Preparation method of stimuli-responsive waterborne polyurethane emulsion with high water resistance

A water-based polyurethane and stimuli-responsive technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of polyurethane water resistance, poor water resistance, etc., to ensure stability, improve compactness and water resistance, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

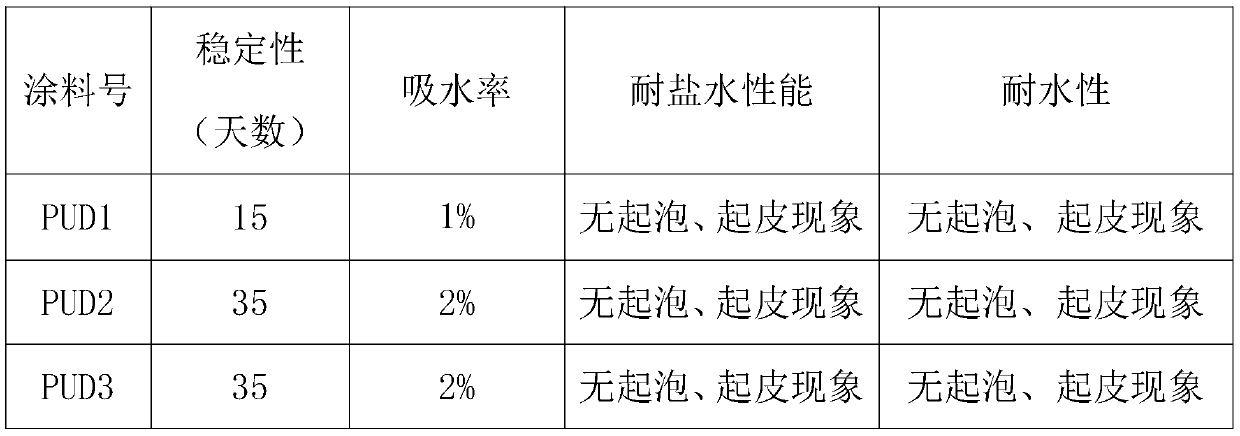

Examples

Embodiment 1

[0040] The preparation of the small molecule initiator that contains disulfide bond: 10g disulfide diol is dissolved in the mixed system of 40mL tetrahydrofuran and 40mL methylene chloride, after dissolving completely, add 9.2mL triethylamine to form solution A; 8.24g2- Bromo-2-methylpropionyl bromide was dissolved in 60mL of dichloromethane to form solution B, and solution B was added dropwise to solution A cooled in an ice bath within 30 minutes through a constant pressure dropping device, and reacted at room temperature for 24 hours; after the reaction, remove the generated salt by suction filtration, remove the solvent by rotary evaporation of the filtrate, rinse the crude product with deionized water, add anhydrous ether for extraction, take the oil phase, repeat washing / extraction 3 times, and use the organic phase obtained without Water MgSO 4 Dry for 4 hours to remove MgSO 4 Afterwards, the filtrate removes ether with rotary evaporation, obtains the small molecular in...

Embodiment 2

[0045] The preparation method of the small molecule initiator and the macromolecule initiator containing a disulfide bond is the same as that of Example 1.

[0046] Stimuli-responsive macromolecular emulsifier preparation: get the above-mentioned 10g macromolecular initiator, 100g hydrophilic monomer N-vinylpyrrolidone and add in the reaction vessel, then add 0.5g catalyst, 0.6g ligand PMDETA, 100mL acetone successively, and react The system was evacuated first, then filled with nitrogen or argon, and reacted at 90°C for 12 hours; after the reaction, the reaction mixture was passed through a neutral alumina column, and the solvent was removed by rotary evaporation, and the crude product was precipitated in ice n-hexane. Unreacted monomers were removed, and the precipitate was dried in a vacuum oven at 45°C for 24 hours to obtain stimuli-responsive emulsifier 2.

[0047] Preparation of stimuli-responsive waterborne polyurethane: the number average molecular weight M n 2000 PPG...

Embodiment 3

[0049] The preparation method of the small molecule initiator and the macromolecule initiator containing a disulfide bond is the same as that of Example 1.

[0050] Preparation of stimuli-responsive macromolecular emulsifier: preparation of stimuli-responsive macromolecular emulsifier: get above-mentioned 10g macromolecular initiator, 150g hydrophilic monomer N-vinylpyrrolidone and add in reaction vessel, then add 0.5g catalyst, 0.6 g ligand PMDETA, 100mL acetone, vacuumize the reaction system first, then fill it with nitrogen or argon, and react at 90°C for 12 hours; after the reaction, pass the reaction mixture through a neutral alumina column, and remove the solvent by rotary evaporation , the crude product was precipitated in ice n-hexane to remove unreacted monomers, and the precipitate was dried in a vacuum oven at 45°C for 24 hours to obtain stimuli-responsive emulsifier 3.

[0051] Preparation of stimuli-responsive waterborne polyurethane: the number average molecular ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap