Chemical synthesis reaction kettle with shaft-free stirring function

A technology of chemical synthesis and shaftless stirring, which is applied in chemical/physical/physical chemical fixed reactors, chemical instruments and methods, control/regulation processes, etc., and can solve the problem of excessively high design requirements for the strength of the stirring shaft and limited stirring blades Diameter and other issues to achieve the effect of solving the leakage problem of the mechanical seal, improving the mixing effect and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below.

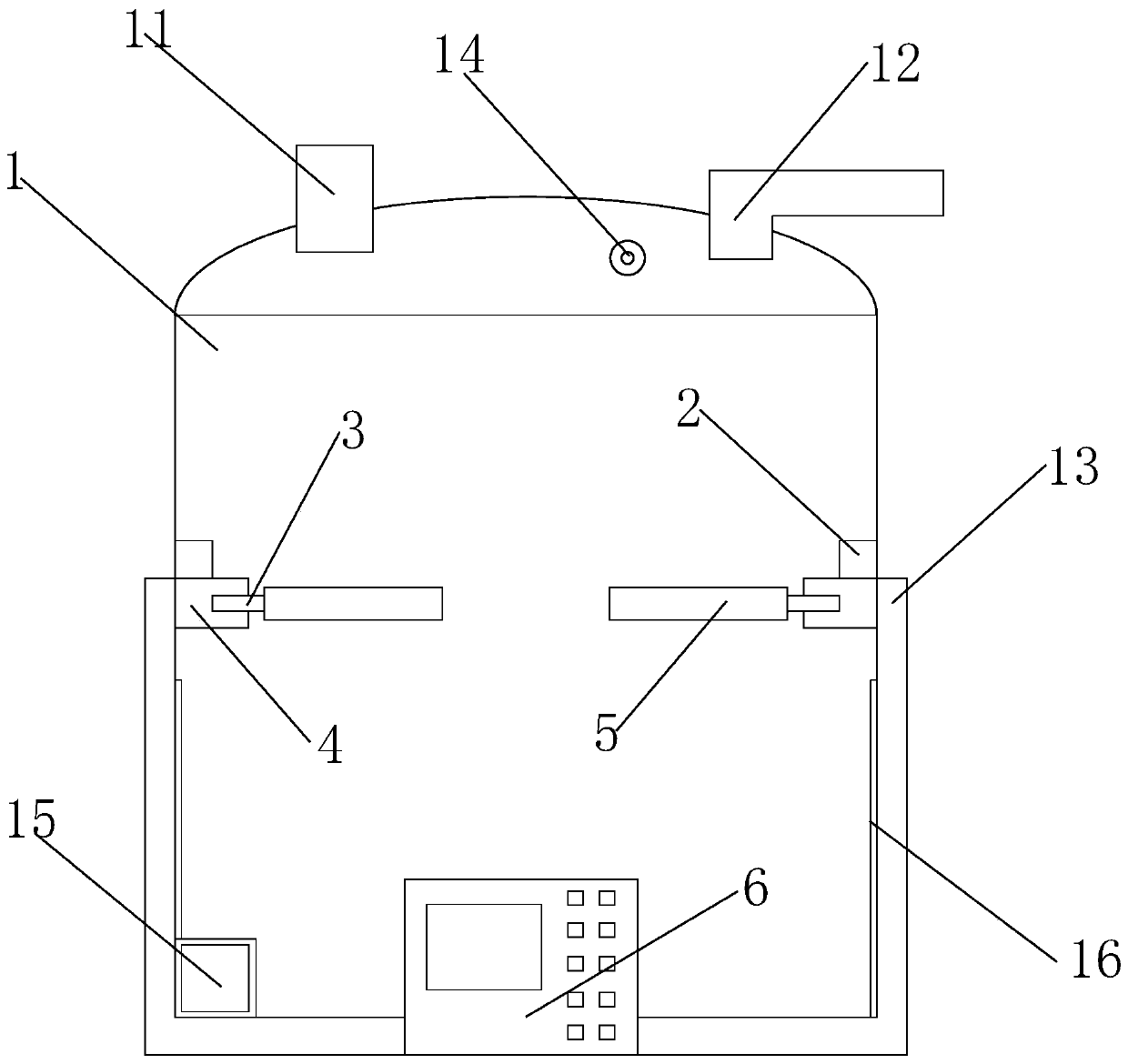

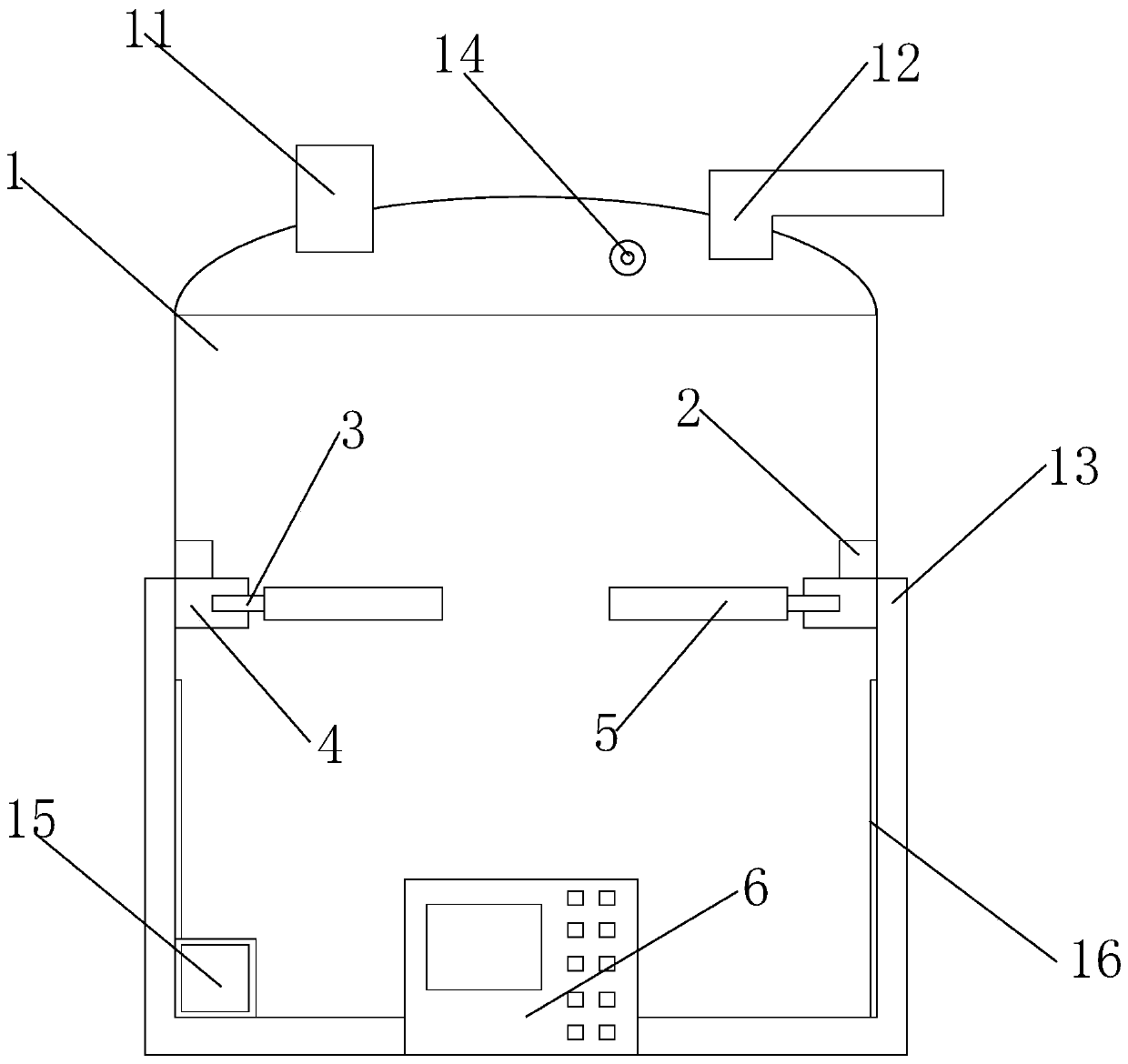

[0018] refer to figure 1 , a chemical synthesis reaction kettle without shaft stirring, comprising a kettle body 1 and a motor 2, the interior of the kettle body 1 is provided with a working chamber, and the top and bottom ends of the kettle body 1 are respectively provided with a feed pipe 11 and a The discharge pipe 12 also includes a rotating device 3, a supporting device 4 and a stirring device 5, the supporting device 4 is fixedly arranged on the inner wall of the kettle body 1, the motor 2 is fixed on the supporting device 4, and the rotating The device 3 is movably arranged on the support device 4, the output end of the motor 2 is provided with driving teeth, and the upper part of the inner wall of the rotating device 3 is provided with passive teeth matching the driving teeth, and the driving teeth are matched with the driving teeth. The rotating device 3 is meshed and connected, and the stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com