Full-automatic adhesive tape slitting machine

A slitting machine, fully automatic technology, applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of reducing production efficiency, not realizing automatic slitting, etc., to improve production efficiency, save labor costs, The effect of improving the winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below with reference to the accompanying drawings.

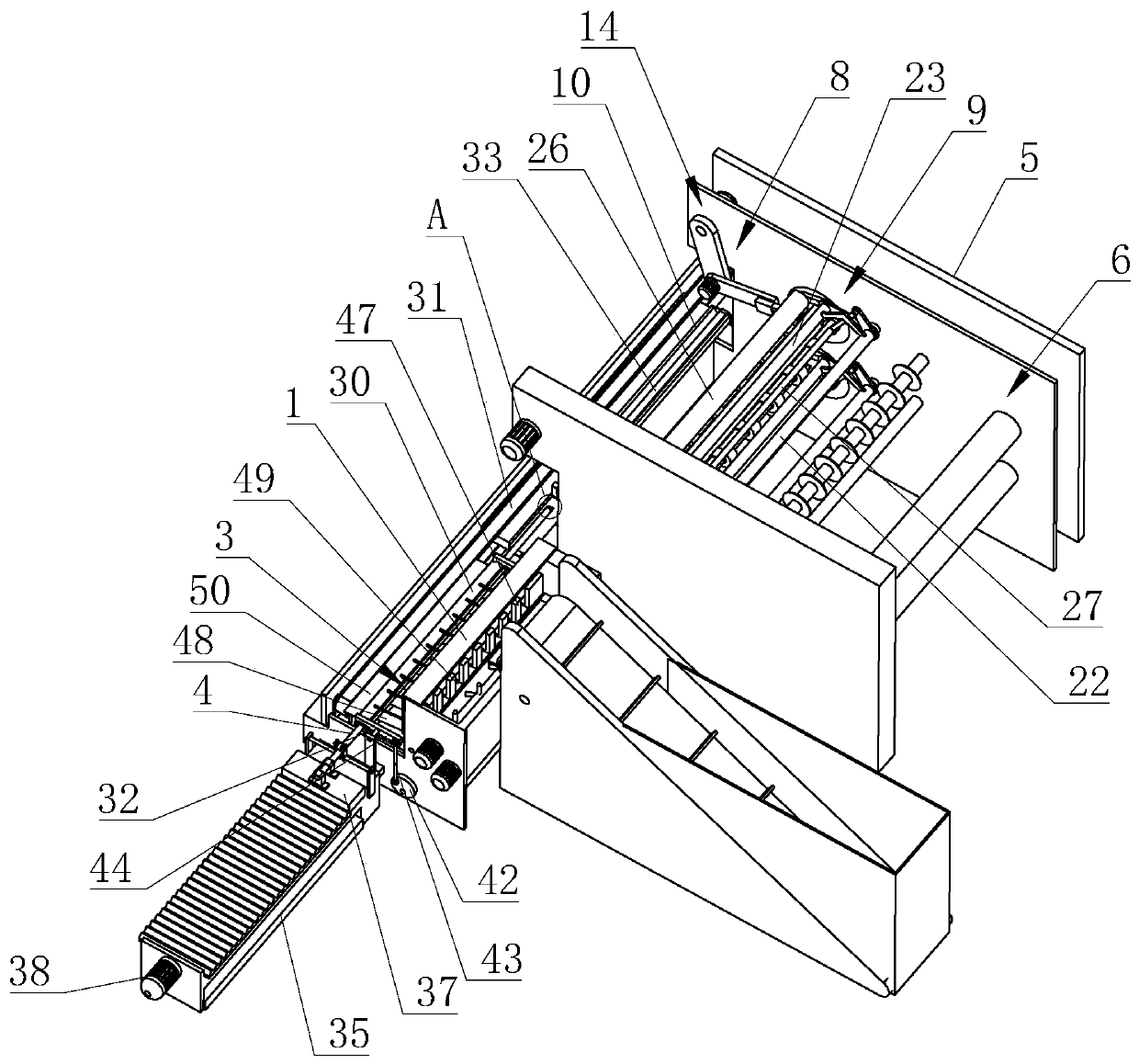

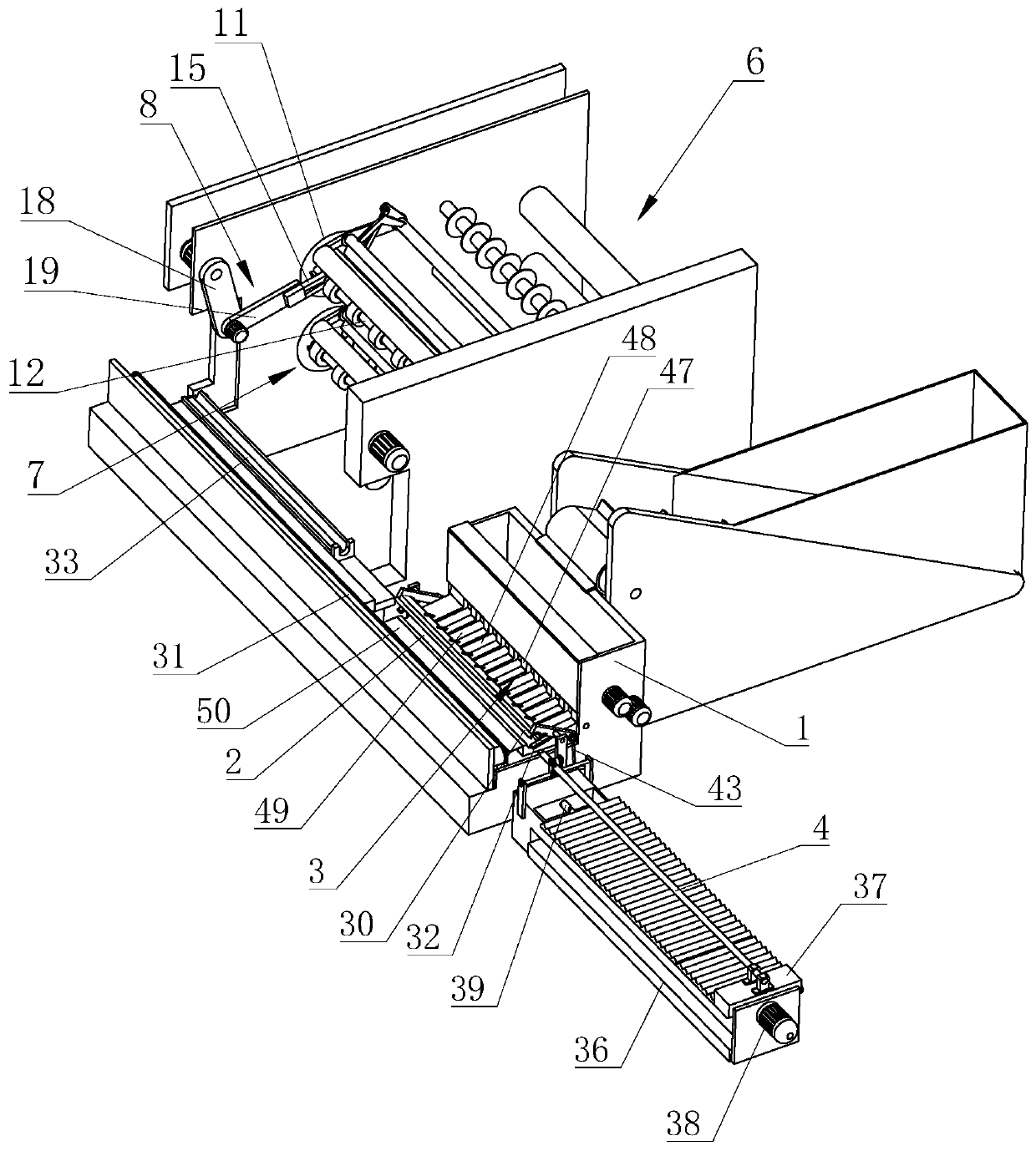

