Production equipment of heat preservation and disassembly-free formwork for construction engineering infilled wall

A technology that avoids demolition of formwork and construction engineering. It is applied in metal processing equipment, drilling/drilling equipment, manufacturing tools, etc. It can solve the problems of long clamping time, etc., and achieve safe and convenient use, easy adjustment, and scientific structure. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

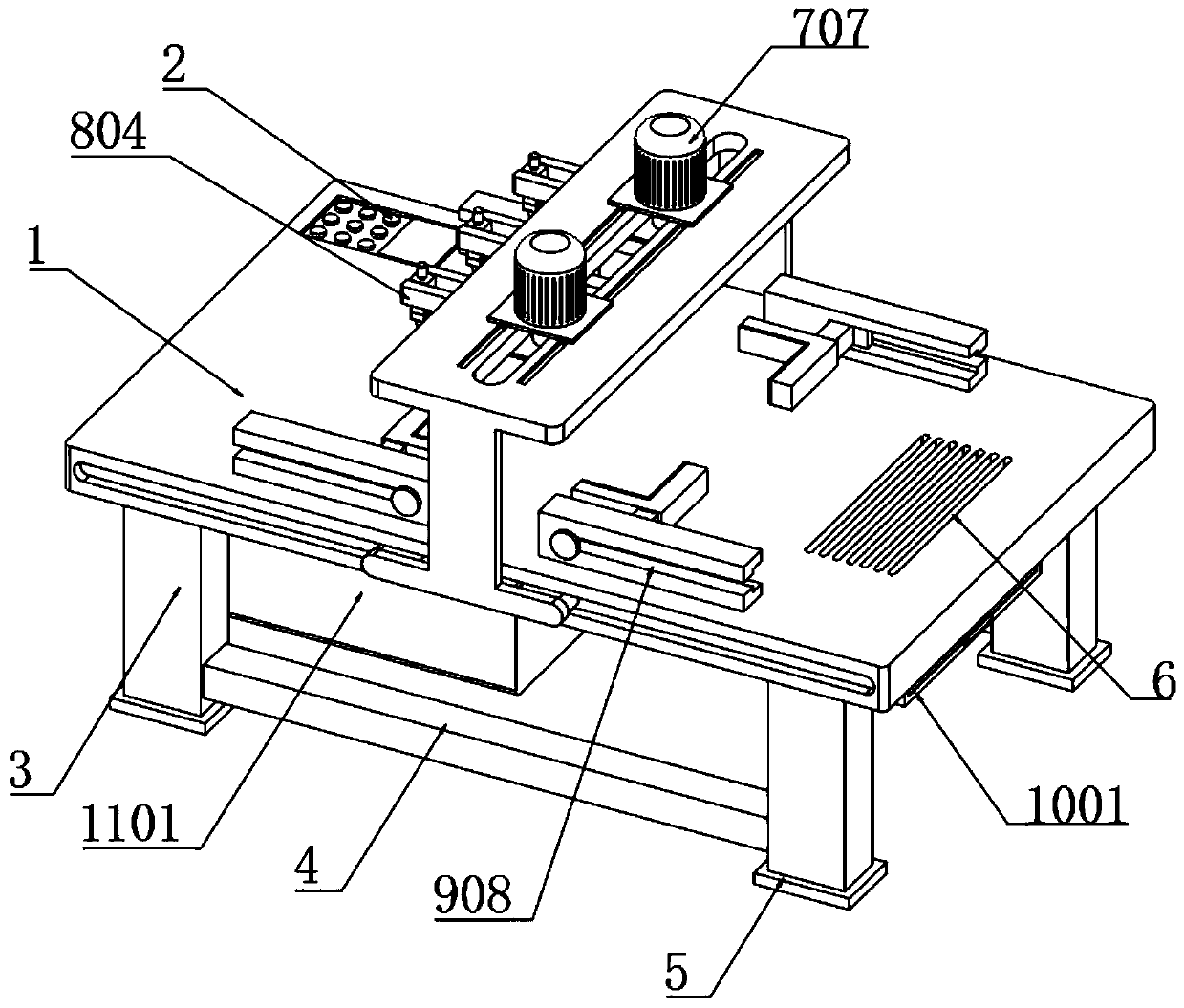

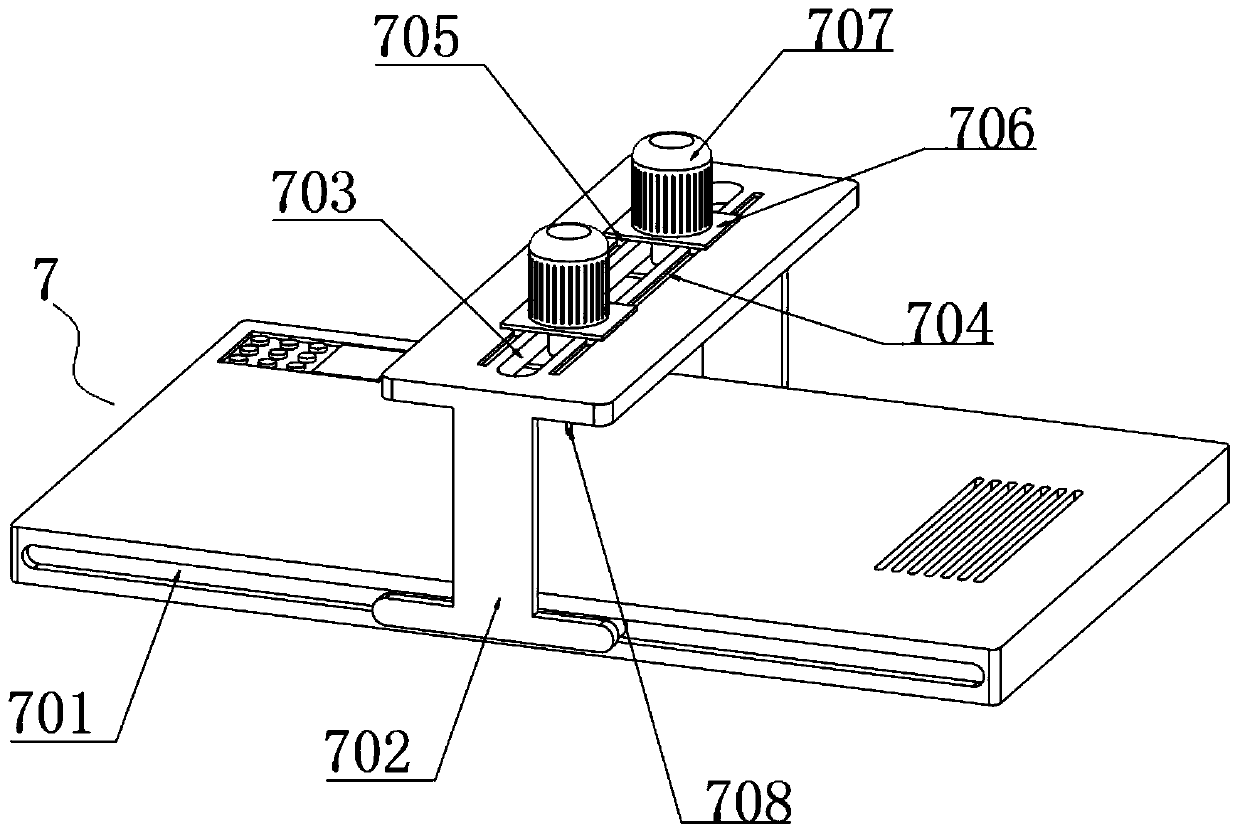

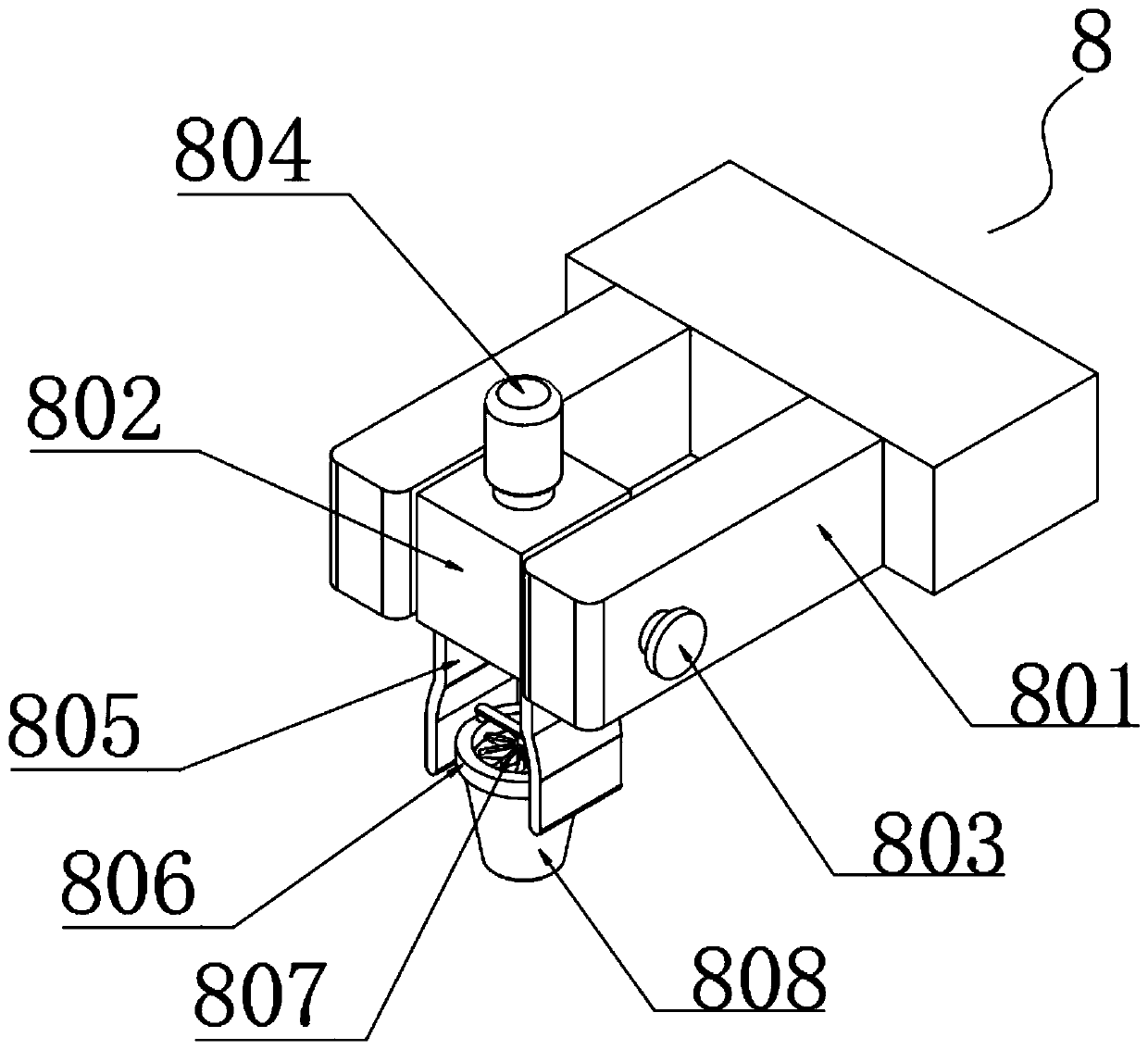

[0043] Example: such as Figure 1-6As shown, the present invention provides a technical solution, a production equipment for thermal insulation and non-disassembly formwork for filling walls in construction engineering, including a work surface 1, a control switch 2 is embedded on the top side of the work surface 1, and the bottom of the work surface 1 The four corners of the end are symmetrically equipped with supporting columns 3, and the connecting columns 4 are fixedly connected between the supporting columns 3. The bottom of the connecting columns 4 is equipped with a non-slip foot pad 5, and the other side of the top of the work surface 1 is provided with a cle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap