Method for coating backing adhesive on cloth

A technology of pasting and cloth, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of low production efficiency, and achieve high production efficiency, simple operation steps, high resilience and stiffness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of method that cloth sticks adhesive back, it comprises the steps:

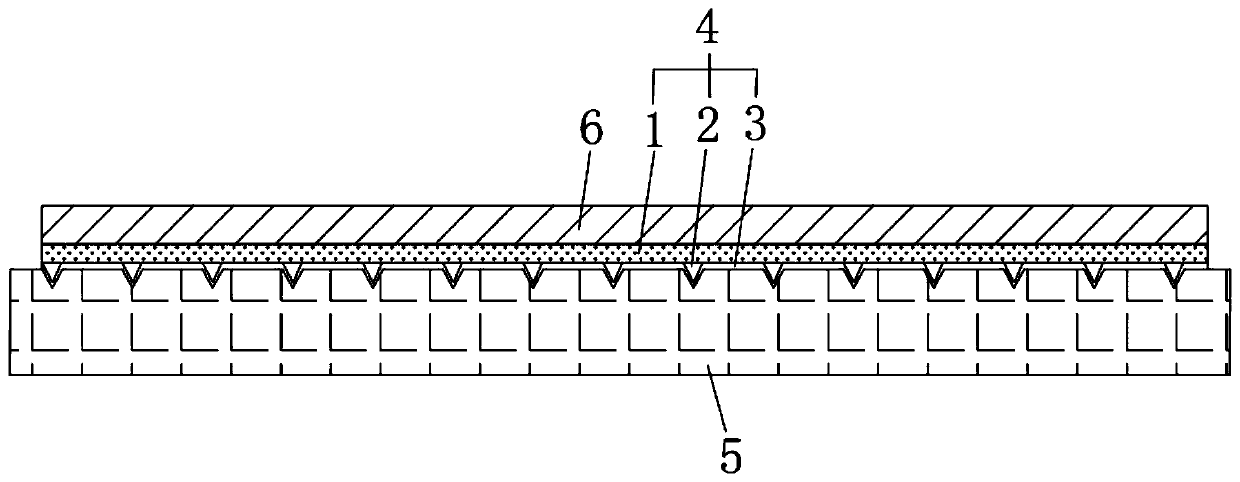

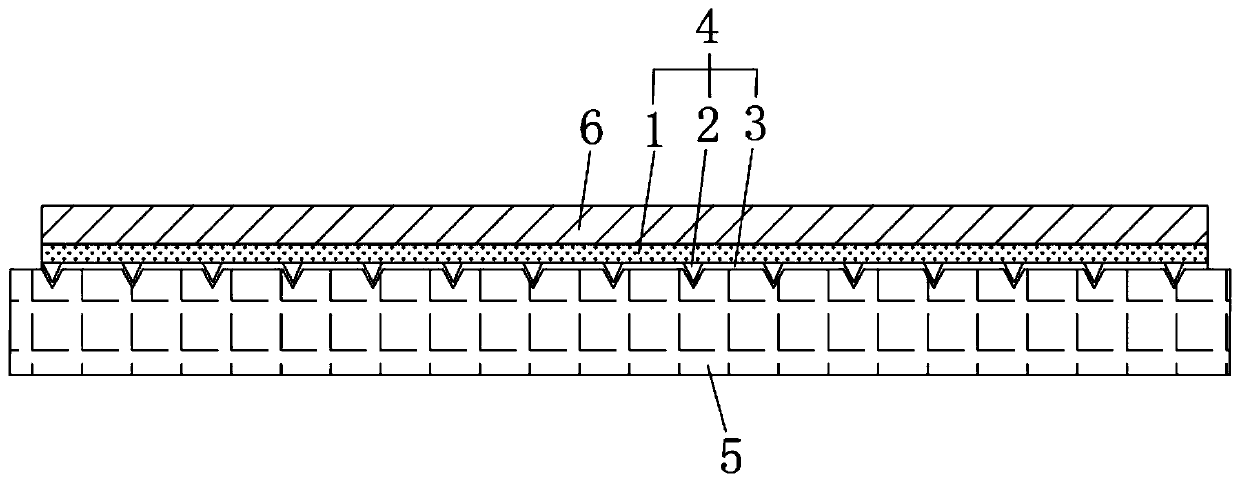

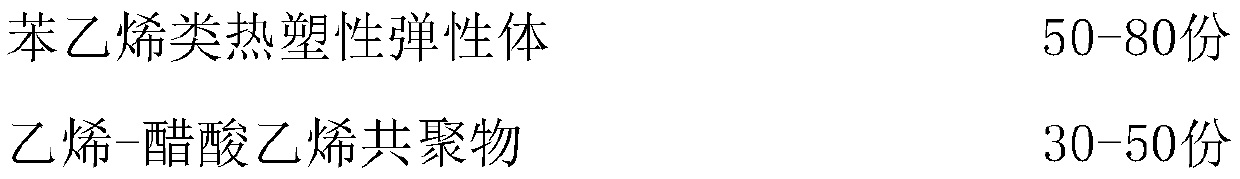

[0031] A. Preparation of hot melt adhesive diaphragm 4: Coat the first layer of adhesive liquid on the mold, then evenly sprinkle reinforcing filler 2 on the first layer of adhesive liquid, and raise the temperature to 60°C to solidify the first layer of adhesive liquid to form a matrix The film layer 1, then coat the second layer of adhesive liquid on the surface of the base film layer 1 and the reinforcing filler 2 and heat up to 60°C to solidify to form the reinforcing layer 3, and finally release the mold to obtain the hot-melt adhesive diaphragm 4;

[0032] B. Attach the reinforcing layer 3 of the hot melt adhesive diaphragm 4 prepared in step A to the cloth 5, then pressurize to 90MPa, pressurize for 0.75h, and raise the temperature to 180°C to melt the hot melt adhesive diaphragm 4, and finally Cooling and shaping, the temperature of cooling and shaping is 55°C, cooling for 1.1h, and a se...

Embodiment 2

[0044] A kind of method that cloth sticks adhesive back, it comprises the steps:

[0045] A. Preparation of hot-melt adhesive diaphragm: Coat the first layer of adhesive liquid on the mold, then evenly sprinkle reinforcing filler on the first layer of adhesive liquid, and raise the temperature to 60°C to solidify the first layer of adhesive liquid to form a base film layer , then apply a second layer of adhesive liquid on the surface of the base film layer and the reinforcing filler and heat up to 60°C to solidify to form a reinforcing layer, and finally demould to obtain a hot-melt adhesive diaphragm;

[0046] B. Lay the reinforcing layer of the hot-melt adhesive diaphragm prepared in step A with the cloth, pressurize to 80MPa, pressurize for 0.5h, and raise the temperature to 160°C to melt the hot-melt adhesive diaphragm, and finally cool to shape and cool The setting temperature is 50°C, and the semi-finished product is obtained after cooling for 1 hour;

[0047] C. Bond t...

Embodiment 3

[0057] A kind of method that cloth sticks adhesive back, it comprises the steps:

[0058] A. Preparation of hot-melt adhesive diaphragm: Coat the first layer of adhesive liquid on the mold, then evenly sprinkle reinforcing filler on the first layer of adhesive liquid, and raise the temperature to 60°C to solidify the first layer of adhesive liquid to form a base film layer , then apply a second layer of adhesive liquid on the surface of the base film layer and the reinforcing filler and heat up to 60°C to solidify to form a reinforcing layer, and finally demould to obtain a hot-melt adhesive diaphragm;

[0059] B. Lay the reinforcing layer of the hot-melt adhesive diaphragm prepared in step A with the cloth, pressurize to 100MPa, pressurize for 1h, and raise the temperature to 200°C to melt the hot-melt adhesive diaphragm, and finally cool and shape it. The temperature is 60°C, and the semi-finished product is obtained after cooling for 1.2h;

[0060] C. Bond the polyester al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com