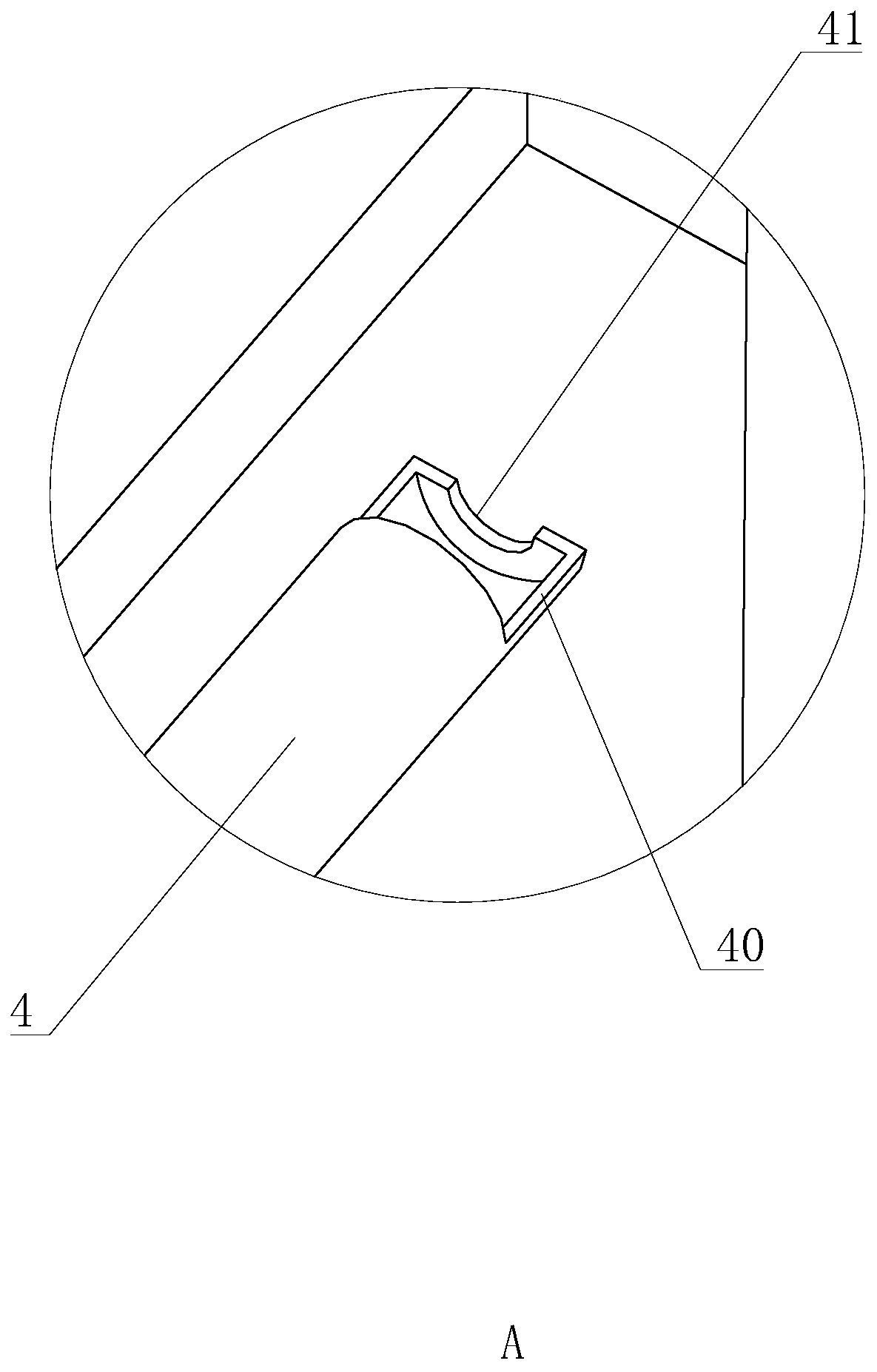

[0039] refer to figure 1 , which is a fully automatic tape slitting machine disclosed in the present invention, which includes an automatic paper tube loading mechanism and an automatic slitting mechanism. The automatic paper tube loading mechanism includes a carton box 1, a paper tube slot 2 and a guide slot plate 3 for connecting the discharge port of the carton box 1 and the paper tube slot 2. The guide slot plate 3 is an integrally formed vertical plate. 47 and the inclined plate 48, the vertical plate 47 and the inclined plate 48 are both provided with a number of guide grooves 49 for the paper supply cylinders to pass through. The vertical plate 47 extends into the collecting box from the discharge port at the bottom of the collecting box and It is fixedly attached to the side wall at the outlet of the collecting box. A push-pull rod 4 is slidably insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com