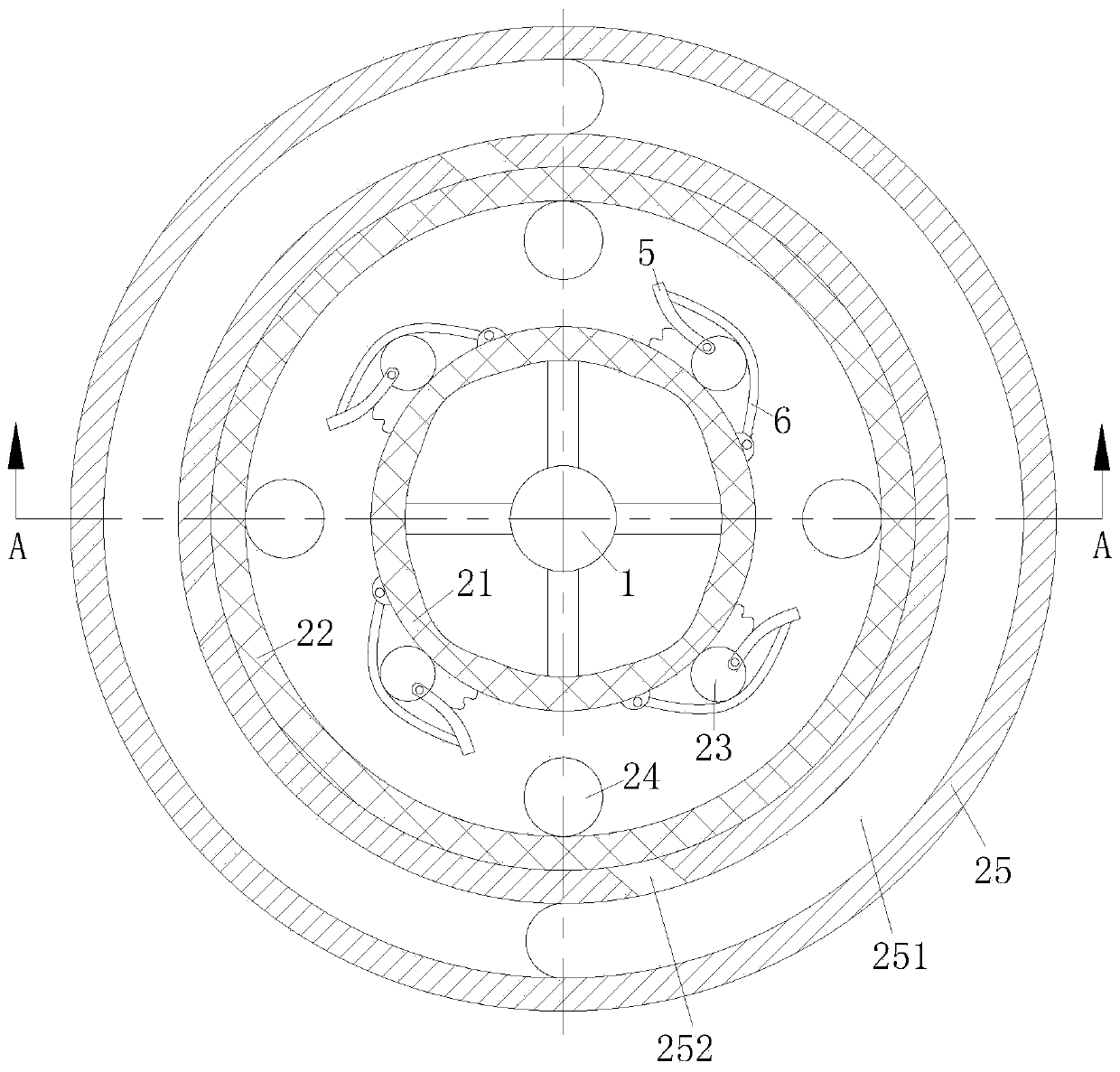

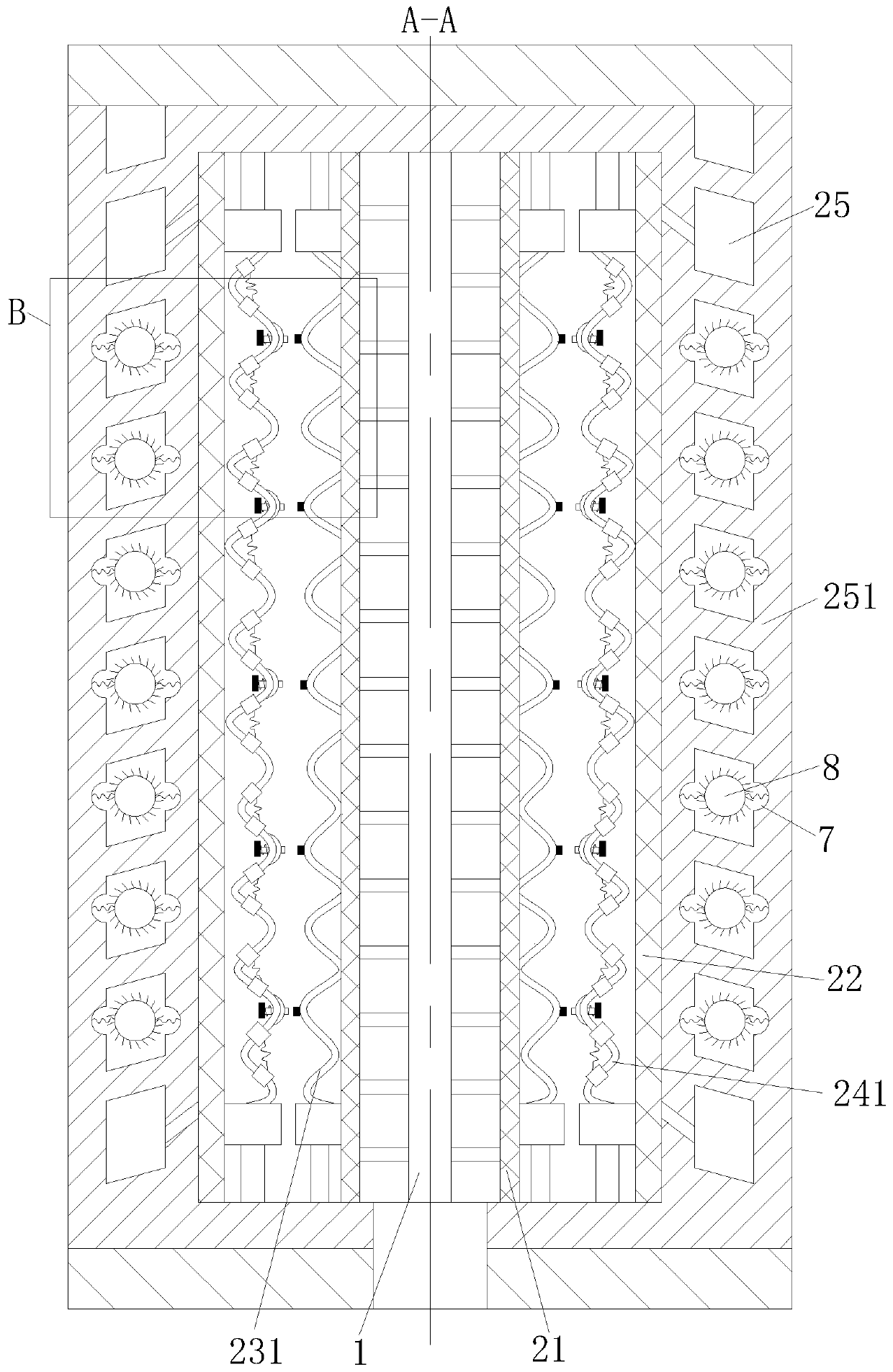

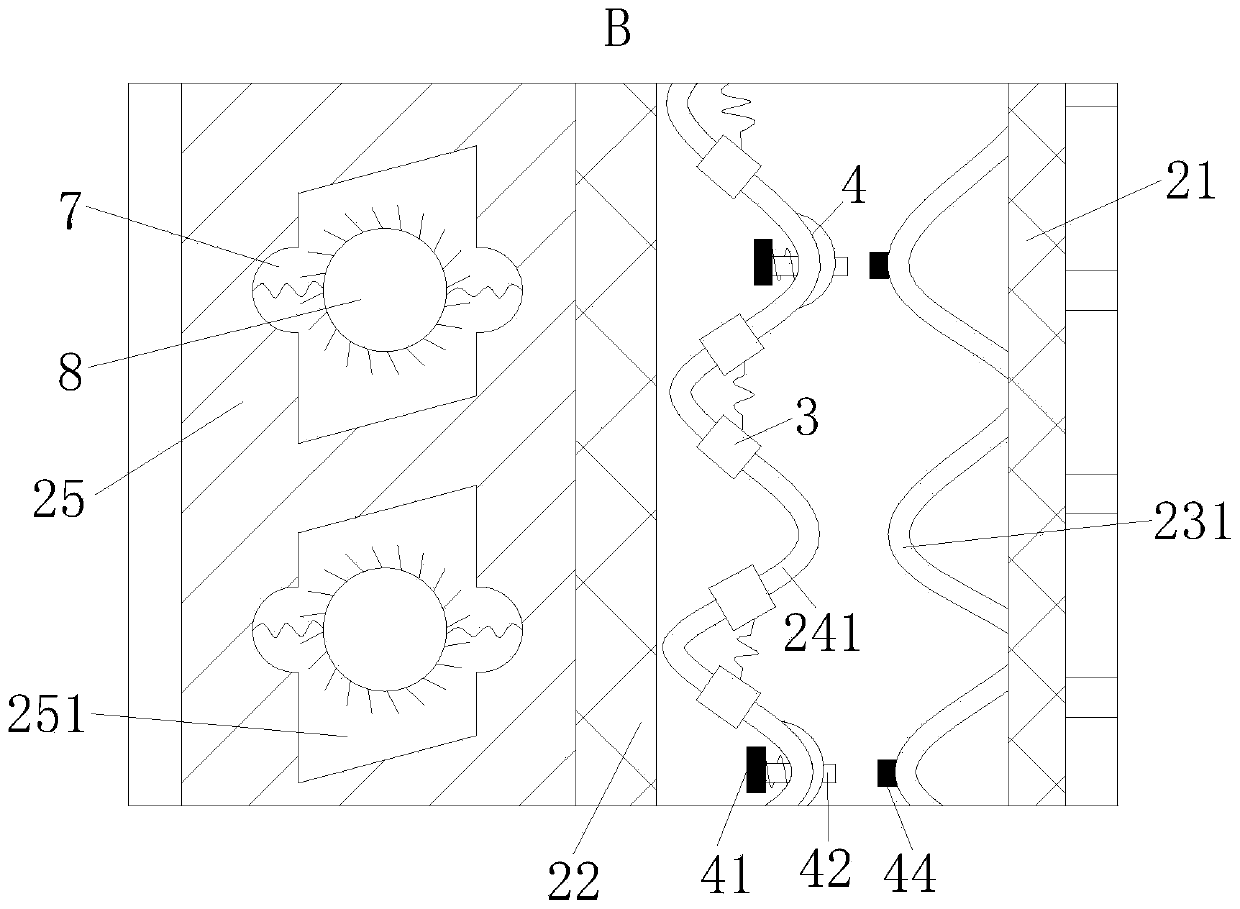

[0021] Such as Figure 1 to Figure 3As shown, a surface-type reverse osmosis membrane filter element according to the present invention includes a central tube 1 and a filter module 2; the bottom of the central tube 1 is provided with a clean water outlet; the filter module 2 is located on the outer ring of the central tube 1 , the filter module 2 is used to filter water, and the filter module 2 includes an inner filter membrane 21, an outer filter membrane 22, a No. 1 roller 23, a No. 2 roller 24 and a sleeve 25; 1 outer ring, and the inner filter membrane 21 and the central tube 1 are connected by a bracket, and a group of No. 1 rollers 23 are evenly distributed on the outer ring of the inner filter membrane 21; the outer filter membrane 22 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com